Intelligent machine tool with combination of drilling and tapping

An intelligent machine tool, drilling and tapping technology, applied in the direction of metal processing machinery parts, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of affecting the machining accuracy of the workpiece, affecting the yield of the workpiece, reducing the work efficiency, etc., to avoid offset Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following description serves to disclose the invention to enable those skilled in the art to practice the invention. The preferred embodiments described below are given by way of example only, and other obvious modifications will occur to those skilled in the art.

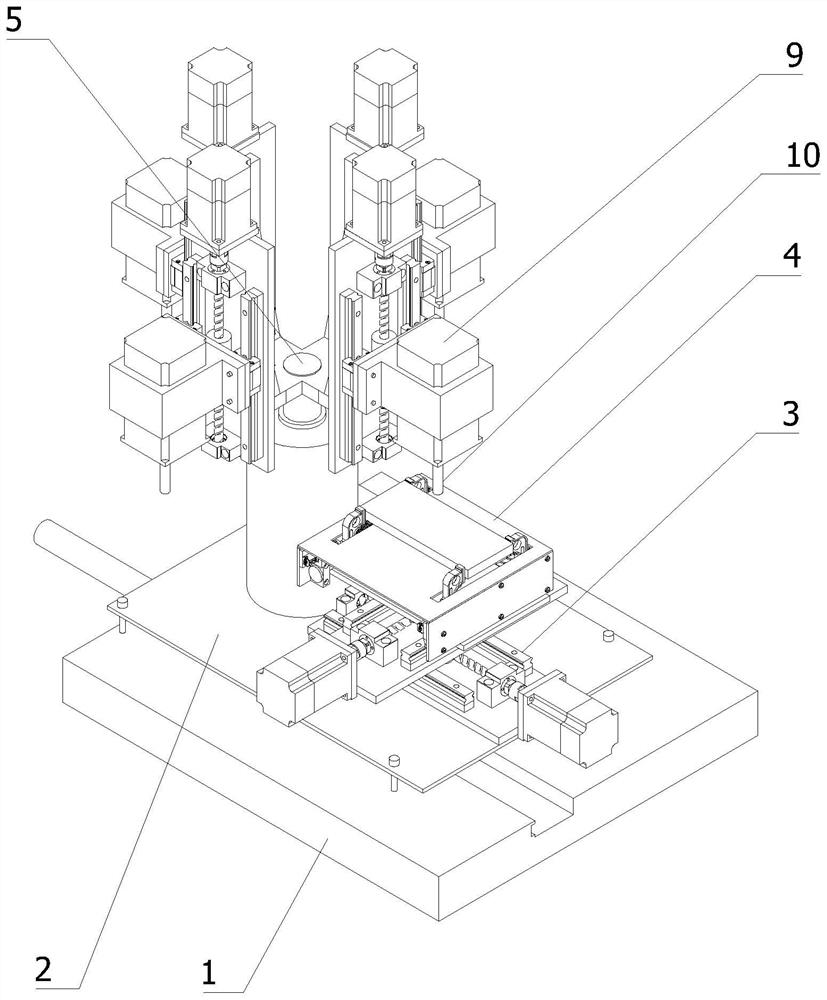

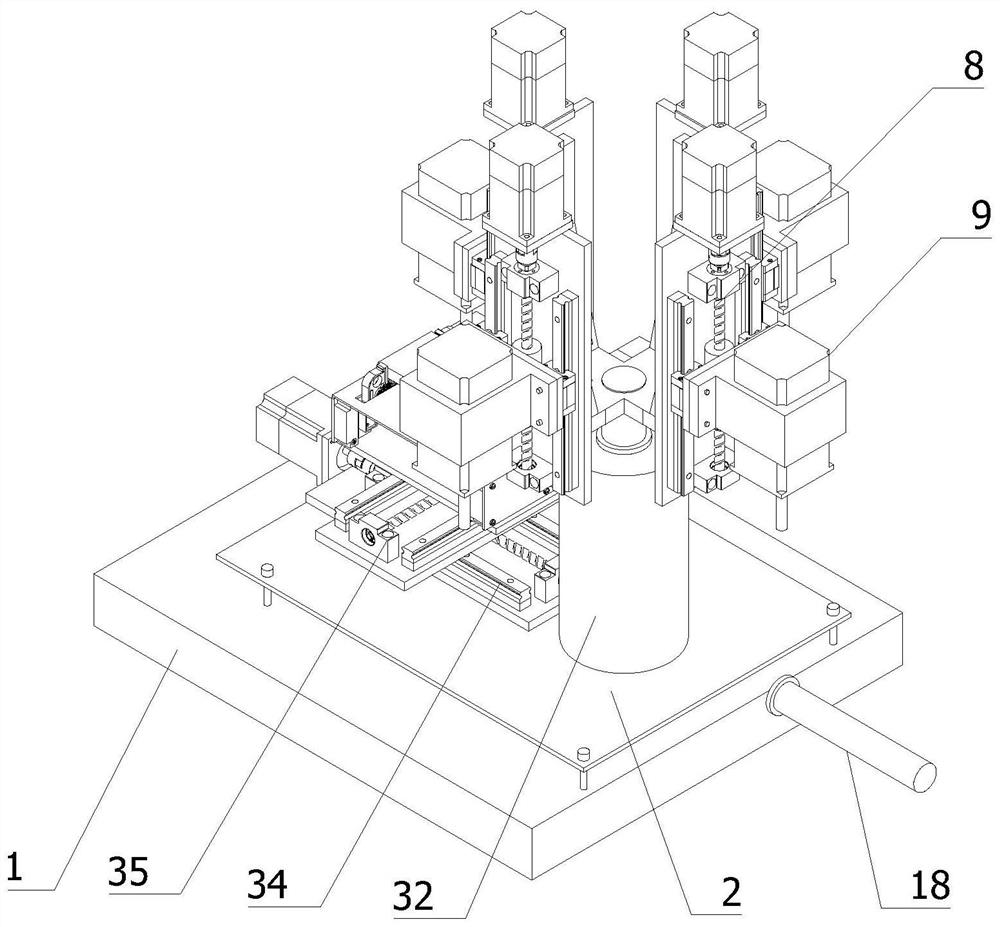

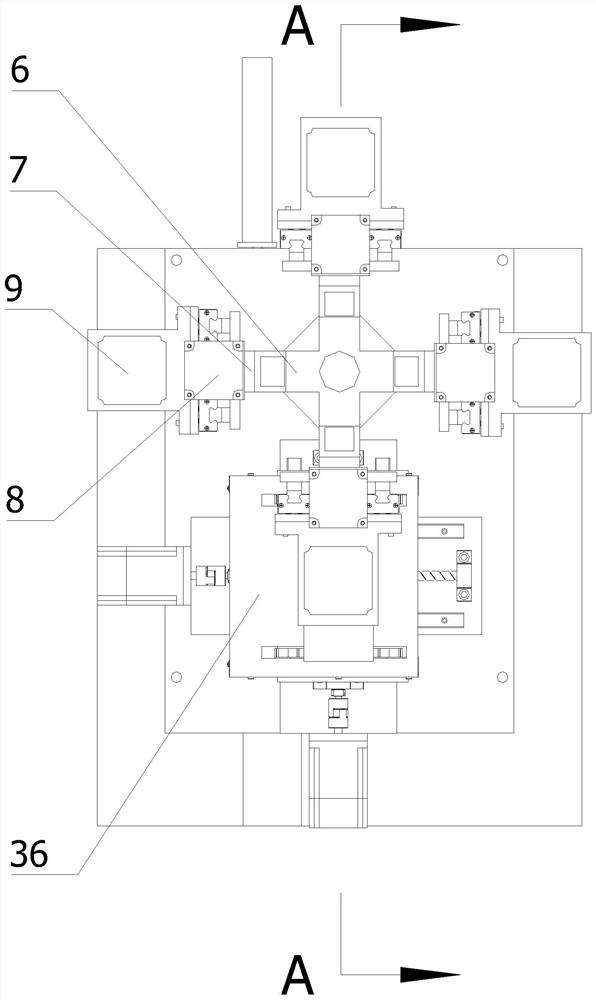

[0047] In order to solve the technical problem of how to automatically replace different types of drills 10 on the same machine tool, such as Figure 1 to Figure 4 As shown, the following technical solutions are provided:

[0048] A drilling-tapping combined intelligent machine tool, comprising:

[0049] base 1;

[0050] The workbench 2 is horizontally erected on the top of the base 1;

[0051] The XY axis drive mechanism 3 is arranged on the worktable 2;

[0052] The positioning fixture 4 is arranged on the working end of the XY axis drive mechanism 3;

[0053] It also includes a rotating shaft 5. The rotating shaft 5 is vertically and rotatably inserted on the side of the worktable 2 away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com