Welding device and welding method for single-side welded dense-grid solar cell string

A solar cell, single-sided welding technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of not developing corresponding ones, and achieve the effect of simplifying the control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Combine below Figure 1 to Figure 10 Specific embodiments of the present invention will be described.

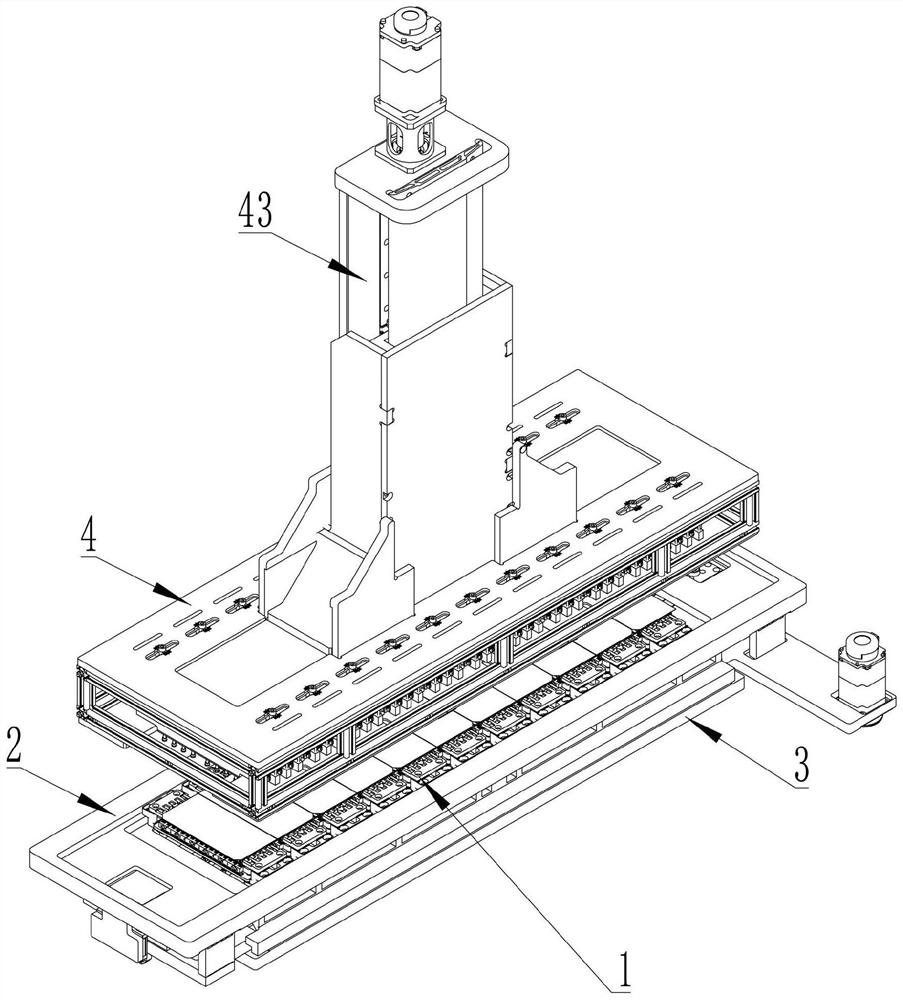

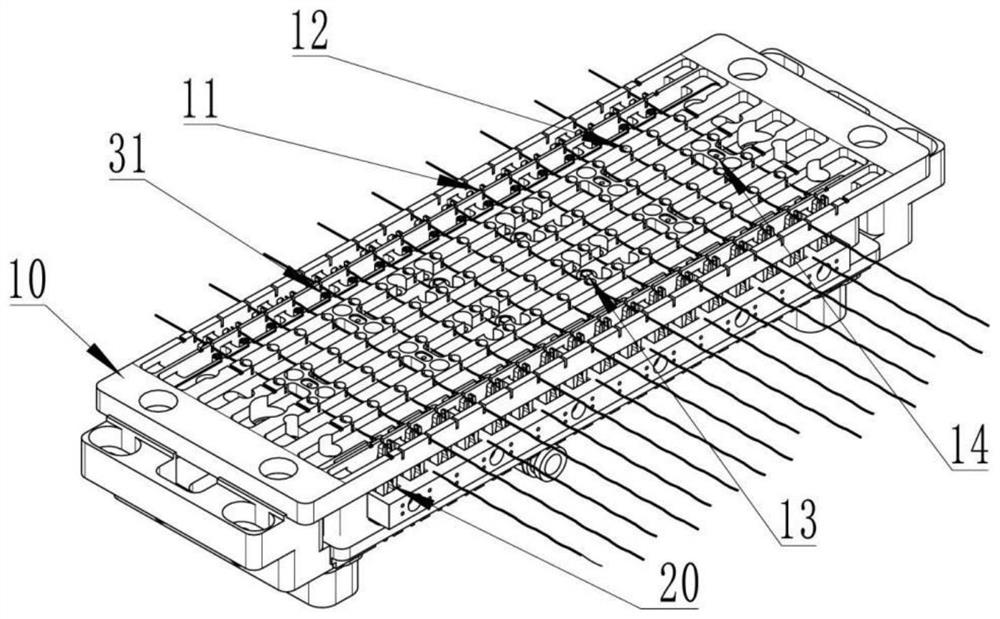

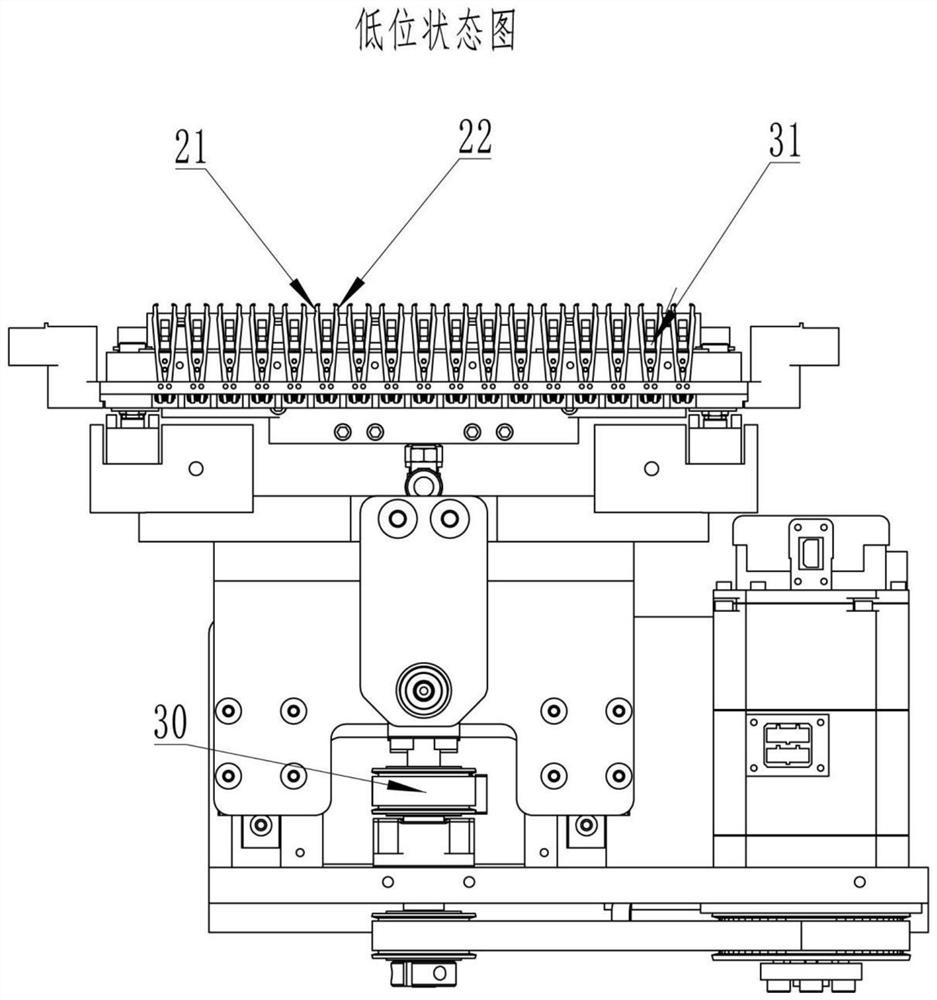

[0035] figure 1 and figure 2 It shows the overall layout of the welding device and the composition of the welding station. Taking the welding of a single-sided dense grid cell string composed of 11 cells with 17 grids as an example, the welding device includes: The welding station 1 of the battery sheet is used to fix the receiving station 2 of the welding station 1, the base 3 for installing the receiving station, and the welding head assembly 4 that moves up and down above the welding station 1; wherein, the welding station 1 is provided with several The guide grooves 11 for accommodating welding ribbons arranged along the length direction of each grid line of the battery sheet, the welding ribbons are placed in the welding ribbon guide grooves 11, and the battery sheets are placed above the welding ribbons.

[0036] The welding station is composed of 11 welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com