Turnover mechanism based on double-rocker connecting rod

A technology of flipping mechanism and double rocker, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of limited funds and space for small and micro enterprises, not suitable for small and medium-sized enterprises, complex mechanical structure, etc., to reduce weight and volume. , to ensure stability, the effect of simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

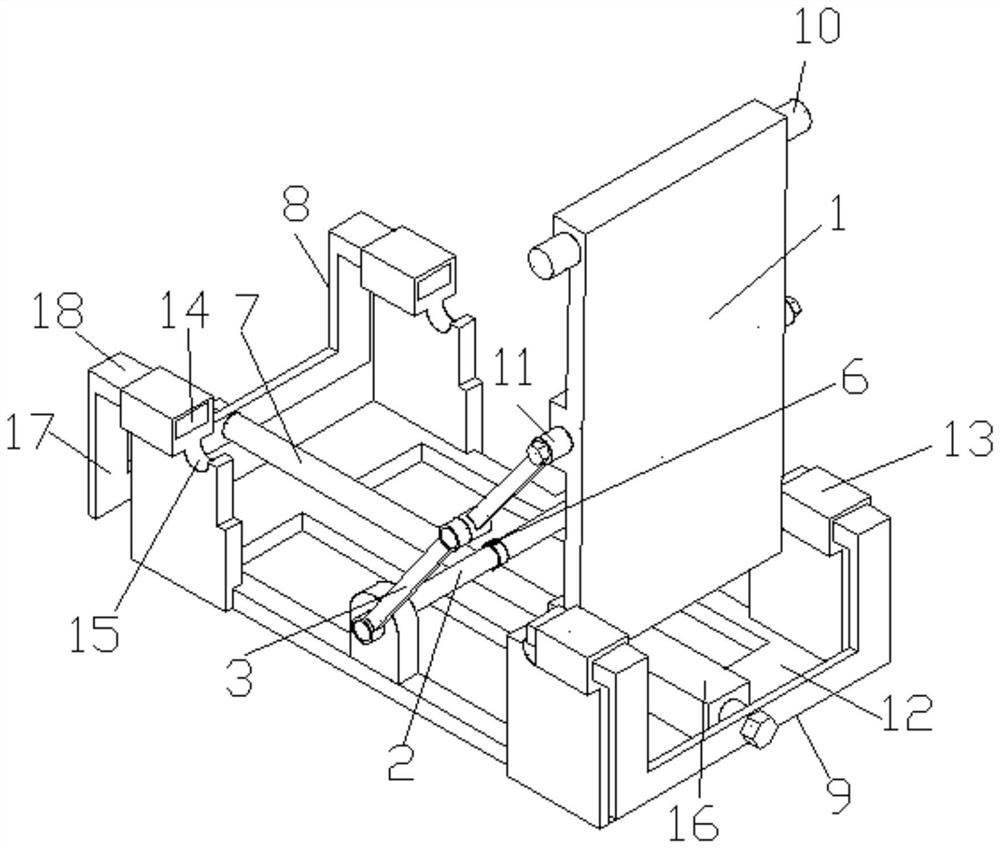

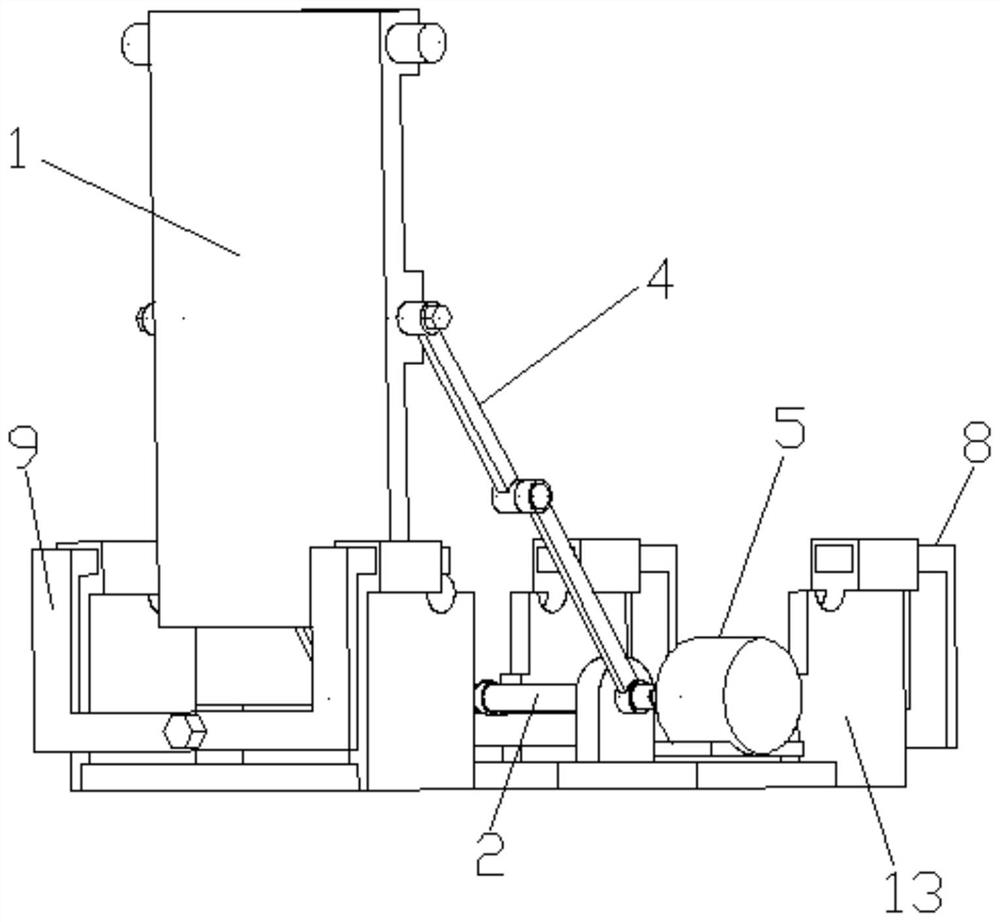

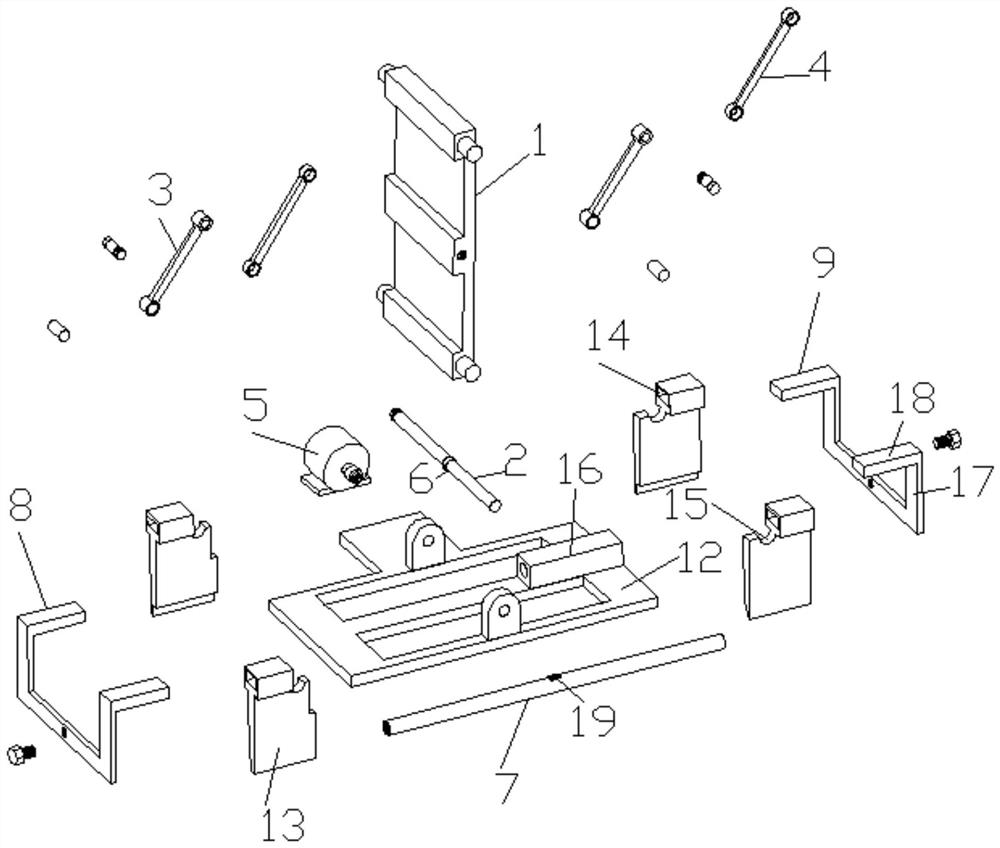

[0022] Such as Figure 1-Figure 2 Shown a kind of turning mechanism based on double rocker link, comprises turning plate 1, double rocker link assembly, sliding limit assembly and support seat.

[0023] Specifically, the turning board 1 includes a rectangular turning board main body and two rocker mounting parts 11 arranged on the front and rear sides of the middle section of the turning board main body. Described two rotating shafts 10 are respectively arranged on the left and right ends of the turnover plate main body. The turnover plate 1 is arranged above the supporting seat. Described supporting base comprises base plate 12 and the bearing 13 that is arranged on the upper corner of base plate 12; The top of described bearing 13 is provided with sliding groove 14 and fixing groove 15; When the turning plate 1 rotates 90 degrees clockwise from the horizontal direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com