Multifunctional sole

A multi-functional, shoe sole technology, applied in shoe soles, footwear, applications, etc., can solve the problems of cumbersome production process, insufficient structural strength, and high overall cost, and achieve the effect of low processing cost and material cost, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

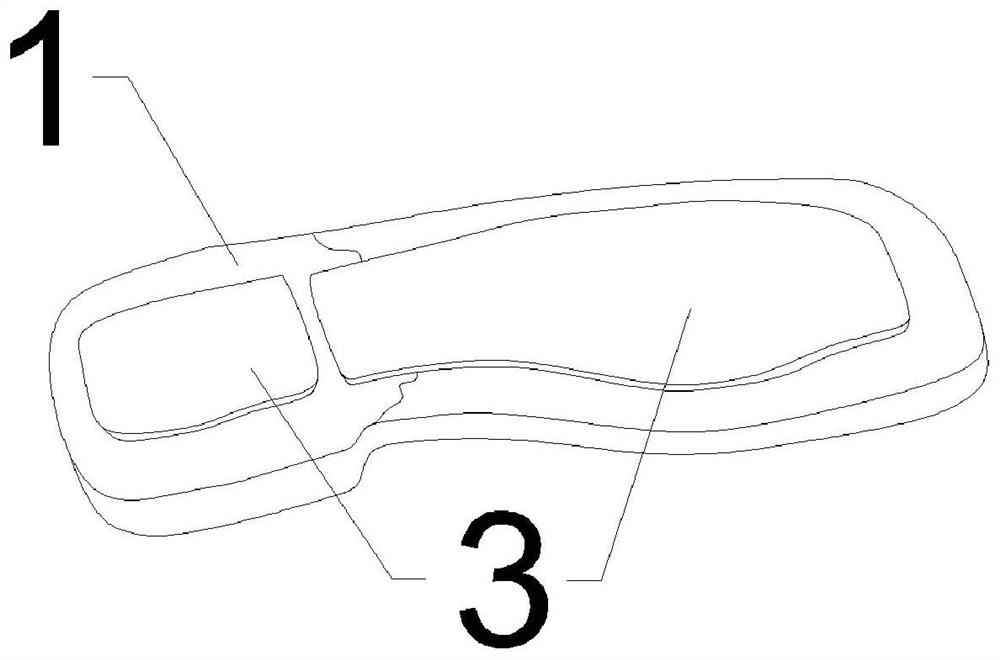

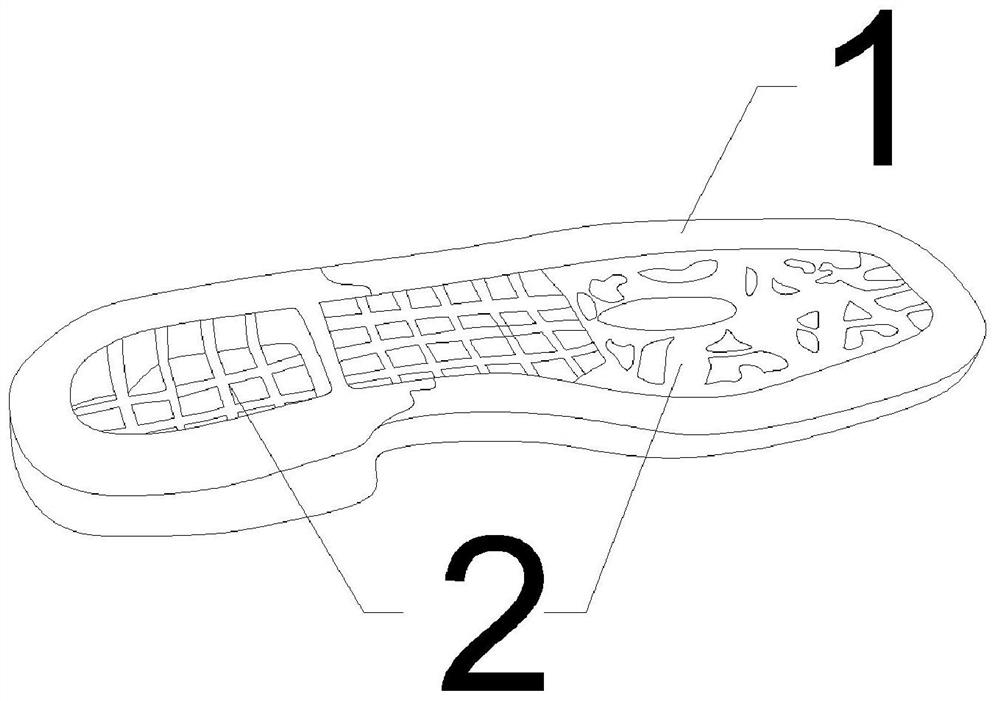

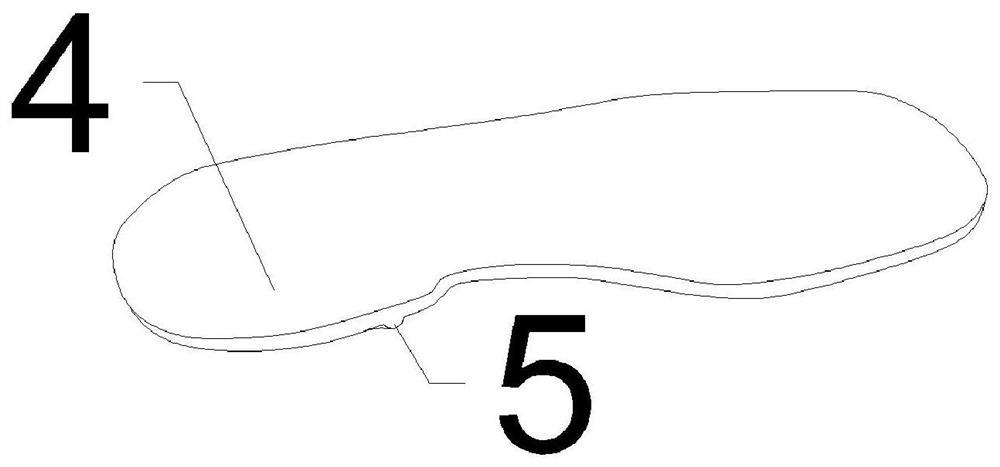

[0031] A kind of multifunctional shoe sole, comprises outsole 1 and midsole 4, and midsole 4 is arranged on the upper layer of outsole 1. The four edges of the midsole 4 are provided with connecting parts 7, the edge parts of the connecting part 7 are made of rubber material, and the main part is made of soft material with ductility. The midsole 4 is connected to the outsole 1 by thermal pressing or bonding through the edge portion of the connecting portion 7 . The outsole 1 and the midsole 4 form a special structure, and there is room for movement inside, but it will not affect the overall use of the sole.

[0032] Outsole 1 adopts the material of normal production, such as natural rubber or artificial synthetic rubber. The top surface of the outsole 1 is provided with two installation grooves 2, and the two installation grooves 2 are respectively opened on the front palm end and the heel end of the outsole 1, and the specific shape and frame size are all matched with the sh...

Embodiment 2

[0037] A kind of multifunctional shoe sole, comprises outsole 1 and midsole 4, and midsole 4 is arranged on the upper layer of outsole 1. The four edges of the midsole 4 are provided with connecting parts 7, the edge parts of the connecting part 7 are made of rubber material, and the main part is made of soft material with ductility. The midsole 4 is connected to the outsole 1 by thermal pressing or bonding through the edge portion of the connecting portion 7 . The outsole 1 and the midsole 4 form a special structure, and there is room for movement inside, but it will not affect the overall use of the sole.

[0038] Outsole 1 adopts the material of normal production, such as natural rubber or artificial synthetic rubber. The top surface of the outsole 1 is provided with two installation grooves 2, and the two installation grooves 2 are respectively opened on the front palm end and the heel end of the outsole 1, and the specific shape and frame size are all matched with the sh...

Embodiment 3

[0043] A kind of multifunctional shoe sole, comprises outsole 1 and midsole 4, and midsole 4 is arranged on the upper layer of outsole 1. The four edges of the midsole 4 are provided with connecting parts 7, the edge parts of the connecting part 7 are made of rubber material, and the main part is made of soft material with ductility. The midsole 4 is connected to the outsole 1 by thermal pressing or bonding through the edge portion of the connecting portion 7 . The outsole 1 and the midsole 4 form a special structure, and there is room for movement inside, but it will not affect the overall use of the sole.

[0044] Outsole 1 adopts the material of normal production, such as natural rubber or artificial synthetic rubber. The top surface of the outsole 1 is provided with two installation grooves 2, and the two installation grooves 2 are respectively opened on the front palm end and the heel end of the outsole 1, and the specific shape and frame size are all matched with the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com