Manufacturing technology of aluminum alloy transfer printing silica gel heads

A manufacturing process, aluminum alloy technology, applied in the field of hardware, can solve problems such as low efficiency and difficulty in ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

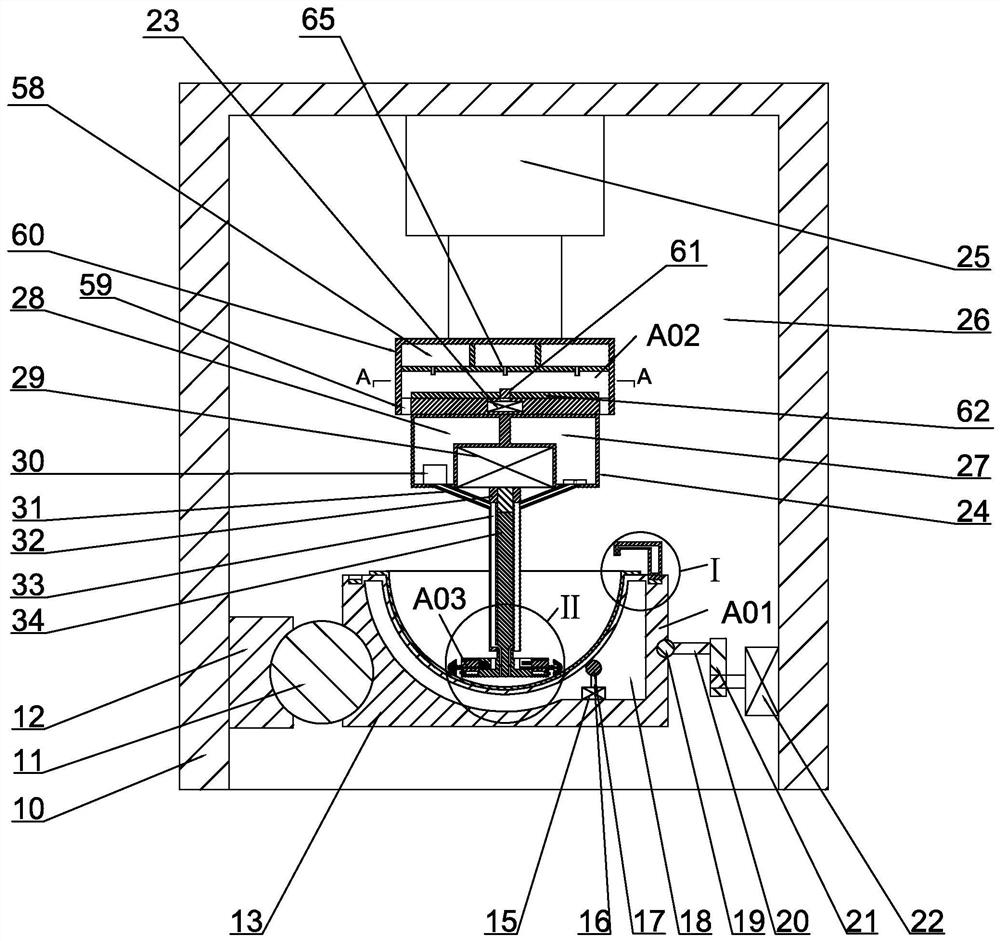

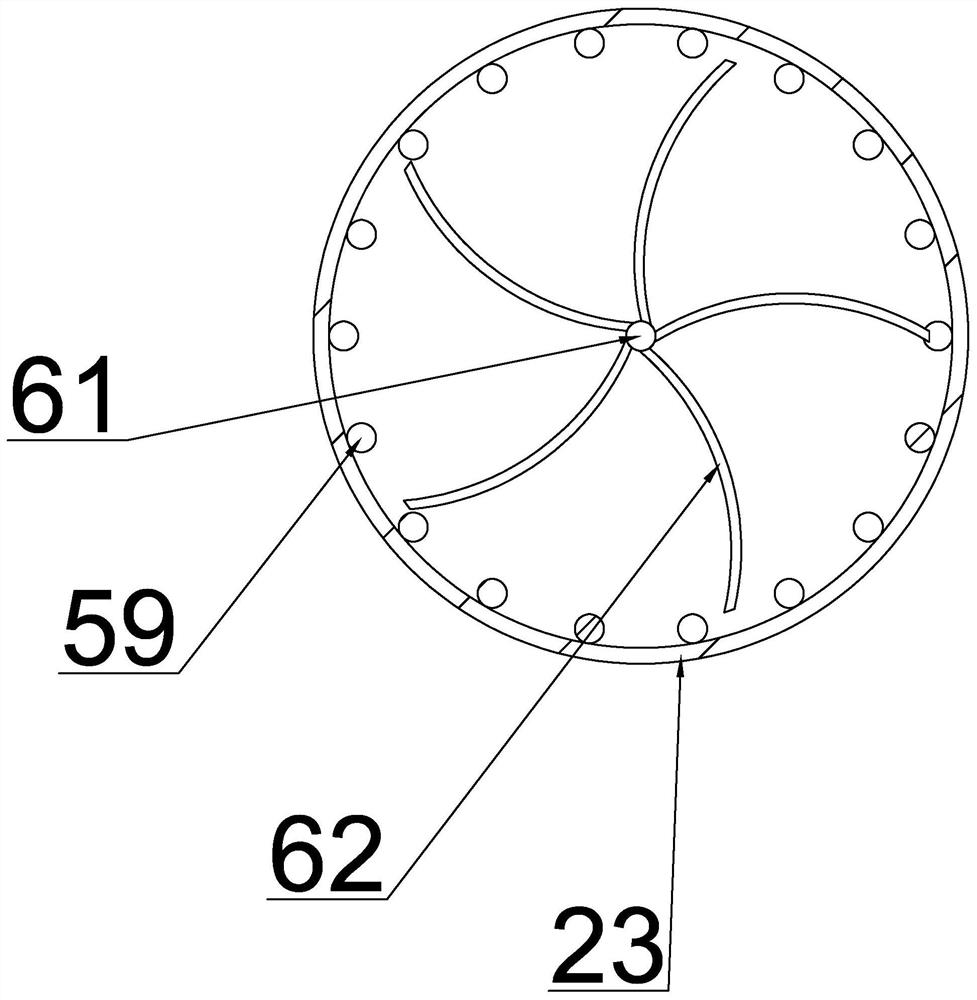

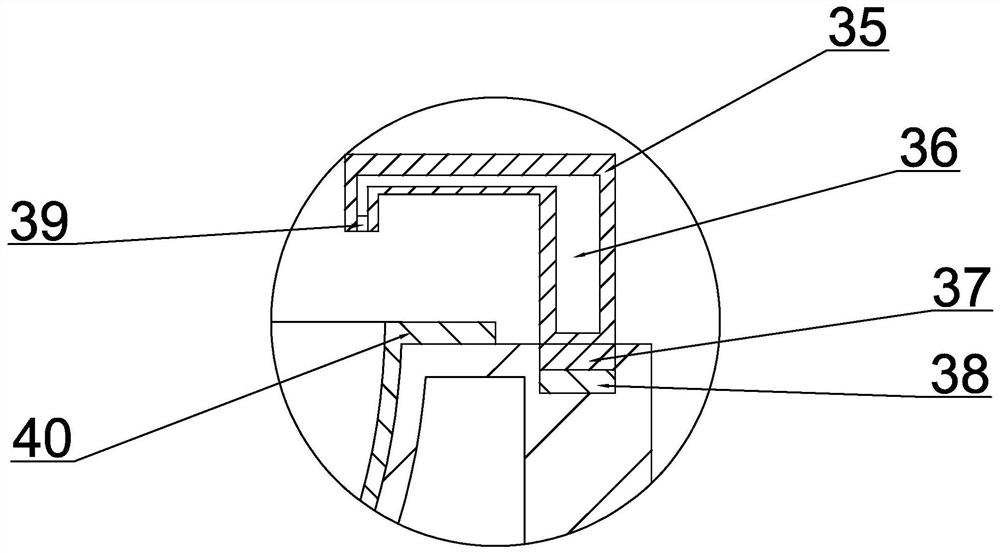

[0027] Such as figure 1 As shown, a manufacturing process of an aluminum alloy pad printing silicone head includes a body 10, the body 10 is provided with a working chamber 26, and the upper side wall of the working chamber 26 is fixedly provided with a hydraulic rod 25;

[0028] The shaking mechanism A01, the shaking mechanism A01 is arranged on the side wall of the working chamber 26, the shaking mechanism A01 can make the cleaning effect better;

[0029] Glue dispensing mechanism A02, the glue dispensing mechanism A02 is set on the upper part of the working chamber 26, the glue dispensing mechanism A02 can configure the silicone head according to the appropriate ratio;

[0030] The cleaning mechanism A03 is arranged on the lower side of the glue dispensing mechanism A02, and the glue dispensing mechanism A02 can clean the mould.

[0031] combine Figure 1-5 As shown, the shaking mechanism A01 includes a fourth motor 22, the fourth motor 22 is fixedly arranged on the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com