Conveying, guiding and separating device for steel production and processing

A technology of steel and mounting brackets, applied in conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of limited application scope of conveying mechanisms, inability to adjust the plane and angle of steel conveying, and achieve a variety of conveying methods and a wide range of applications. , The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

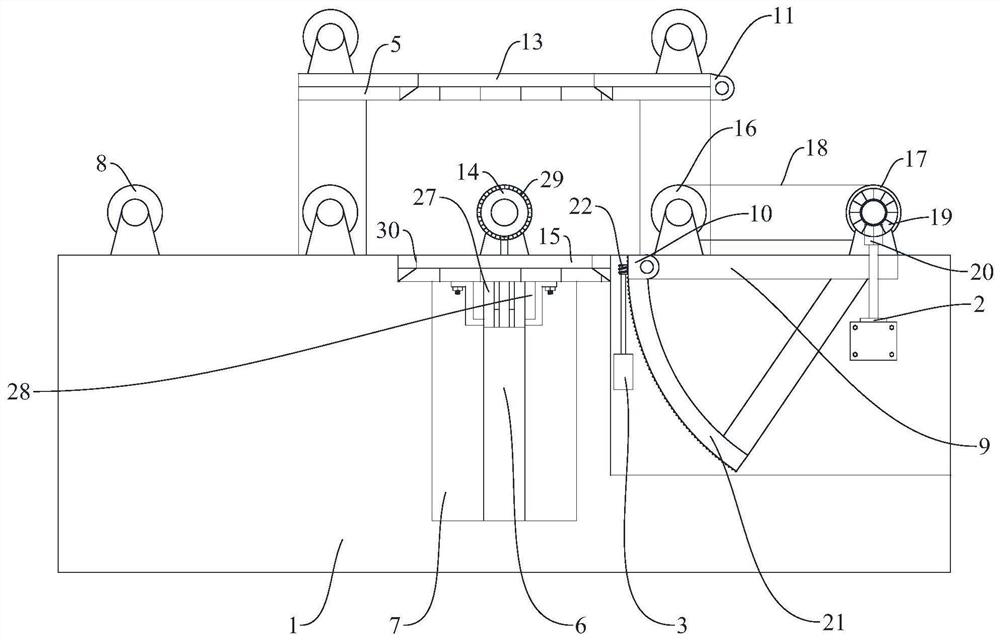

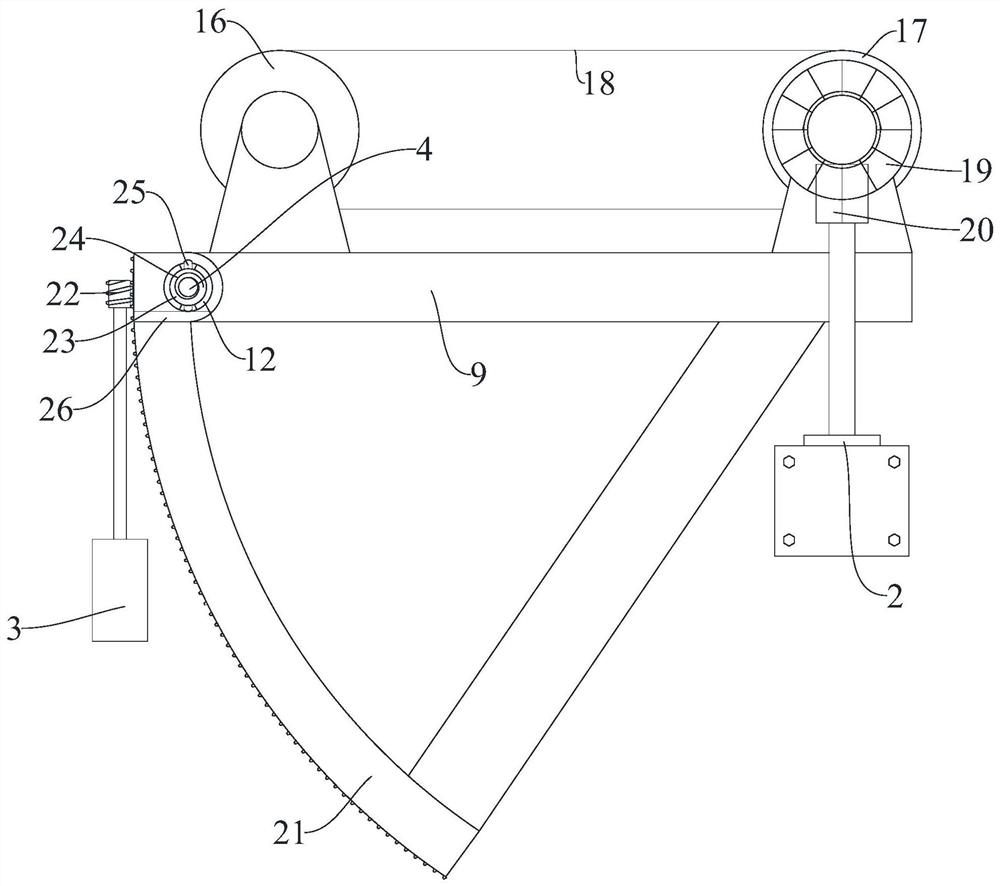

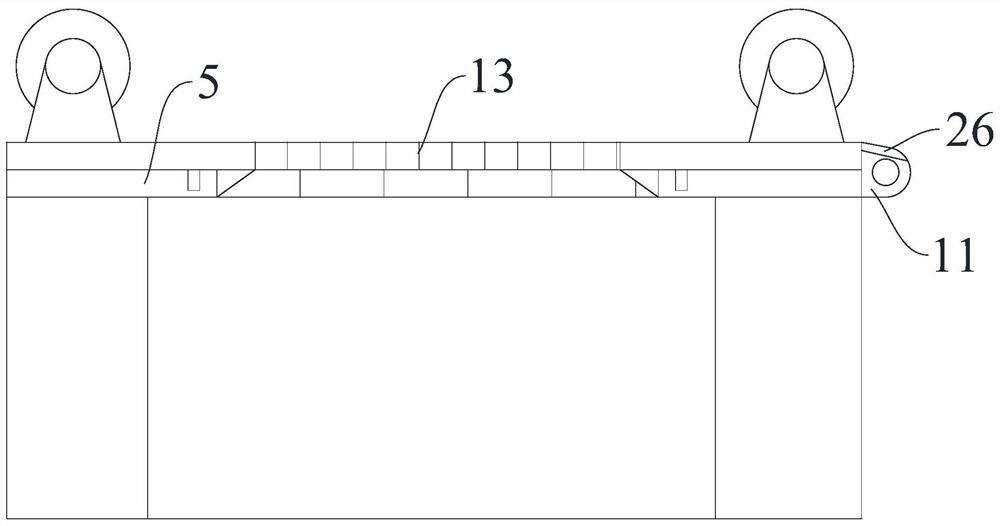

[0024] Embodiment: Use the drive motor 2 to control the internal conveyor belt mechanism, and then use the internal motor 28 to control the main drive roller 14. When the adjustment motor 3 drives the flip adjustment frame 9 to rise, the electronically controlled telescopic strut 6 can be selected separately Or linkage rises, so just can form multi-platform conveyance, can also be provided with laterally conveying guide-off device on the outside of circular adjustment console 15 simultaneously, so just can carry out multi-angle conveyance, only need to adjust the circular adjustment console 15 The main driving roller 14 can be higher than the bottom conveying roller 8 and the driven roller shaft, and at the same time, a water-cooling injection mechanism can be installed on the circular adjustment console 15, so that the cooling operation can be performed at different heights. It is necessary to set up three layers of decoupling devices. It is only necessary to change the number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com