Display method of quenched original austenite grain boundaries of low-carbon steel

A technology of austenite grain boundary and display method, which is applied in the direction of measuring devices, instruments, particle size analysis, etc., and can solve the problem that the original austenite grain size cannot be accurately calculated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

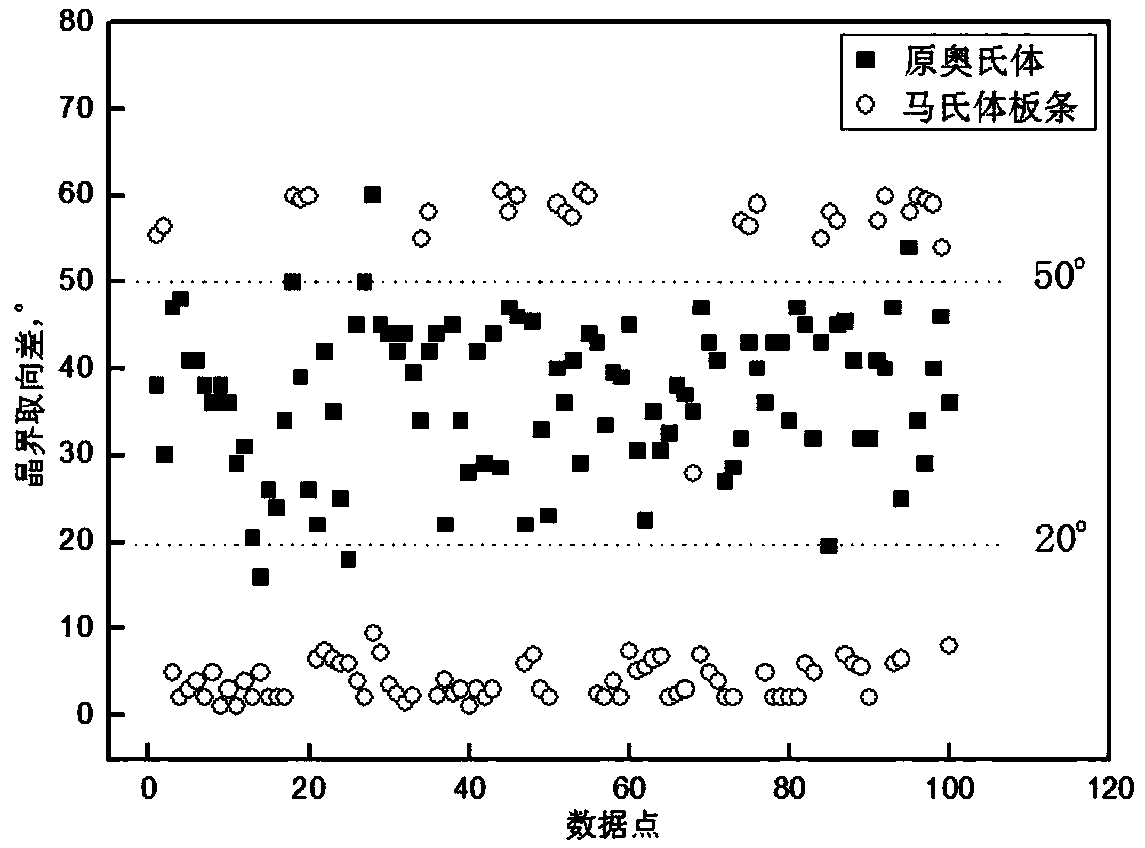

[0015] In this embodiment, the accurate austenite grain size is calculated after the low-carbon Nb-containing steel has a carbon content of 0.88wt%, and the size, shape and distribution characteristics of the quenched prior austenite grains are clearly displayed. The specific technical steps and parameters are:

[0016] 1. Sample preparation: The sample is a low-carbon steel quenched sample. The sample size requires a length of 10mm, a width of 8mm, and a thickness of 2mm. The upper and lower surfaces are guaranteed to be parallel. The residual stress is removed by electrolytic polishing on the surface, and finally a flat, clean and bright surface is obtained. Surface scanning of polished surfaces.

[0017] 2. Electron microscope parameters: In order to obtain a clearer Kikuchi pattern, it is necessary to set the parameters of the electron microscope. According to the EBSD analysis, the parameters of the electron microscope are acceleration voltage 15kV, beam current 5nA, sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com