Shot blasting machine for processing steel coil

A technology of shot blasting machine and steel coil, which is applied in the field of shot blasting treatment of the surface of the subsequent steel coil of the shot blasting machine and hot-rolled coil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

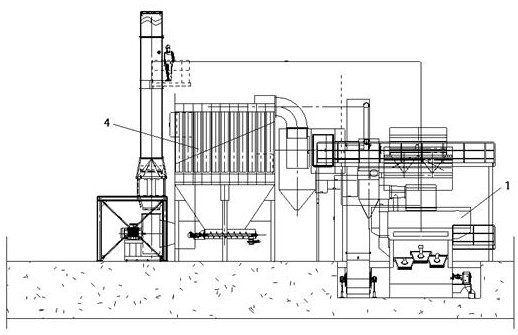

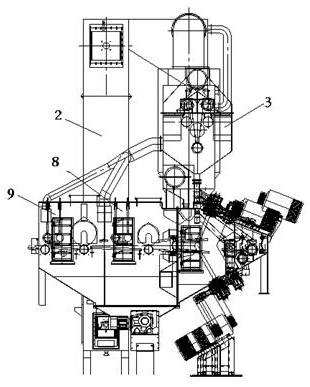

[0027] figure 1 As shown, the present invention is made up of shot blasting chamber 1, hoist 2, separator 3, dust removal equipment 4.

[0028] The elevator 2 is arranged beside the shot blasting chamber and on the exit side of the recovery chamber of the shot blasting chamber, and the exit of the recovery chamber of the shot blasting chamber is connected to the lower part of the elevator through a butt joint flange.

[0029] The separator is arranged above the shot blasting chamber and on the outlet side of the upper part of the elevator, and the upper outlet of the elevator is connected to the inlet of the separator through a butt flange. The separator is connected with the blasting head of the shot blasting chamber through the lower sand pipe.

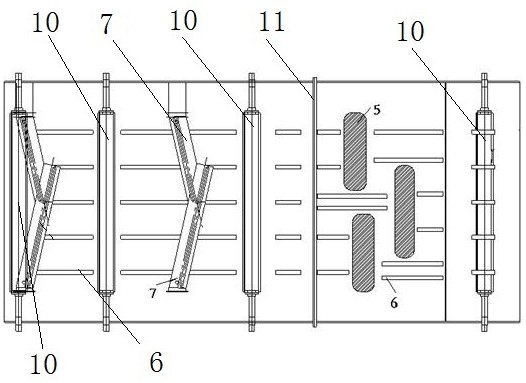

[0030] The dust removal equipment is located next to the hoist, and the dust removal equipment is connected to the shot blasting chamber, hoist, and separator through dust removal pipes. The belt threading guide 6 is installed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com