A self-identifying multi-angle magnetic pole head chemical magnetic particle grinding processing device

A technology of grinding processing and grinding device, applied in the field of polishing, can solve problems such as difficult processing of included angles, and achieve the effects of reducing manual operation, uniform grinding pressure and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

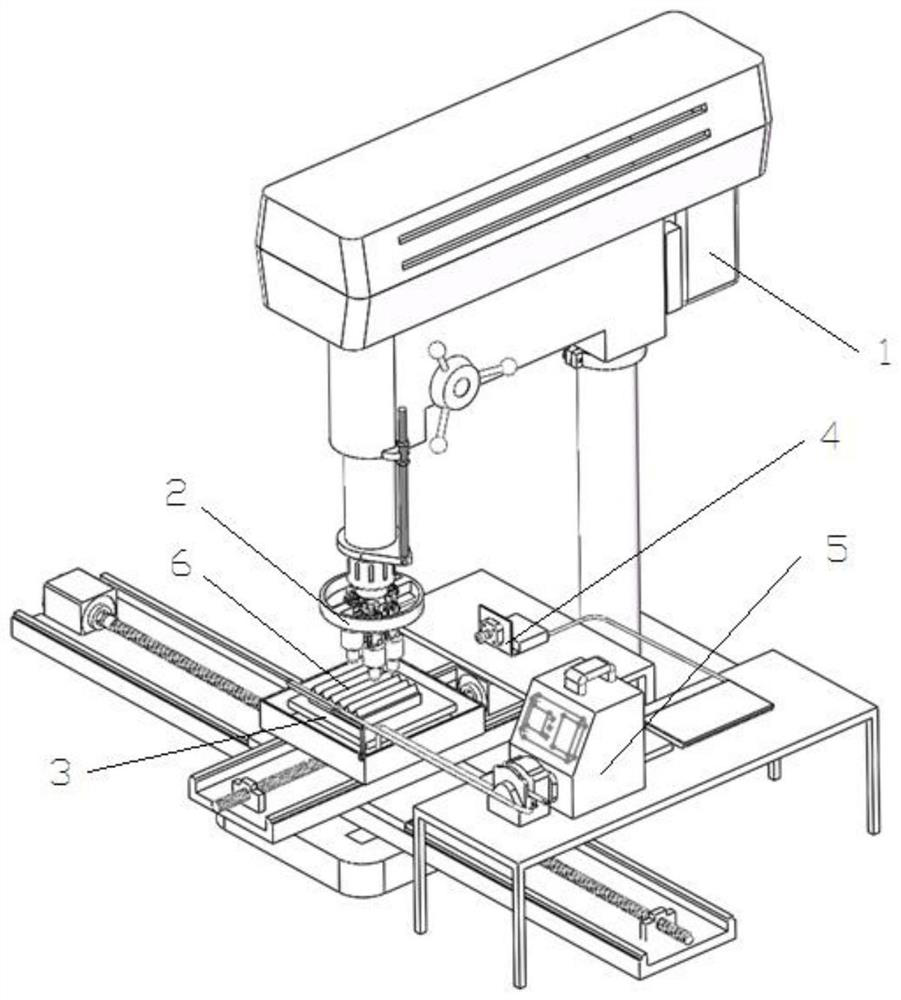

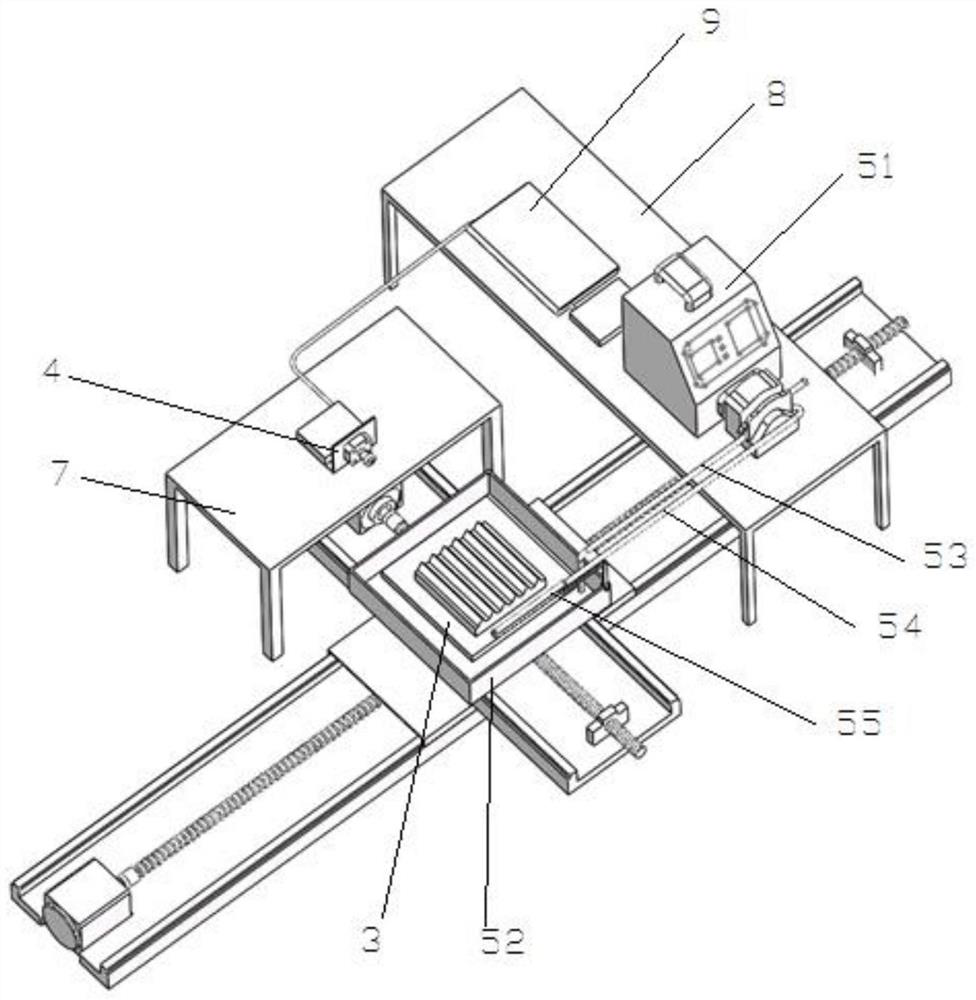

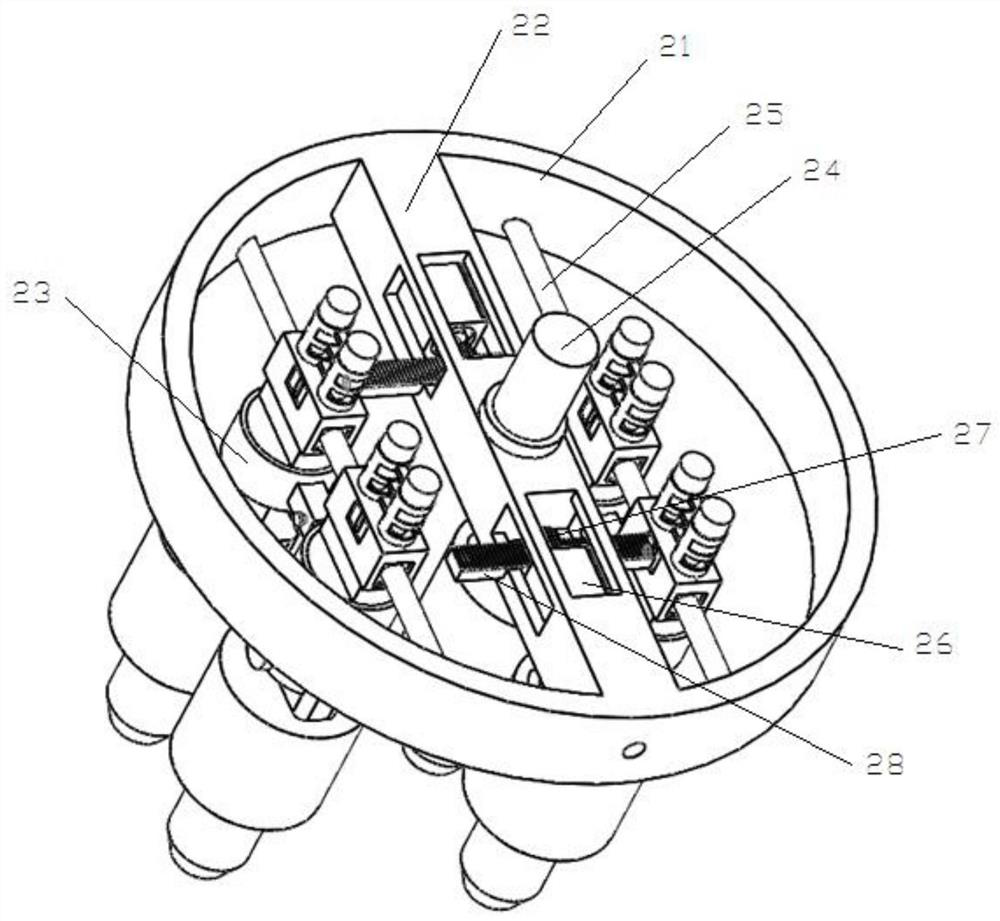

[0035] Such as Figure 1-Figure 8 , a self-identifying multi-angle magnetic pole head chemical magnetic particle grinding processing device, including a drilling machine tool 1, a magnetic particle grinding device 2 is provided on the main shaft of the drilling machine tool, and a workpiece 6 with a v-shaped groove is placed on a workbench 3, The camera 4 shoots the image of the workpiece and the computer recognizes the angle of the V-shaped groove, and transmits the calculation result to the magnetic particle grinding device 2 to adjust the angle accordingly. First, the chemical solution spraying device 5 sprays the chemical solution on the surface of the workpiece 6 to form a layer of dull chemical film, and then use the magnetic particle grinding process to simultaneously grind the two slopes of the V-shaped groove.

[0036] The camera 4 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com