Pekk powder hot pressing mold and molding method based on universal testing machine

A universal testing machine and hot press forming technology, which is applied in the field of powder hot press forming, can solve the problem of large temperature gradient between the sample and the mold surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

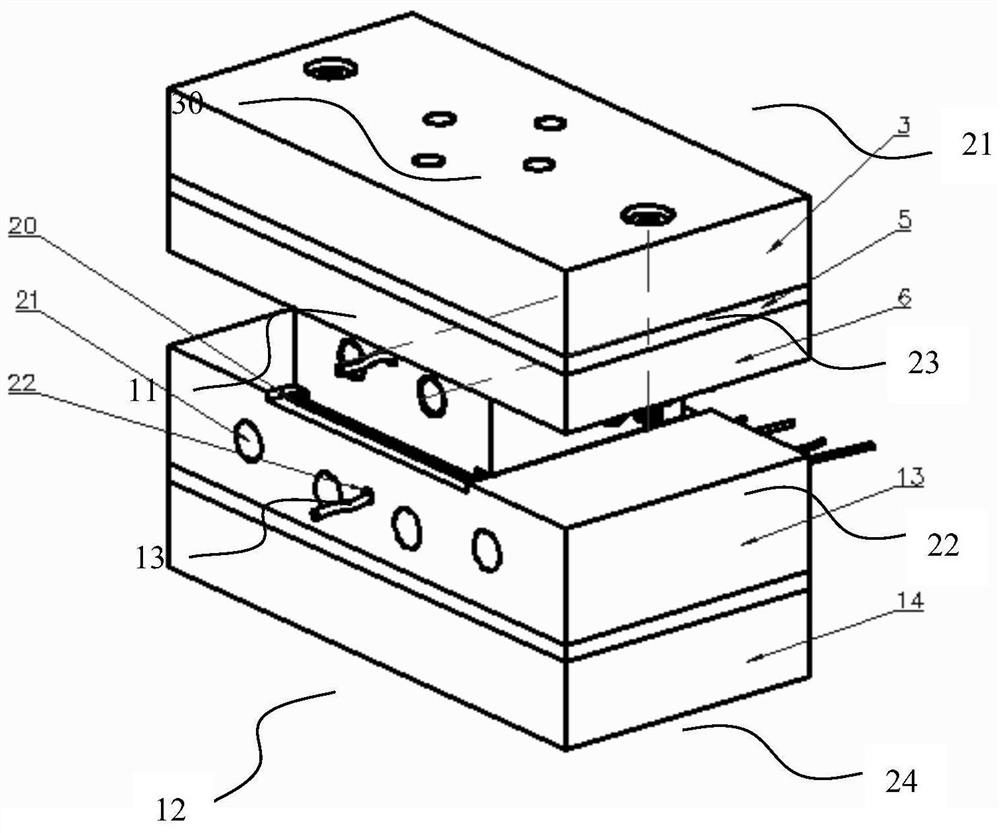

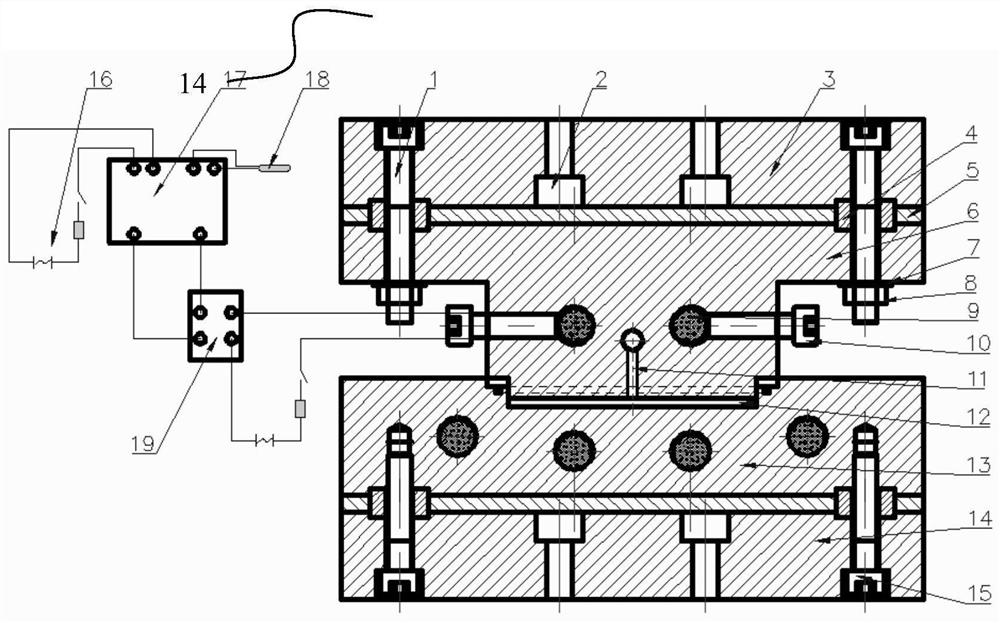

[0034] like Figure 1-2 As shown in the present invention, a PEKK powder hot pressing mold and molding method based on a universal testing machine, comprising an upper template 3, a lower template 14, a punch 6, a concave mold 13, a thermal insulation cotton 5, a support column 4, Fastening bolt 1, gasket 7, nut 8, set screw 15, heating rod 9, thermocouple 18, high-precision temperature PID controller 17, solid state relay 19, temperature control circuit 16 and PEKK powder 12 to be formed;

[0035] There are four testing machine connecting holes 2 distributed along the center in the middle of the upper die plate 3, which are used to connect the upper die 3 part with the upper chuck of the universal testing machine through the set screw 15. The diameter of the through hole is larger than the diameter of the screw 15. Diameter, to prevent gaps during connection, two stepped holes are opened on both sides of the upper template 3 to connect the support column 4 and the punch 6. A...

specific Embodiment approach

[0056] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Based on the PEKK powder hot pressing mold and the molding method of the universal testing machine,

[0057] In this embodiment, different materials can be replaced and sheets of different thicknesses can be formed, and the temperature and pressure can also be regulated, so as to realize powder hot pressing of sheets of different types and thicknesses under the conditions of different process parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com