Foreign substance inspection method and foreign substance inspection apparatus

A foreign matter inspection and foreign matter technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unconfirmed size, deterioration of lining yield, lack of safety management, etc., and achieve the effect of suppressing measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0041] -Lining-

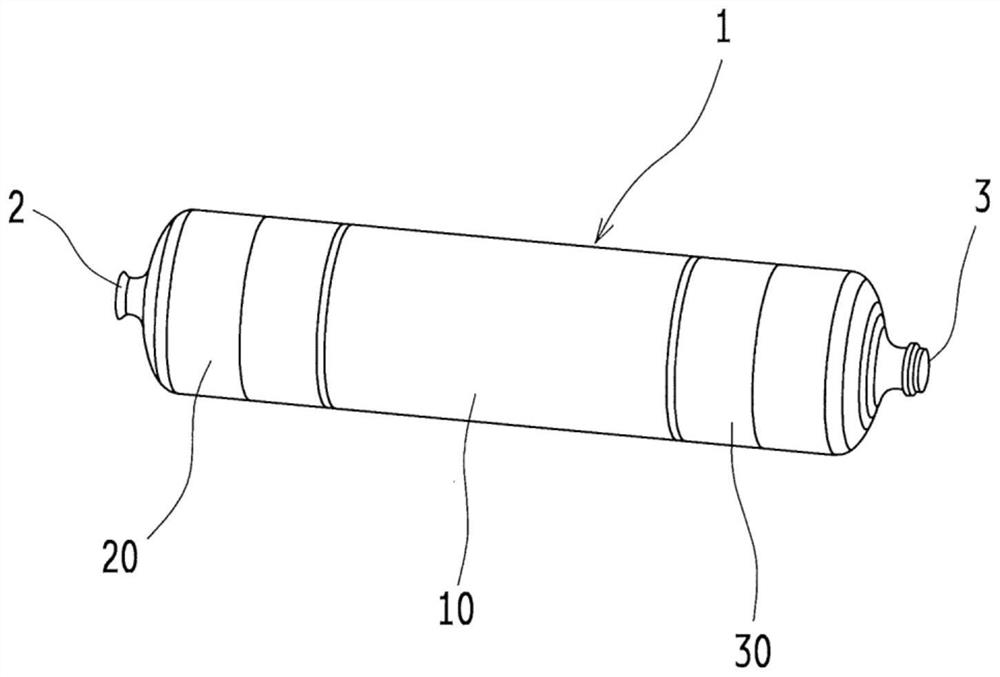

[0042] figure 1 It is a perspective view schematically showing the liner 1 of this embodiment. The inner liner 1 is, for example, a member constituting the inner casing of a hydrogen tank (not shown) mounted on a fuel cell vehicle, and is formed in a cylindrical shape with both ends closed, and can use the high-pressure gas used for power generation of the fuel cell in a sealed state. of hydrogen contained inside it.

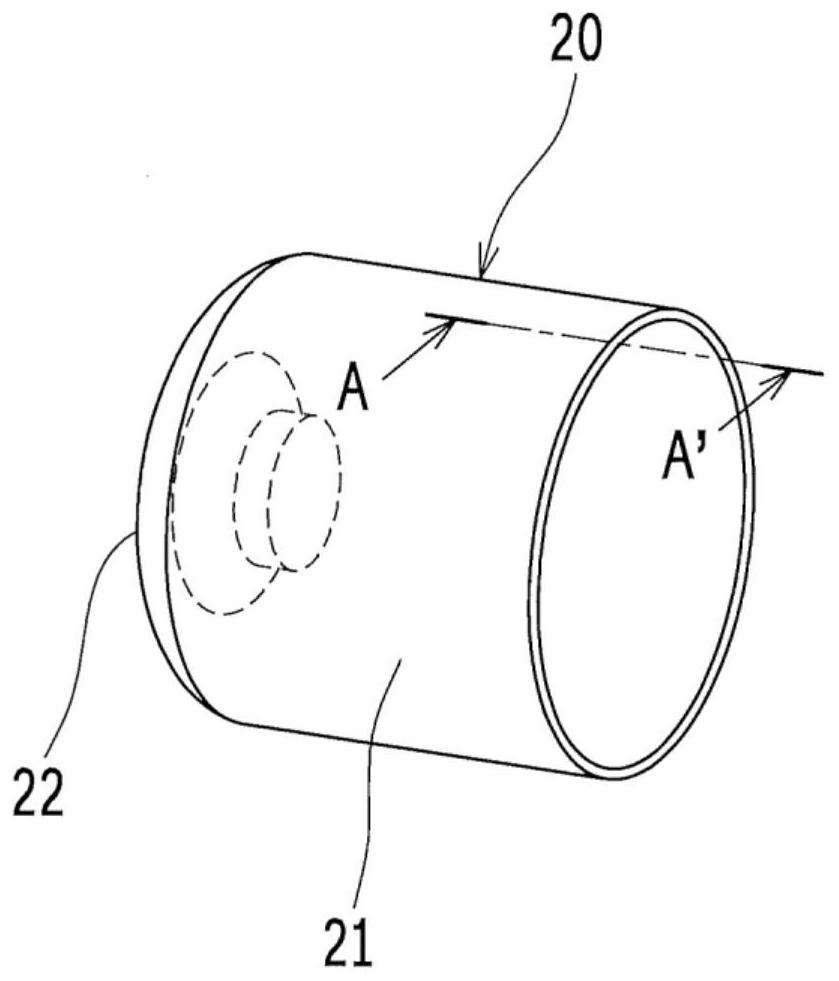

[0043] From the viewpoint of weight reduction, the lining 1 is made of resin, such as figure 1 As shown, a resin pipe 10 and two resin domes 20 and 30 are provided. These are joined (welded) in the axial direction so that one cylindrical tube 10 is sandwiched between two bottomed cylindrical domes 20, 30, and the aluminum joint 2, 3 is assembled to the two domes 20 and 30 located at both ends, whereby the liner 1 is formed into a closed cylindrical shape. Carbon fiber (not shown) is wound around the outer periphery of the inner liner 1 thu...

Embodiment approach 2

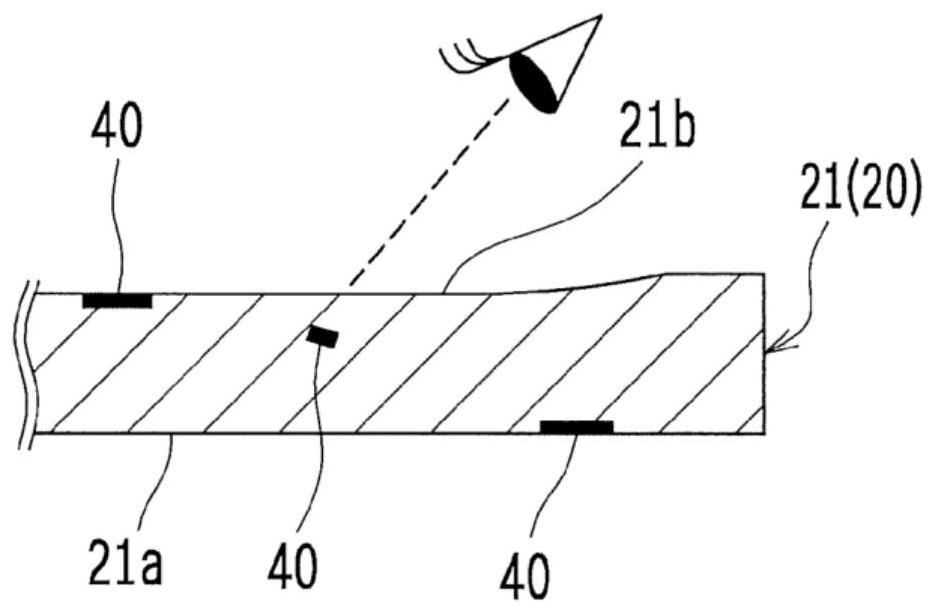

[0089] The difference between the present embodiment and the above-mentioned first embodiment is that the first projected image 41 projected by the inner light source 71 on the outer peripheral surface 21b of the dome 20 is also captured by the camera. Hereinafter, description will focus on points different from Embodiment 1. FIG.

[0090]The inspector can visually measure the size of the first projected image 41 formed by projecting the light from the inner light source 71 on the outer peripheral surface 21 b of the dome 20 regardless of the size of the diameter of the inner liner 1 . On the other hand, for the second projected image 42 formed by projecting the light from the external light source 73 onto the inner peripheral surface 21 a of the dome 20 , it may be difficult for the examiner to visually measure it due to the size of the diameter of the lining 1 . size. Therefore, in the above-mentioned first embodiment, the second projected image 42 projected on the inner pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com