Multipurpose reaction kettle for chemical production

A chemical production and multi-purpose technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as blockage of the discharge port, achieve simple structure, improve reaction Efficiency and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

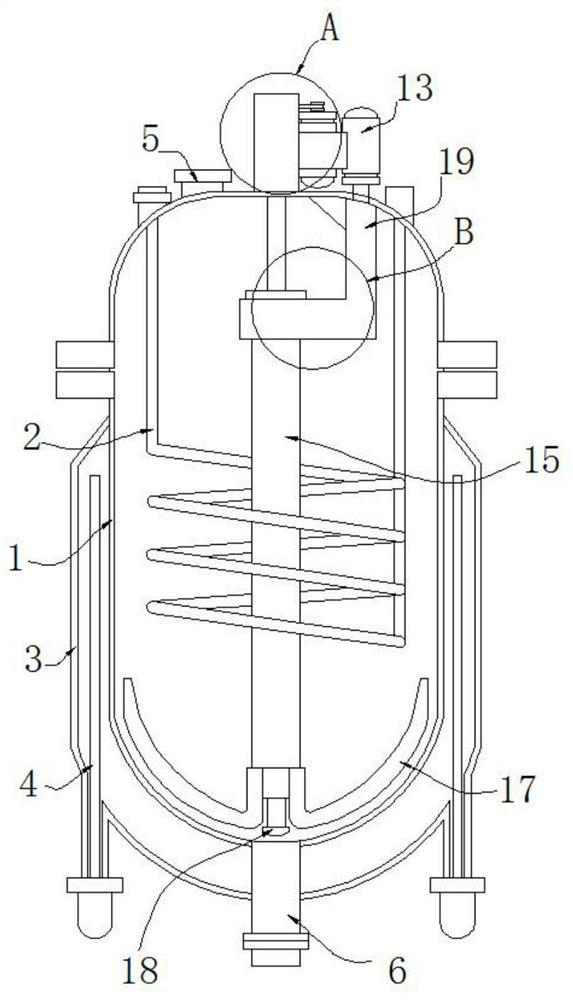

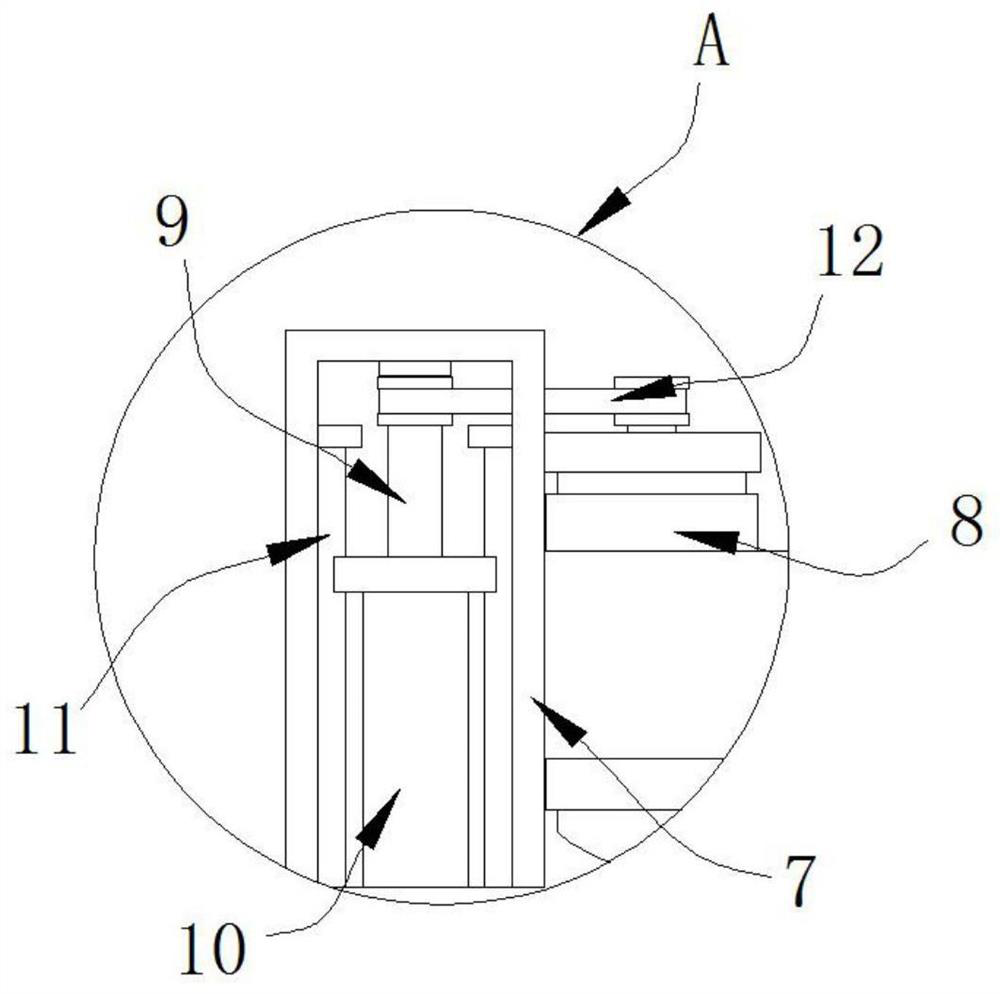

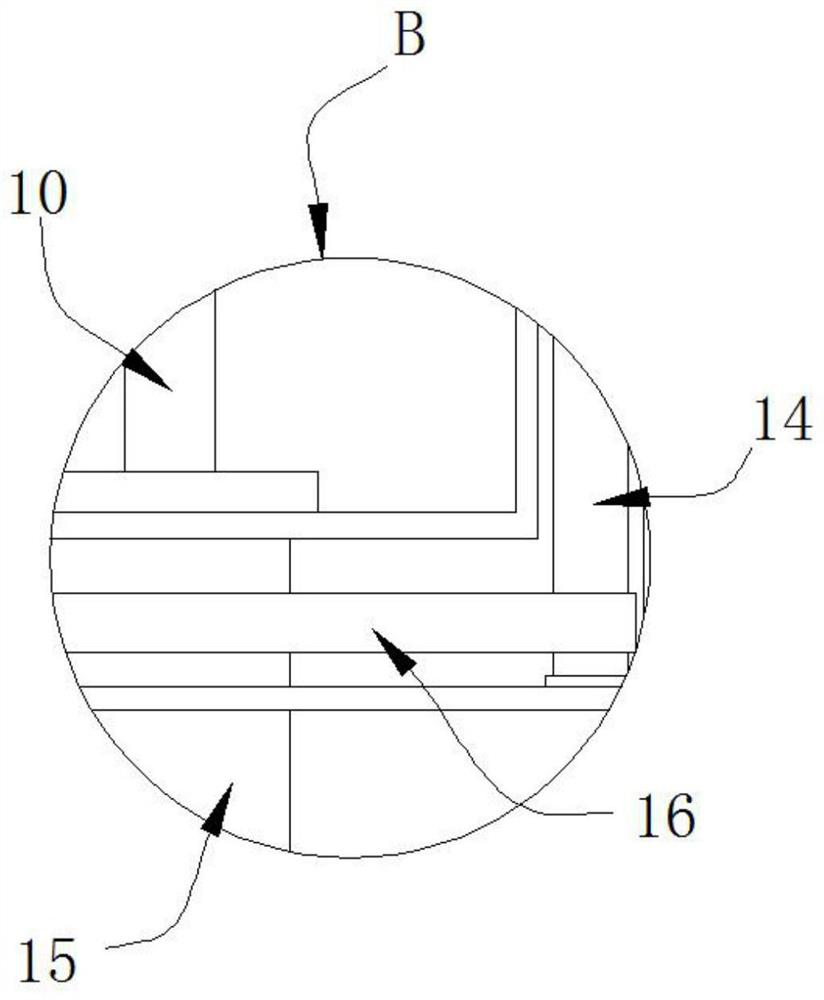

[0028] In the second embodiment, the top plate 7 is fixed with bolts on the top of the kettle body 1, and the rotating rod 9 connected to the top plate 7 is driven by the anti-blocking motor 8 to rotate, so that the rotating rod 9 drives the telescopic rod 10 connected by its external thread to penetrate Stirring rod 15, and expands and contracts outside the bottom end of stirring rod 15, utilizes the anti-blocking head 18 at the end of telescopic rod 10 to carry out dredging operation to discharge port 6, effectively prevents reactant sediment from clogging up the discharge port 6 of still body 1 problem, practicality is strong.

Embodiment 3

[0029] In the third embodiment, a heating jacket 3 is arranged outside the bottom of the kettle body 1, and an electric heating tube 4 is installed inside the heating jacket 3, and the temperature of the kettle body 1 can be increased by using the electric heating tube 4, and at the same time, it is coiled inside the kettle body 1 The inner cooling coil 2, and the two ends of the inner cooling coil 2 extend to the outside of the kettle body 1, and the function of rapidly cooling the reactants inside the kettle body 1 is realized by injecting cooling liquid into the inner cooling coil 2, the structure is simple and practical Strong.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com