Method for the production of enzymes by a strain belonging to a filamentous fungus

A filamentous fungus and strain technology, applied in the directions of microorganism-based methods, methods of using microorganisms, biochemical equipment and methods, etc., can solve the problems of pH increase, disturbing the necessary adjustment of pH, laborious, etc., to achieve accurate size, increase usable The effect of volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

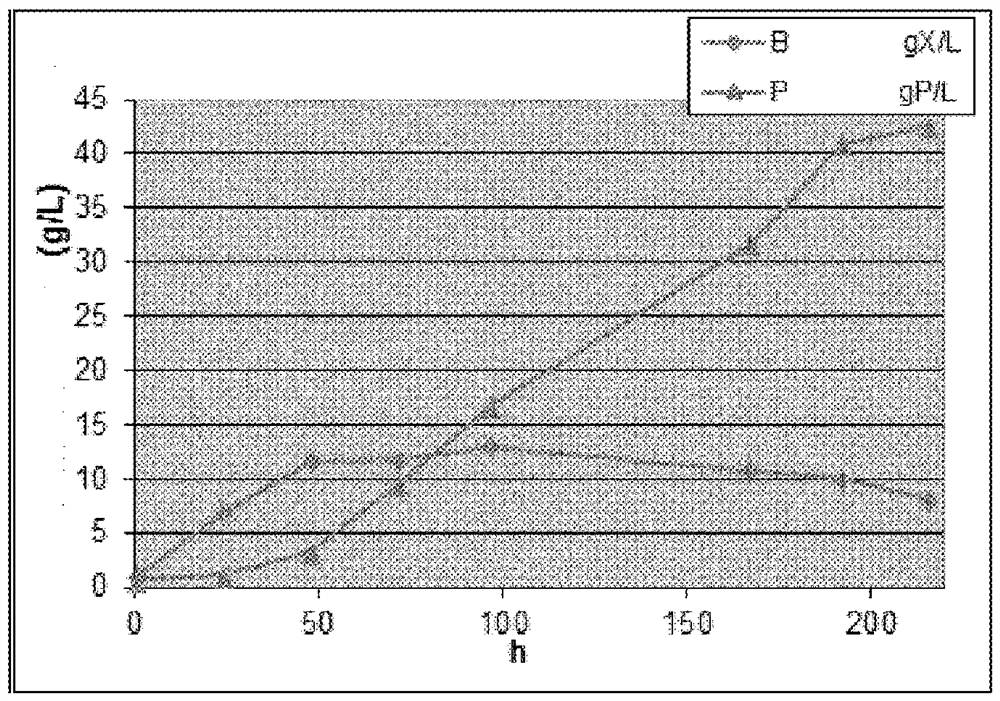

[0076] Example 1 was carried out starting with strain TR3002. This strain is described in the following publications: Ben Chaabane F, Jourdier E, Licht R, Cohen C and Monot F (2012) "Kinetic characterization of Trichoderma reesei CL847 TR3002: an engineered strain producing highly improved cellulolytic cocktail, Journal of Chemistry and Chemical Engineering6 ( 2), 109-117 and Ayrinhac C, Margeot A, Ferreira NL, Ben Chaabane F, Monot F, RavotG, Sonet J.-M and Fourage L (2011), "Improved saccharification of wheat straw forbiofuel production using an engineered secretome of Trichoderma reesei", Organic Process Research and Development 15 (1), 275-278.

[0077] - The growth phase was carried out at pH 4, 27°C with a glucose concentration of 15 g / L;

[0078] - The production phase was carried out at pH 4, 25°C with a lactose concentration of 220 g / L (equivalent to a specific fed-batch lactose flow rate of 45 mg per gram of biomass per hour).

Embodiment 2

[0079] Embodiment 2: (comparative example)

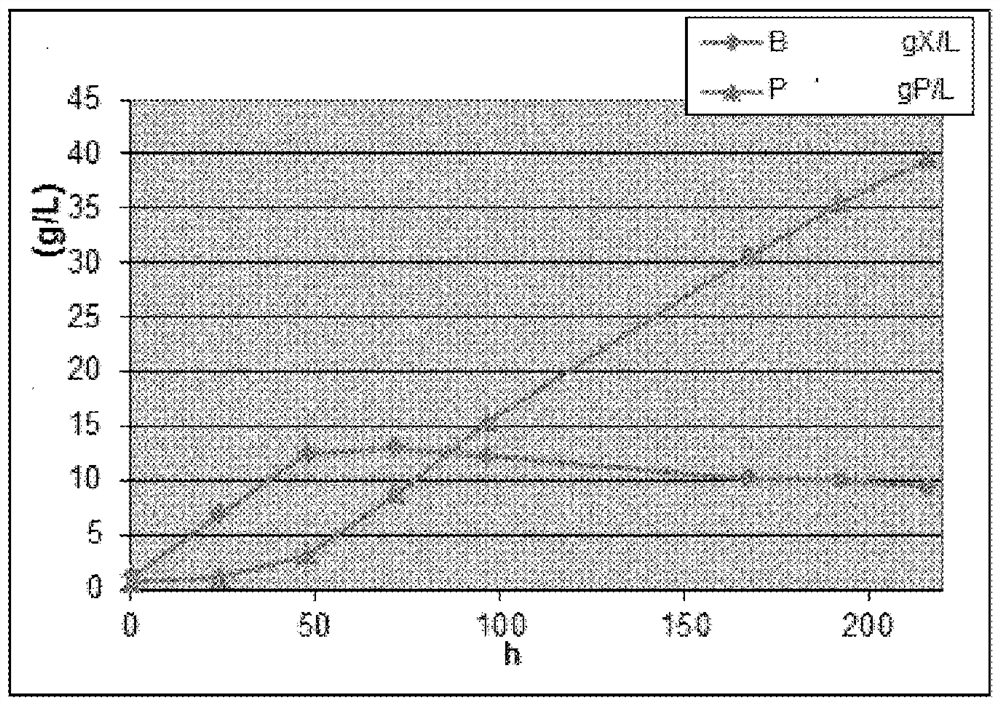

[0080] Example 2 was carried out starting with strain TR3002.

[0081] - The growth phase was carried out at a pH of 4.8 at 27°C with a glucose concentration of 15 g / L;

[0082] - The production phase was carried out at pH 4.8 at 25°C with a lactose concentration of 220 g / L (equivalent to a specific fed-batch lactose flow rate of 45 mg per gram of biomass per hour).

Embodiment 3

[0083] Embodiment 3: (comparative example)

[0084] Example 3 was carried out starting with strain TR3002.

[0085] - The growth phase was carried out at a pH of 5.5 at 27°C with a glucose concentration of 15 g / L;

[0086] - The production phase was carried out at pH 5.5 at 25°C with a lactose concentration of 220 g / L (equivalent to a specific fed-batch lactose flow rate of 45 mg per gram of biomass per hour).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com