Method for supporting milling belt

A grinding and belt grinding technology, applied in grain processing, application, grain pod removal, etc., can solve the problem that the idler cannot provide uniform and continuous support, and achieve the effects of easy heat dissipation, uniform grinding pressure and low working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

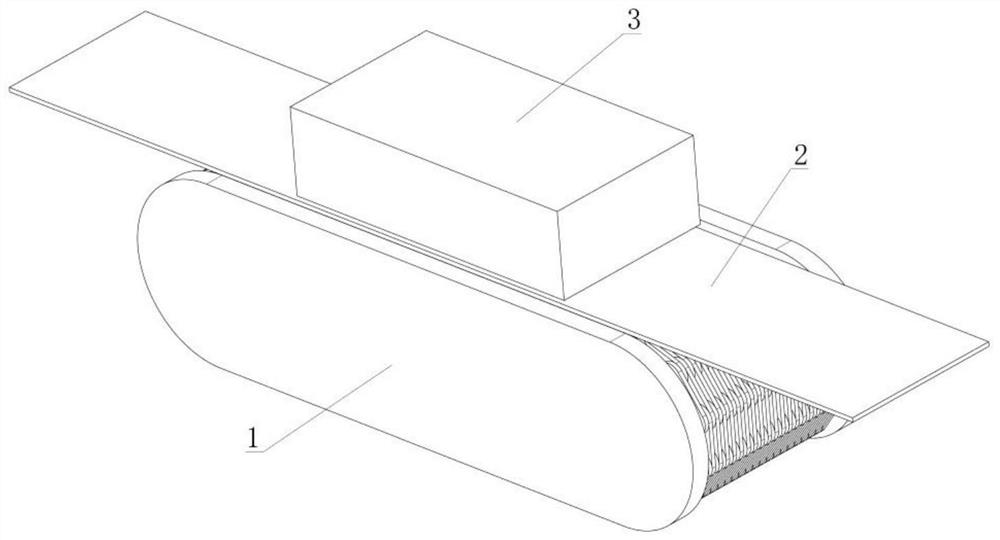

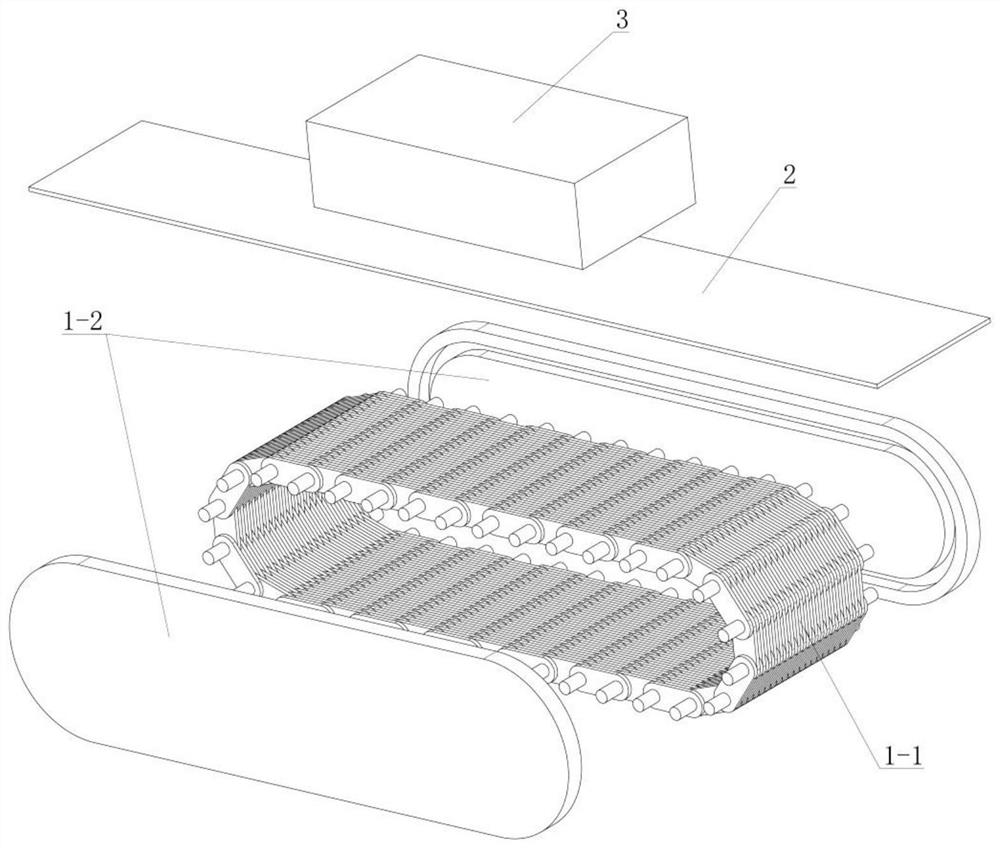

[0019] like figure 1 , figure 2 , this embodiment includes a support device 1 , a grinding belt 2 , and a mill 3 . The support device 1 includes a support chain 1-1 and a side plate 1-2.

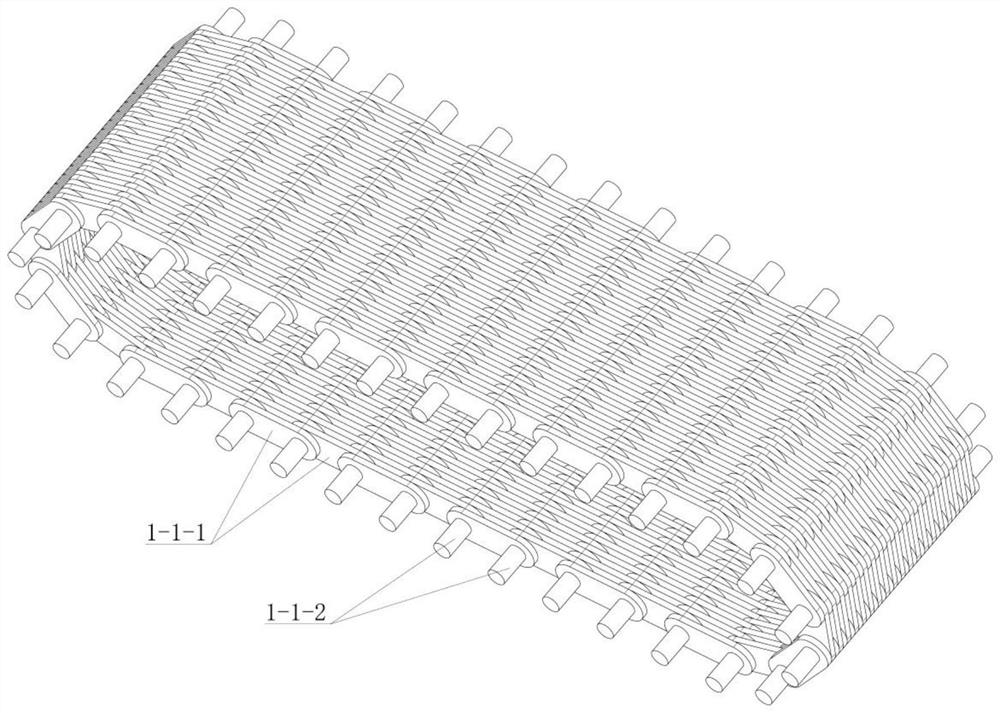

[0020] like image 3 , the support chain 1-1 includes a support chain plate 1-1-1 and a rod 1-1-2; the support chain plates 1-1-1 are connected by a rod 1-1-2.

[0021] like Figure 4 , Side plate 1-2 is provided with slideway 1-2-1.

[0022] like figure 1 , figure 2 , the rod 1-1-2 can slide along the slideway 1-2-1, the material is ground between the grinding belt 2 and the mill 3, and the supporting chain plate 1-1-1 is in the grinding area against the grinding belt 2 provides support. During the grinding process of the grinding belt 2, under the action of friction between the grinding belt 2 and the supporting chain plate 1-1-1, the supporting chain plate 1-1-1 and the grinding belt 2 move synchronously.

Embodiment approach 2

[0024] like Figure 5 , Image 6 , The side plate one 1-2 in the first embodiment is transformed into a side plate two 1-3, and the side plate two 1-3 has the same slideway as the side plate one 1-2. The sprocket 1-4 cooperates with the rod 1-1-2 to actively drive the supporting chain plate 1-1-1 to move synchronously relative to the grinding belt 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com