Bread maker with steaming function

A bread machine and steaming technology, which is used in toaster devices, kitchen utensils, home utensils, etc., can solve the problems of scorching, inability to mix bread materials, affecting user experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

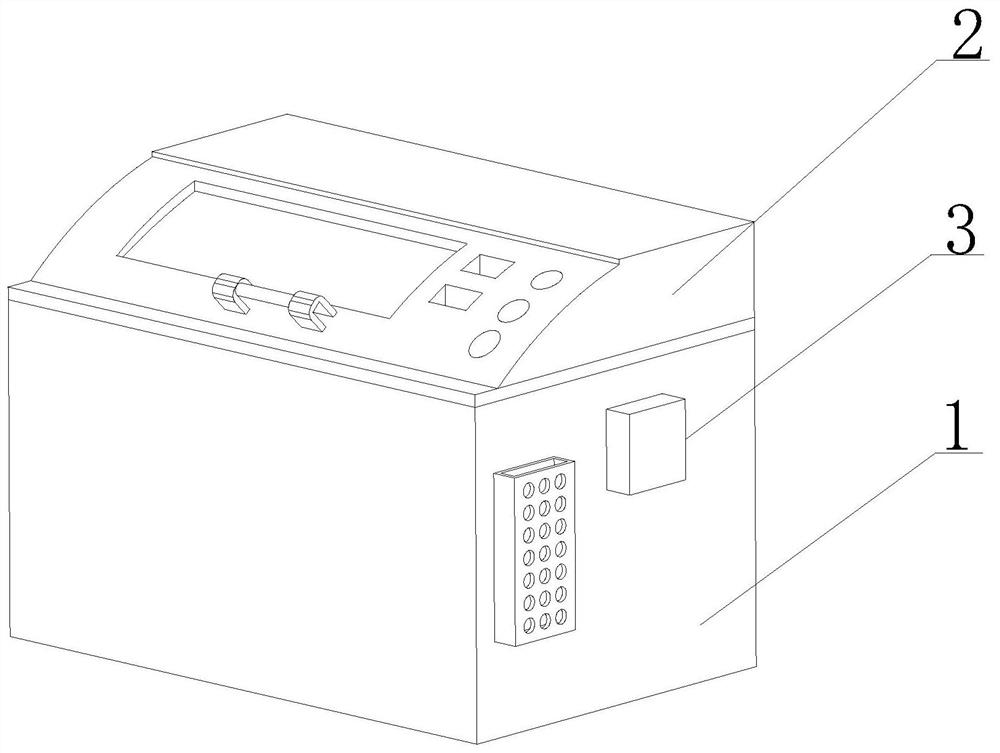

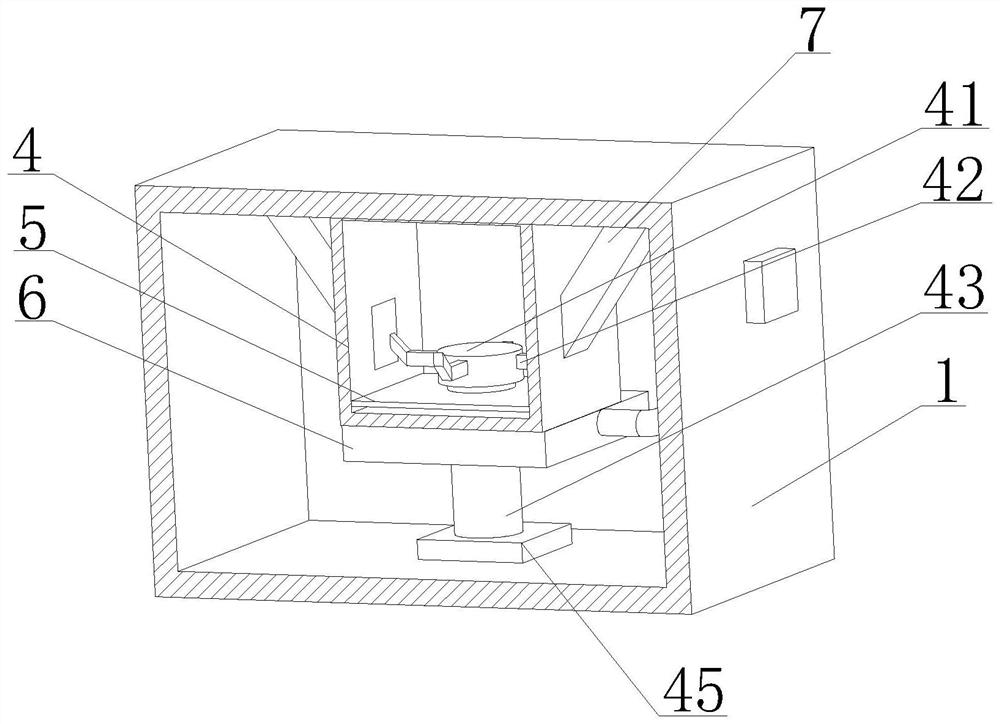

[0039] like figure 1 - Image 6As shown, the present invention provides a bread machine with a steaming function, including a bread machine main body 1, a top cover plate 2 is movably connected to the bread machine main body 1, and a water inlet 3 is fixedly connected to the right end of the bread machine main body 1. The upper end of the main body 1 is provided with a control element, which can be used to control the time of the bread machine. In addition, an acrylic plate is arranged on the bread machine, and the working process inside the bread machine can be viewed from the outside. The internal setting of the main body 1 of the bread machine There is a stirring box 4, and the inner bottom end of the bread machine main body 1 is fixedly connected with a driving motor 45, and the upper end of the driving motor 45 is provided with a driving shaft 43, and the upper end of the driving shaft 43 extends to the inside of the mixing box 4, and the driving shaft 43 A stirring shaf...

Embodiment 2

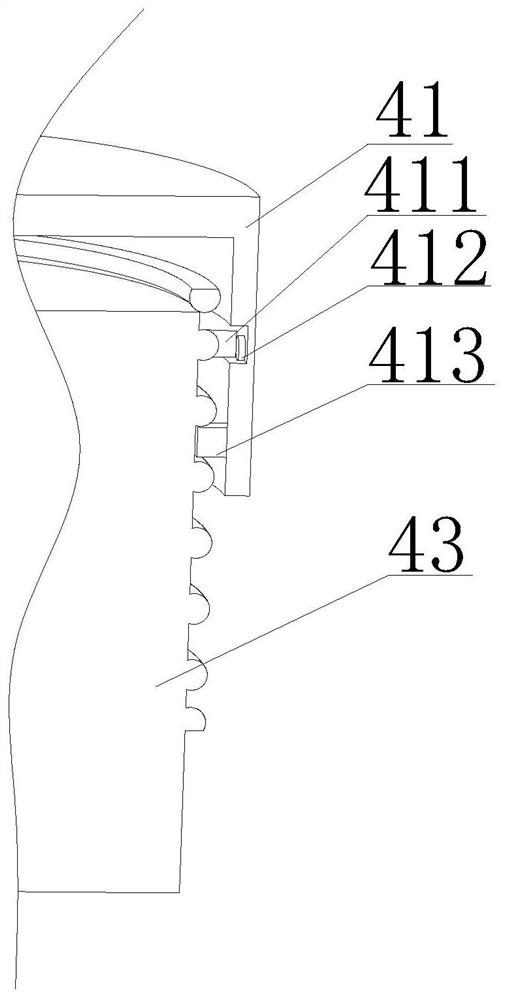

[0042] like Figure 2-6 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: the outer wall of stirring shaft 41 is fixedly connected with stirring element 42, and the setting of stirring shaft 41 and stirring element 42, thereby facilitates the bread material in stirring Mixing, to avoid adding condiments at one time, causing condiments to form agglomerates, causing damage to the dough, the inner wall of the stirring shaft 41 is fixedly connected with a slider 413, and the combination of the stirring shaft 41, the driving shaft 43 and the sliding block 413 is set, It can be realized that when the driving shaft 43 rotates, the resistance of the external bread dough is getting bigger and bigger, so that the stirring shaft 41 is lowered along the driving shaft 43, thereby compressing the support plate 5, and then the stirring box is moved according to the pressure of extrusion. 4. The steam transmission element 44 provided at the bottom...

Embodiment 3

[0045] like Figure 1-6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: preferably, the inside of the mixing box 4 is provided with a slide plate 5, the inside of the slide plate 5 is provided with a circular slot 51, and the steam transmission There are multiple elements 44, which are evenly distributed on the upper end of the slide plate 5, and the upper end of the steam transmission element 44 has a circular slot 51 corresponding to the society, so as to facilitate the steaming of the bread material. The middle part of the slide plate 5 is provided with a through hole, and It is compatible with the outer wall of the drive shaft 43, so that the stirring shaft 41 can push the slide plate 5 to slide downwards, and according to the setting of the rotating element 52 and the right arc cover plate 53, the support screw 54 can be pushed to separate from the support plate 56, thereby The steam transfer element 44 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com