A grinding process for the inner wall of an oil-free vacuum pump cylinder

An oil-free vacuum pump and vacuum pump technology, applied in the direction of honing tools, grinding workpiece supports, manufacturing tools, etc., can solve the problems of shaking or swinging of the cylinder liner, difficulty in fixing the cylinder liner, and affecting the quality of grinding, so as to increase the fixing effect and improve the quality of grinding. Processing accuracy, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

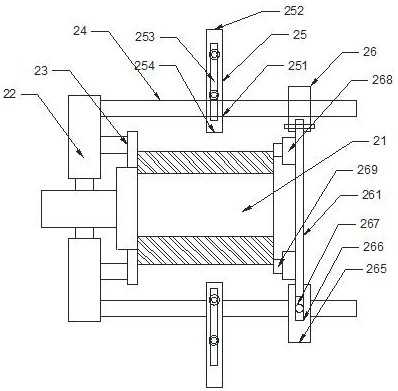

[0028] The invention provides a grinding process for the inner wall of an oil-free vacuum pump cylinder. The grinding process is completed by using a fixed tool for rough grinding and a grinding tool for fine honing.

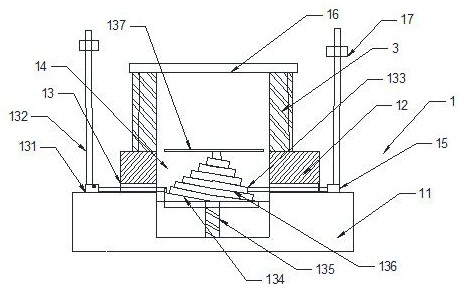

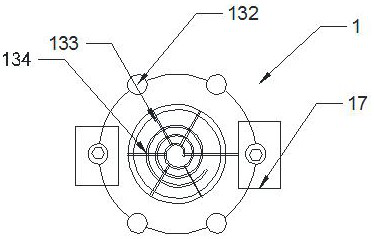

[0029] like Figure 1-2 As shown, in the present application, the fixing tool 1 for the oil-free vacuum pump cylinder includes a workbench 11, and the workbench 11 is provided with a round table base 12 for placing the pump body 3, and the outer ring of the pump body 3 is provided with irregular The inner ring is circular. Six symmetrical movable clamping slots 13 are formed on the circumferential end surface of the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com