Exposure apparatus, exposure method, and device fabricating method

An exposure device and exposure beam technology, applied in the field of component manufacturing, can solve problems such as insufficient focus matching and difficulty in matching image planes, and achieve good precision and suppress measurement errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

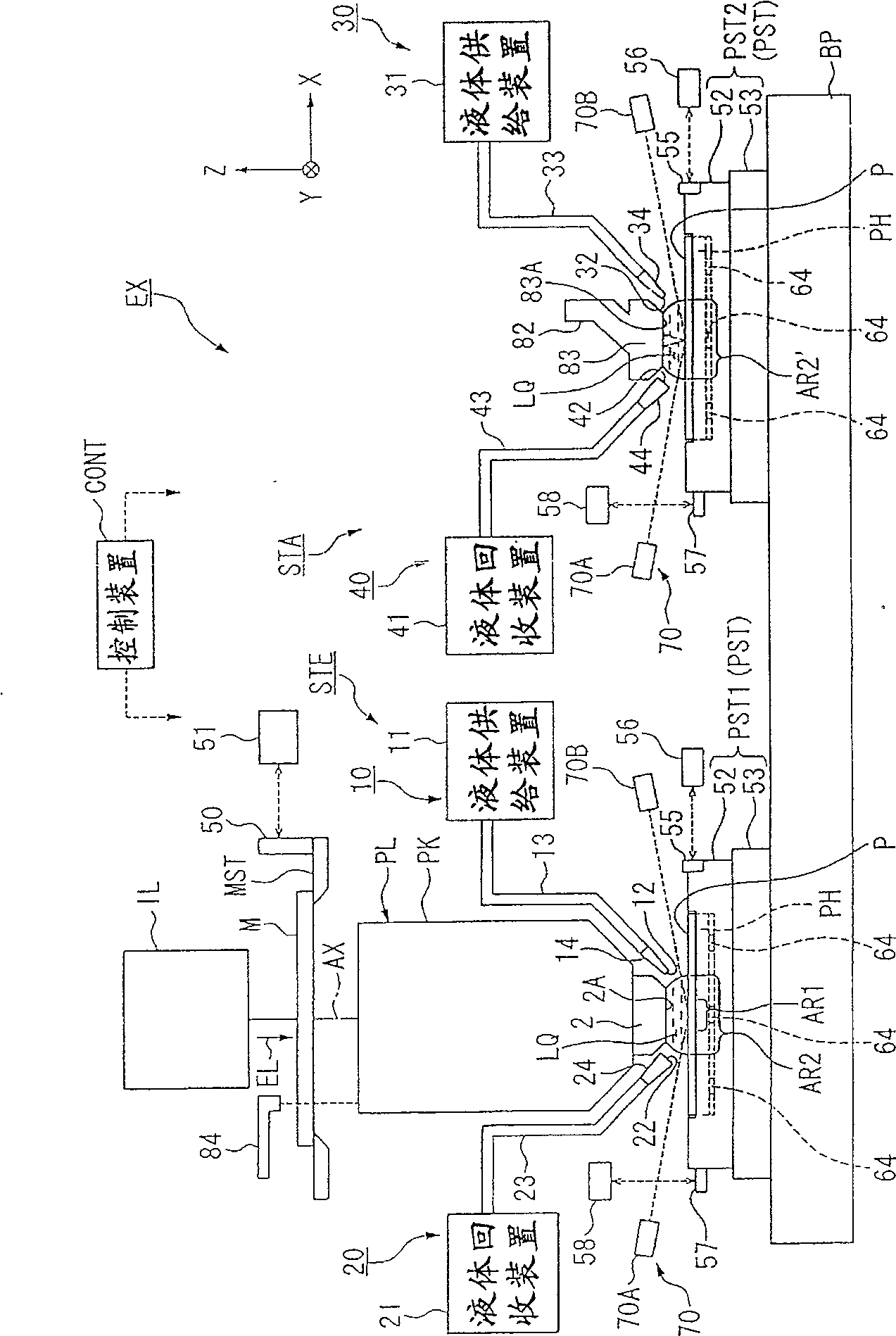

[0053] Hereinafter, the exposure apparatus of the present invention will be described with reference to the drawings. figure 1 It is a schematic configuration diagram showing an embodiment of the exposure apparatus of the present invention.

[0054] figure 1Among them, the exposure apparatus EX is a dual-stage exposure apparatus equipped with two substrate stages, and includes: a first substrate stage PST1 and a second substrate stage PST2 that can move independently on a common base BP, and each can hold And move the substrate P. In addition, this dual-stage exposure apparatus EX includes: an exposure station STE for exposing the substrate P held on the first substrate stage PST1 (or the second substrate stage PST2) through the projection optical system PL and the liquid LQ; The measurement station STA measures the second substrate stage PST2 (or the first substrate stage PST1 ) or the substrate P held on the substrate stage PST2 ( PST1 ).

[0055] By moving the first su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com