Temperature control method based on slowest link

A temperature control method and link technology, applied in the direction of temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of glass kiln temperature control accuracy and insufficient uniformity, and achieve stable development and uniform control Requirements, effects of high-precision temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

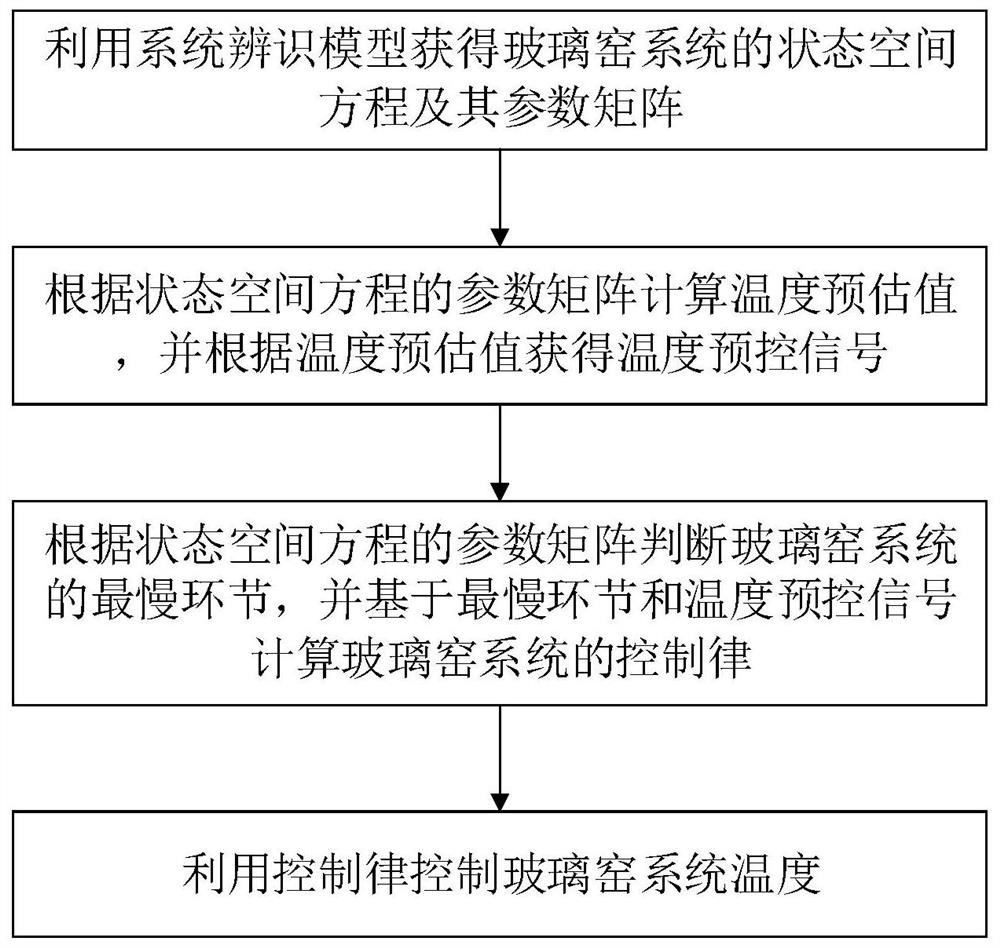

[0067] The present invention proposes a temperature control method based on the slowest link, such as figure 1 As shown, it specifically includes the following steps:

[0068] Step A, using the system identification model to obtain the state space equation and parameter matrix of the glass kiln system.

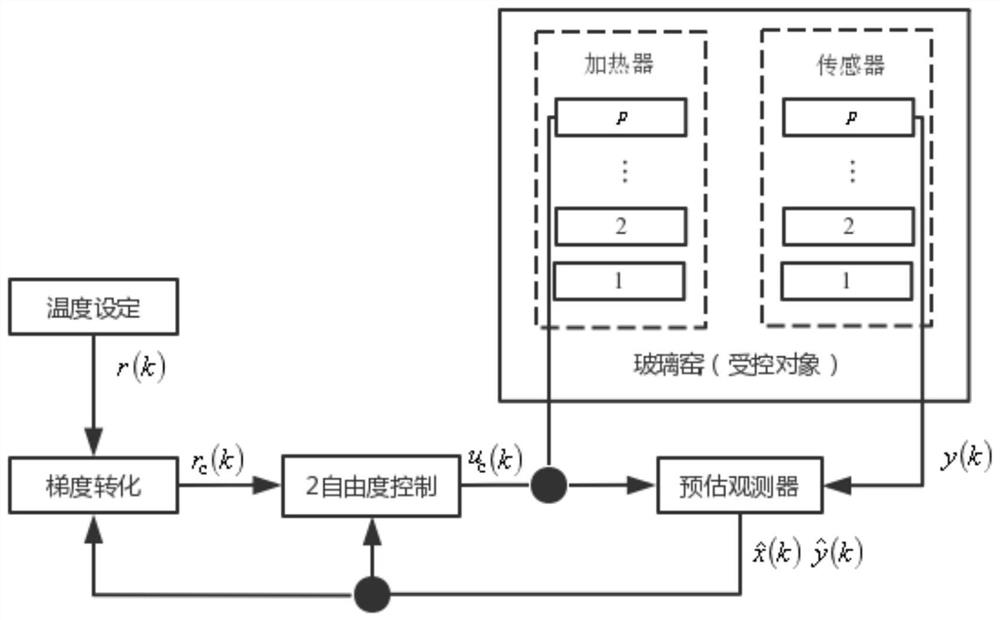

[0069] The glass kiln temperature control system in the embodiment of the present invention is as figure 2 As shown, the glass kiln is used as a temperature-controlled empty object, which includes p heaters and p sensors. The heaters are used to heat the glass, and the sensors are used to measure the temperature of the glass in real time. In the embodiment of the present invention, the temperature control of the glass kiln includes steps such as temperature setting, gradient conversion, 2-degree-of-freedom control, and predictive observation.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com