A rotary yaw high speed axial flow stirring robot

A high-speed shaft and robot technology, applied in mixers, mixer accessories, mixers and other directions with a rotating mixing device, can solve the problems of uneven mixing and poor mixing effect of materials, and improve the mixing uniformity of materials. The effect of material stirring and mixing is sufficient and the driving efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

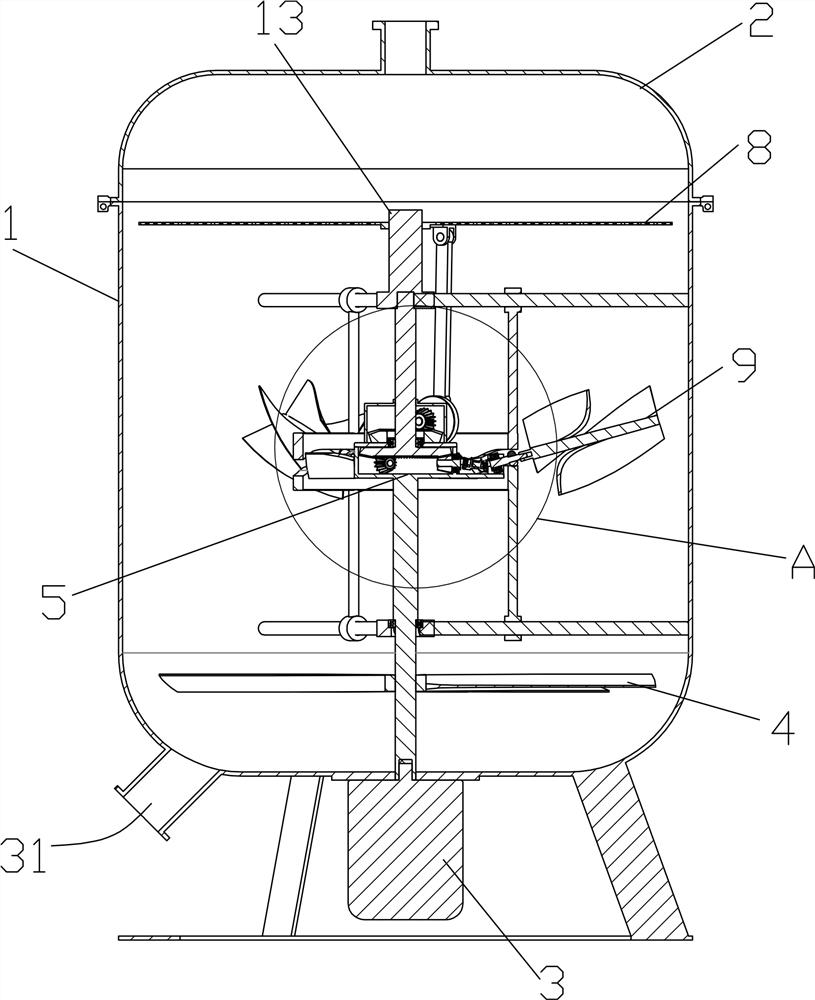

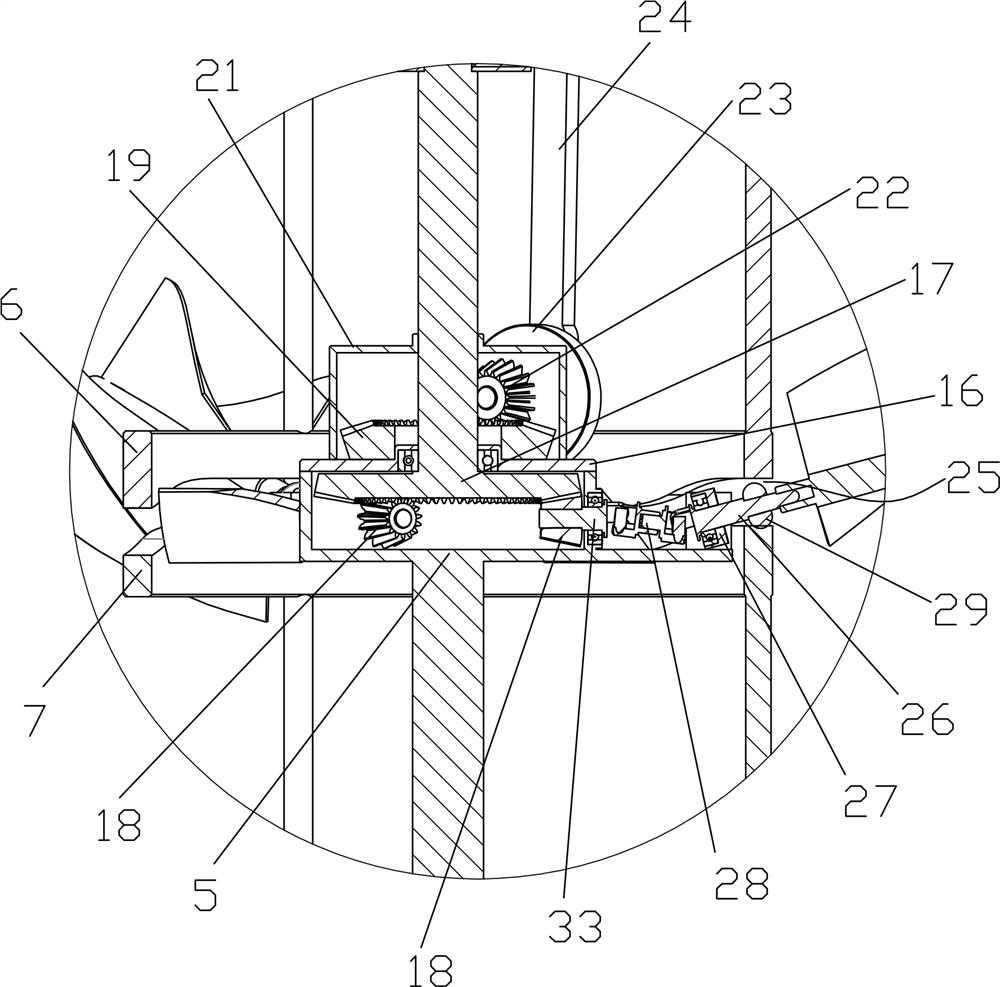

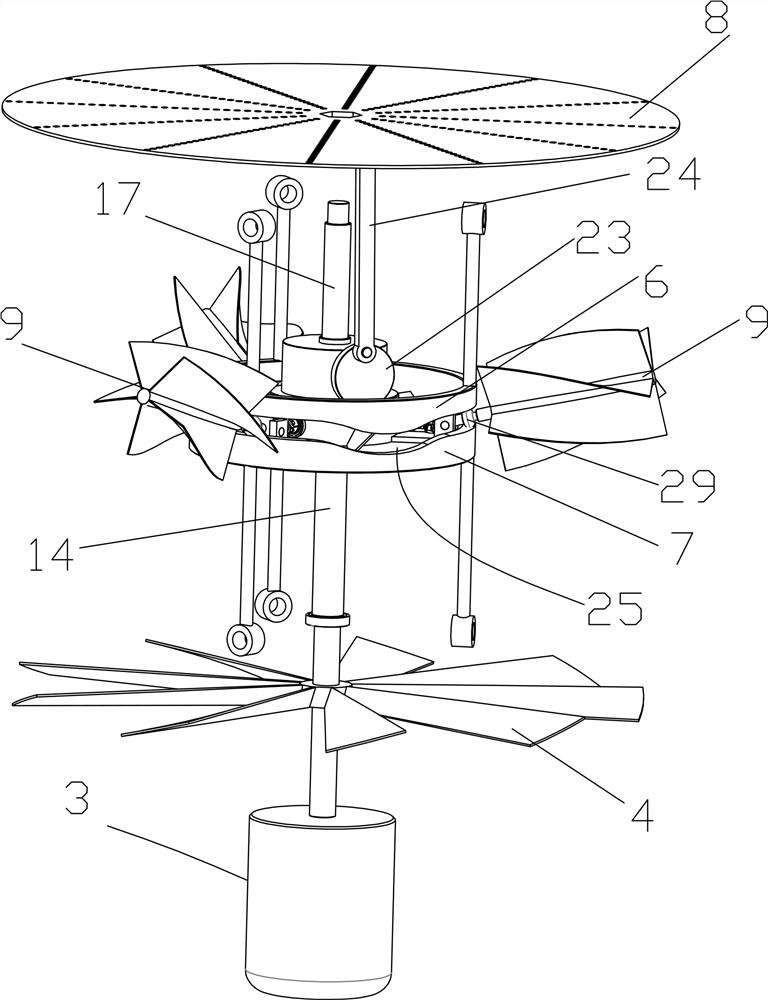

[0026] Such as Figure 1 to Figure 5 As shown, a rotary yaw high-speed axial-flow stirring robot described in this embodiment includes a stirring tank body 1, a stirring cover 2 detachably connected to the top of the stirring tank body 1, a driving motor 3, and an axial-flow stirring paddle 4 , rotating paddle seat 5, annular upper end face cam 6, annular lower end face cam 7, upper vibrating screen 8 and three deflection stirring paddles 9; There are two upper supporting frameworks 11 and lower supporting frameworks 12 that are center-radiating. The center of the upper supporting framework 11 extends upward with a guide post 13; the drive motor 3 is fixed on the bottom of the stirring tank 1, and the The output end of the driving motor 3 extends into the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com