Steel rope winding device convenient to disassemble and assemble

A winding device and steel rope technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of troublesome replacement and inability to realize automatic roll change, and achieve convenient operation, easy automatic roll change, cleverly structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

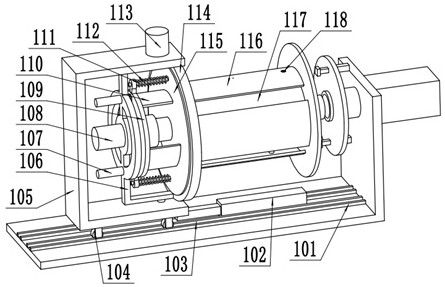

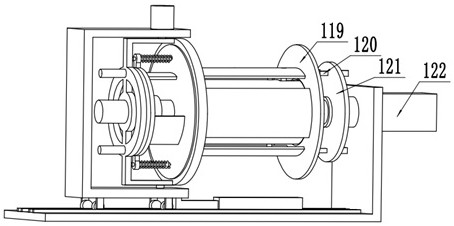

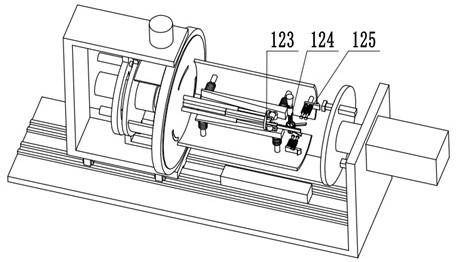

[0016] Example: such as figure 1 A wire rope winding device that is easy to disassemble and install is shown, including a base 101, a first hydraulic cylinder 102, a slide rail 103, wheels 104, a sliding frame 105, a turret 106, a rotating motor 113, a fixed ring 114, and a rotating plate 115, arc plate 116, fixed cylinder 117, rope inlet 118, movable baffle 119, electromagnet 120, telescopic plate 121, third hydraulic cylinder 122, diameter control assembly 123, steel rope fixing assembly 124, movable plate fixing Assembly 125, the base 101 is installed on the ground, the first hydraulic cylinder 102 is fixedly installed on the base 101, the base 101 is provided with a slide rail 103, the wheels 104 are rotatably installed under the slide frame 105, and the wheels 104 roll on the slide rail 103 , the turret 106 is rotatably mounted on the sliding frame 105, the sliding frame 105 is fixedly connected with the output shaft of the rotating motor 113, the rotating motor 113 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com