Single-cylinder anti-rotation device and tunneling equipment

An anti-rotation, single-cylinder technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve the problems of easily damaged oil cylinders, and achieve the effect of simple working principle, reduced wear and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

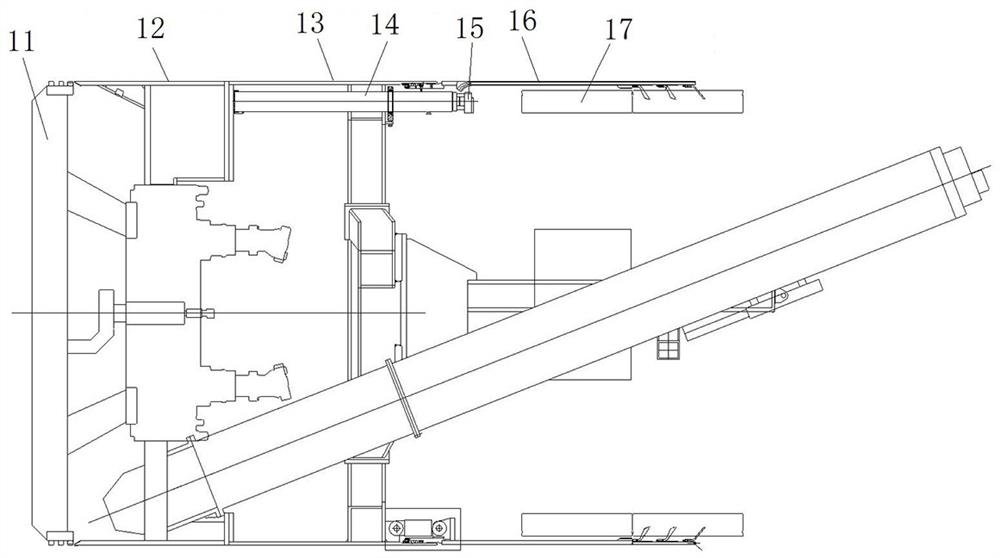

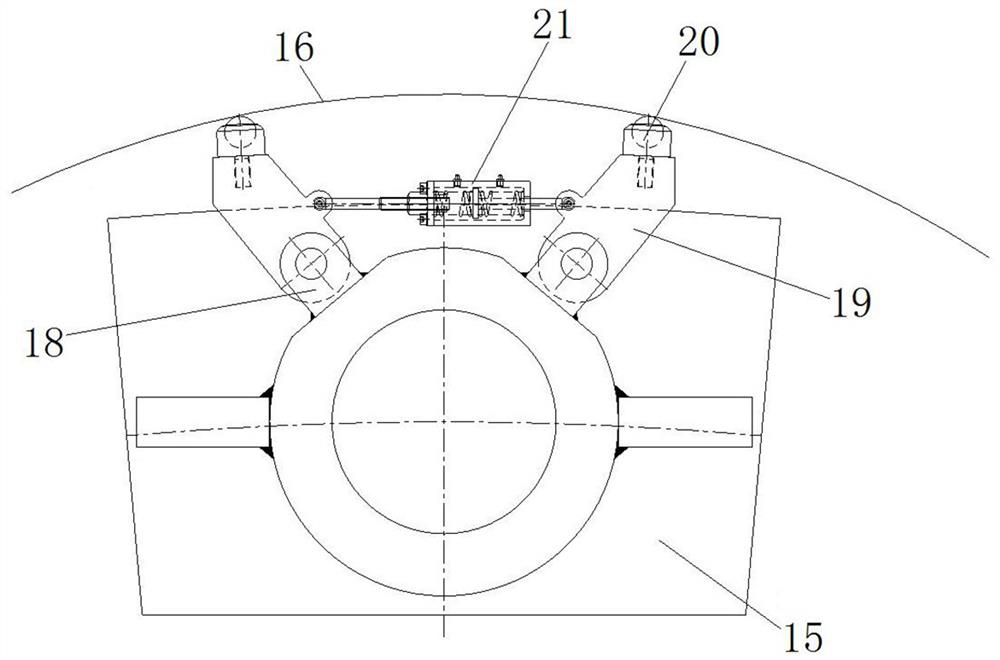

[0062] Prior to the introduction of the single cylinder anti-rotation device of the present invention, the structure of the prior art in the prior art, such as figure 1 As shown, the shield machine includes the front shield 12, the medium shield 13, and the tail shield 16. The front portion of the front shield 12 is provided with a cutter disk 11, and the medium shield 13 is fixed with a propulsion cylinder 14, and the telescopic rod of the cylinder 14 is propelled. There is a cylinder booth 15; the mounting of the tubic sheet 17 is carried out under the protection of the tail shield 16, and after the installation of each cyclic piece 17 is installed, the telescopic rod of the cylinder 14 projects, the cylinder head on the telescopic rod is pressed. On the mounted tube 17, the reaction force provided by the tube 17 is provided so that the shield is moved forward.

[0063] due to figure 1 The anti-rotation structure is not provided on the cylinder booth 15, and therefore, the teles...

Embodiment 2

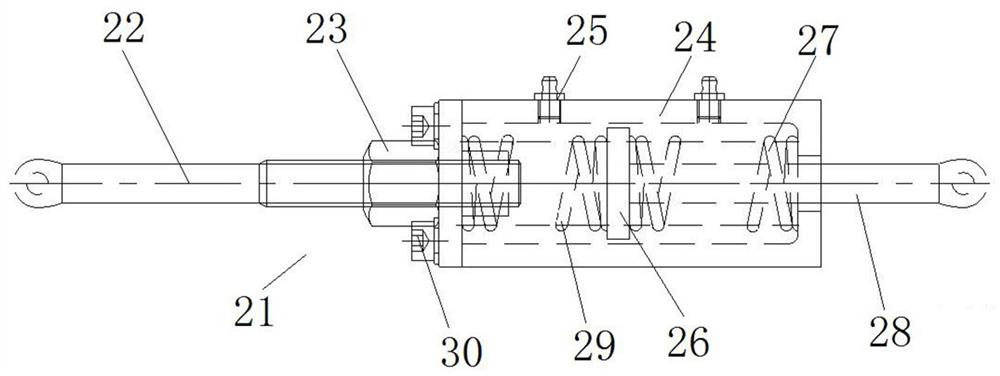

[0076] The difference from the first embodiment is that the first connection arm 22 is fixed to the sleeve 24 in the first connection arm 22, and the second connection arm 28 is slidably fitted in the sleeve 24, passed through the second connection arm 28 in the set. Slide in the cartridge 24 to achieve an angle change between the two connectors. In this embodiment, the first and second connections are slidably fitted within the sleeve, and the crossing arm is slid in the sleeve to achieve the angle change between the two connectors.

Embodiment 3

[0078] The difference from the first embodiment is that in the first embodiment, the first connection arm 22 has a threaded segment, and the first connection arm 22 is threaded on the sleeve 24 to regulate its axial position in the sleeve 24, and When the first connection arm 22 is adjusted to the sleeve 24 after the lock nut 23 is adjusted. In this embodiment, a planar surface is provided on the first connection arm, and a tight screw is provided, and the tight screw is adjusted radially in the sleeve. The first connecting arm is adjusted to the end cover by tightening the screw after adjustment. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com