Automobile door water cutting metal plate edge covering method and device

A technology for automobile doors and hemming devices, which is applied in the directions of transportation, packaging, vehicle parts, etc., can solve problems such as loosening, waves, and reduce production costs, and achieve the effects of eliminating springback, avoiding damage, and avoiding stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A water-cut sheet metal wrapping method for an automobile door, specifically comprising the following steps:

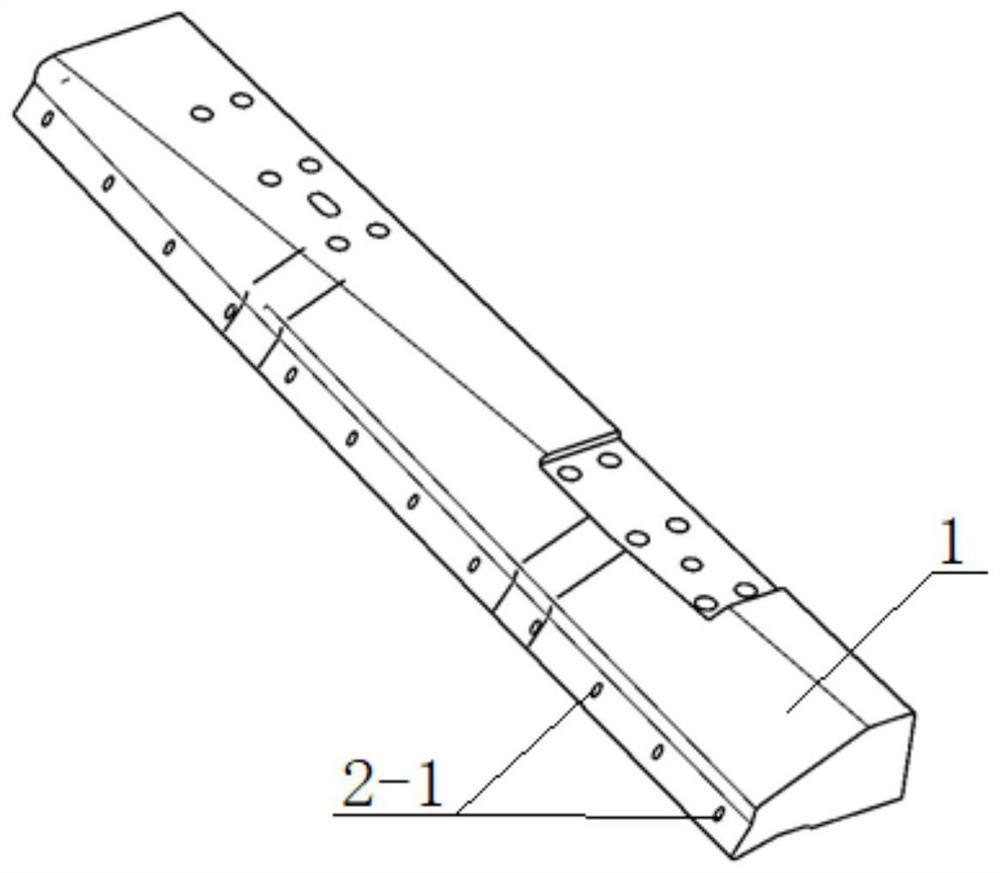

[0039] Step S1: Install and fix the water-cut edge sheet metal of the car door on the edge-wrapping mold;

[0040] Step S2: Under the action of external force, the water-cut edge sheet metal is flanged from the initial flanging angle α to 0° and the flanging process is completed, so that several smooth pits are formed on the outer surface of the water-cut edge sheet metal after bending.

[0041] A series of technical problems such as looseness, waves, burrs, noise and abnormal sound after hemming in the past are greatly reduced by setting a plurality of smooth dimples.

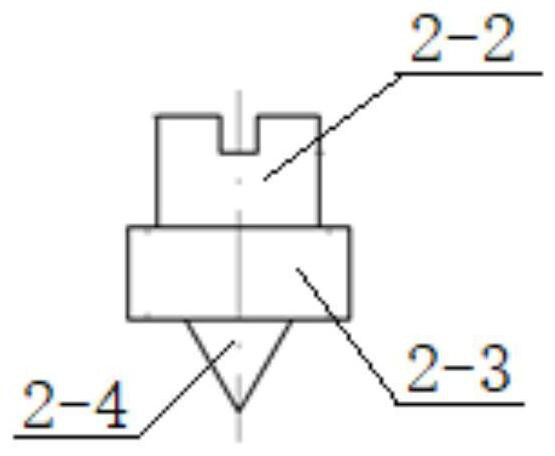

[0042] see figure 2 , in step S2, the flipping mechanism is used as an external force to complete the flanging process, and a number of protruding structures 2 are arranged on the flipping mechanism, and the protruding structures 2 are used to form smooth pits.

[0043] see Figure 4 and ...

Embodiment 2

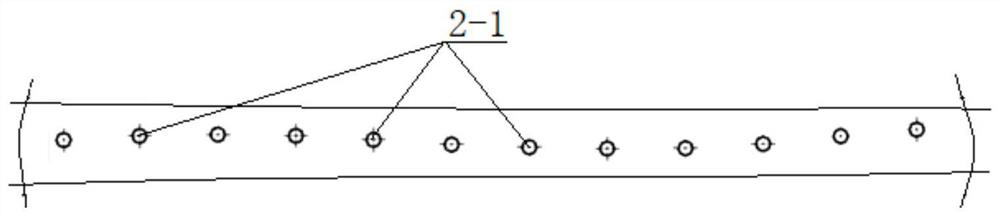

[0058] see Image 6 , Figure 7 and Figure 8 , in step S2, a single raised structure 2 is pressed down at one time to form three smooth dimples 2-12, and the three smooth dimples 2-12 are arranged in a circular array close to the center. Structurally, there are three cones distributed in a circular array around the center of the lower cylinder;

[0059] Which attached Figure 7 Among them, three smooth pits form a group, and several groups are arranged in a straight line, with Figure 8 Among them, three smooth pits form a group and are arranged in an "S" shape. Only a part of the "S" shape is drawn in the attached drawing for illustration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com