Gypsum crushing equipment for orthopedic nursing

A technology of crushing equipment and gypsum, which is applied in the direction of grain processing, etc., can solve problems such as failure to set up, endanger health, pollute the environment, etc., and achieve the effect of ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

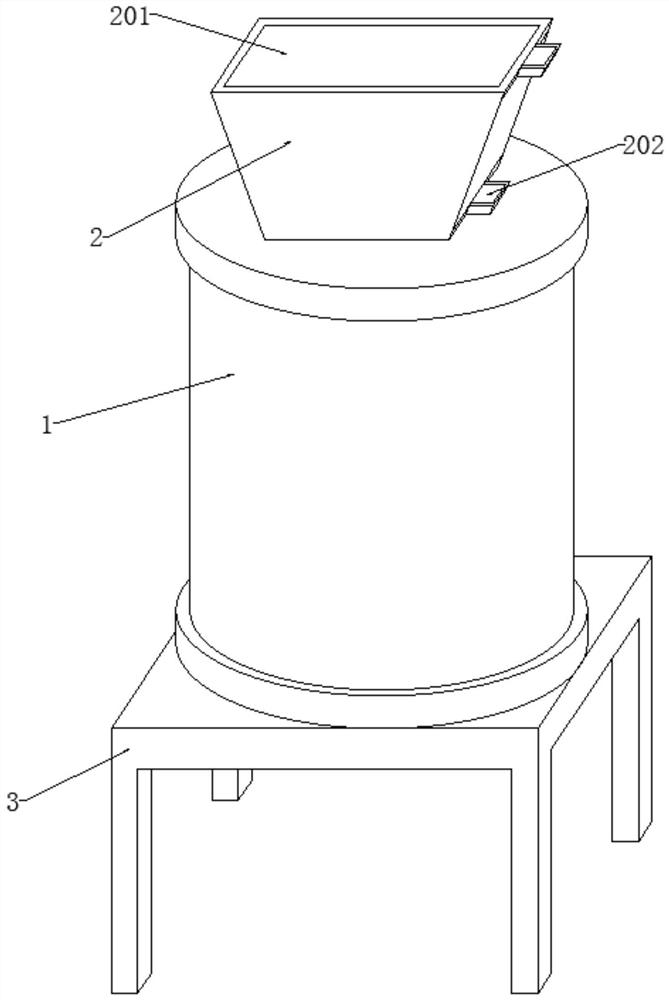

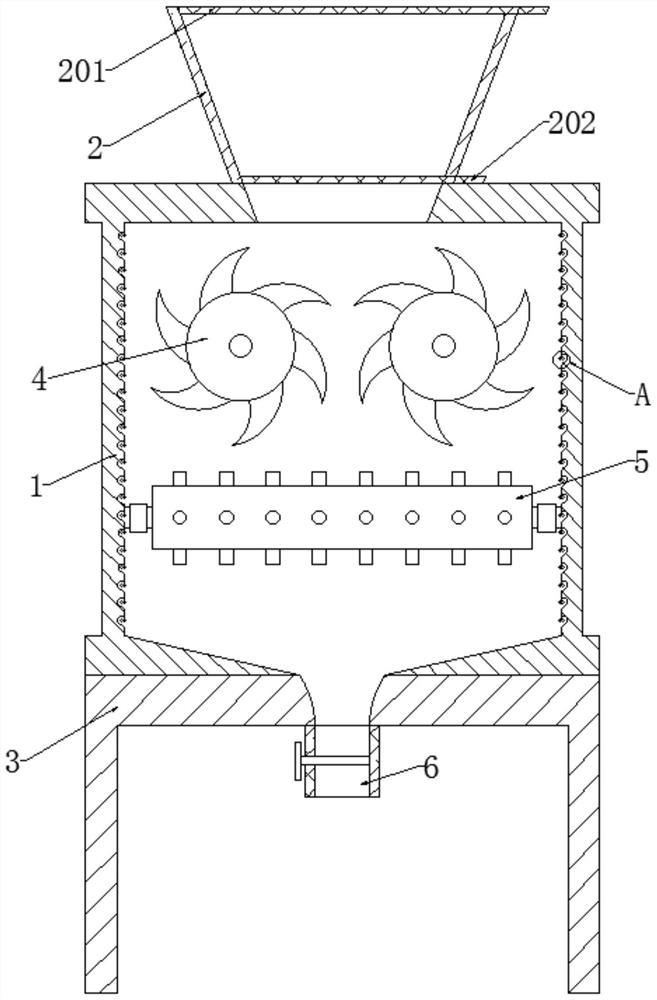

[0031] see Figure 1-Figure 4 , in an embodiment of the present invention, a gypsum crushing equipment for orthopedic care, including a working bucket 1, a lower hopper 2, a cover 201, a lower material slide 202, a support 3, a crushing device 4, a grinding device 5 and a discharge pipe 6, The inner wall of the working barrel 1 is arranged vertically and vertically in equal rows, surrounding and movingly installed with several ash control components 7 capable of humidifying dust;

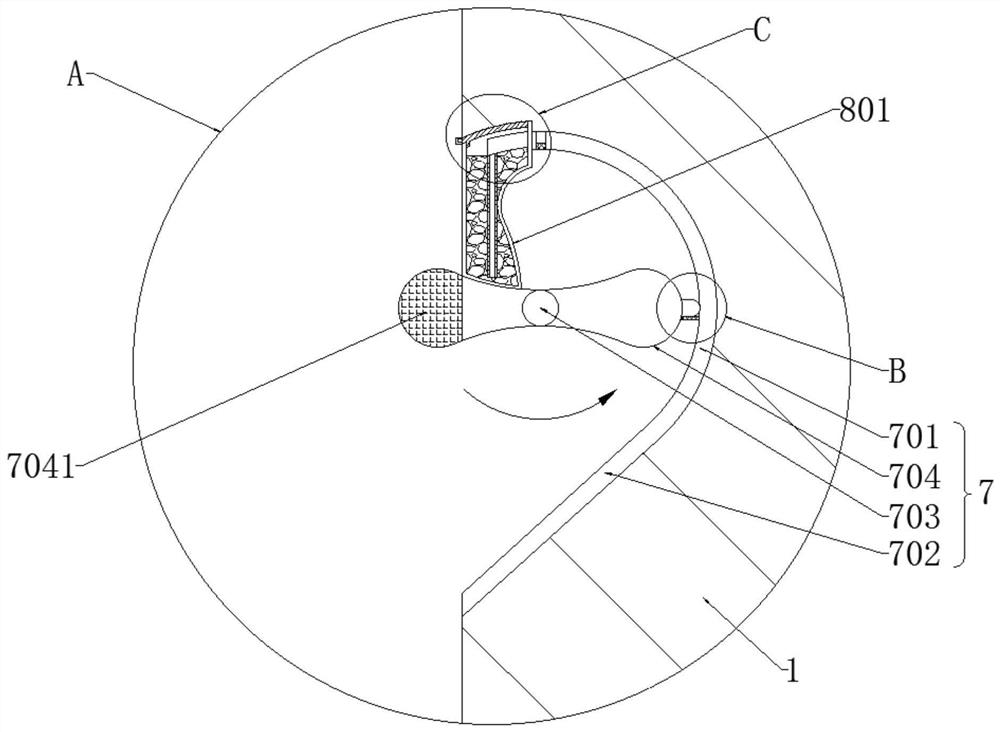

[0032] The ash control components 7 are respectively composed of an arc 701 , a straight path 702 , a rotating shaft 703 and a balance plate 704 .

[0033] In the embodiment of the present invention, both the arc 701 and the straight 702 are fixedly installed on the inner wall surface of the working barrel 1 and both of them jointly divide the inner wall of the working barrel 1 into a cavity, and the inside of the arc 701 and the straight 702 are both hollow , the arc 701 and the straight 702 are r...

Embodiment 2

[0038] see image 3 , Figure 5 and Figure 6 , in the embodiment of the present invention, the position of the left end of the top side outer surface of the balance plate 704 is fixedly installed on the inner wall of the working bucket 1 with several water control components 8, and the water control components 8 are respectively composed of a water storage tank 801, a clear water 802, a suction pipe 803 and baffle 804 constitute, so that by siphon outward water.

[0039] In the embodiment of the present invention, the water storage tanks 801 are all fixedly installed on the inner wall of the working barrel 1 and are all located above the left end of the balance plate 704. The insides of the water storage tanks 801 are filled with clean water 802, and the tops of the arcs 701 run through To the inner top position of the water storage tank 801 and through the installed suction pipe 803, the bottom and tail of the suction pipe 803 all extend to the inner bottom end position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com