A comprehensive thermal management system for a large-scale alkaline electrolysis water hydrogen production device

A technology of thermal management system and hydrogen production device, applied in electrolysis components, electrolysis process, heat storage equipment, etc., can solve the problems of continuous production obstacles, difficult dynamic balance of working conditions, affecting the temperature of heat exchange medium, etc., so as to improve heat recovery. Efficiency, reduce adverse influence factors, reduce the effect of parameter error alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

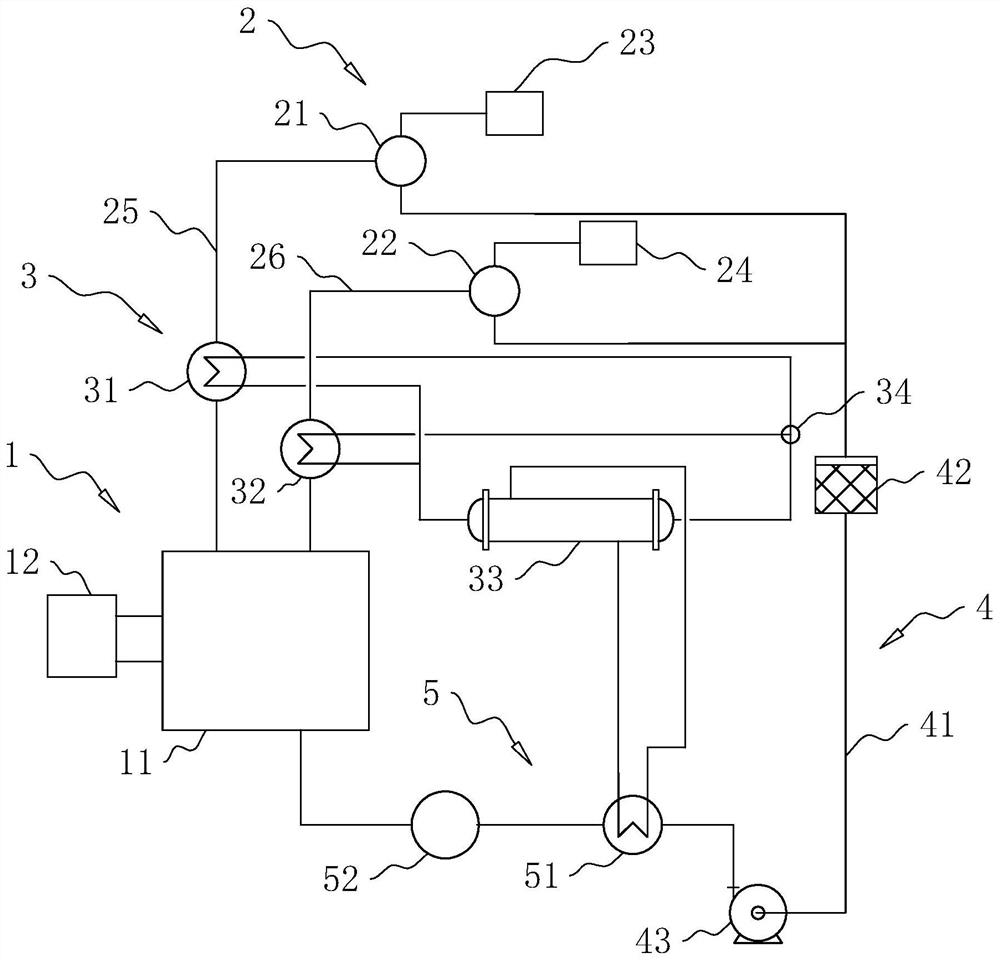

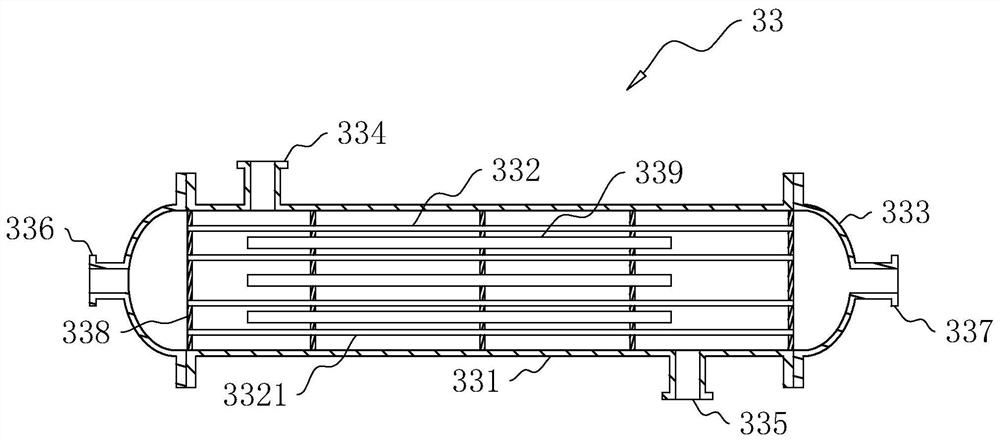

[0050] The comprehensive thermal management system of a large-scale alkaline electrolyzed water hydrogen production plant, as attached figure 1 As shown, it includes an alkaline electrolyzed water hydrogen production unit 1 , a heat recovery unit 3 , a heat redistribution unit 5 , a gas phase treatment unit 2 and a liquid phase circulation unit 4 .

[0051] The alkaline electrolyzed water hydrogen production unit 1 includes an electrolytic cell 11 and a rectifier transformer 12 electrically connected to the electrolytic cell 11 . The electrolytic cell 11 is provided with a positive electrode chamber and a negative electrode chamber, and the positive electrode chamber and the negative electrode chamber store alkali liquor and are separated by an ion membrane. The rectifier transformer 12 is energized to the electrolytic tank 11 to electrolyze the lye in the electrolytic tank 11 .

[0052] The gas phase processing unit 2 includes a hydrogen gas-liquid separator 21 , an oxygen g...

Embodiment 2

[0079] The comprehensive thermal management system of a large-scale alkaline electrolyzed water hydrogen production plant, as attached Figure 4 As shown, based on Example 1, the difference is that the heat recovery unit 3 in Example 2 also includes a direct preheater 35 on the hydrogen side and a direct preheater 36 on the oxygen side. The gas phase processing unit 2 includes a delivery pipe for the infusion phase, which is divided into a hydrogen-side delivery pipe 27 connected to the hydrogen gas-liquid separator 21 and an oxygen-side delivery pipe 28 connected to the oxygen gas-liquid separator 22 .

[0080] The direct preheater 35 on the hydrogen side is installed and connected to the hydrogen production pipe section 25 , the hydrogen produced in the electrolyzer 11 flows through the direct preheater 35 on the hydrogen side, and then enters the hydrogen heat recovery heat exchanger 31 .

[0081] The upstream of the hydrogen side delivery pipe 27 is connected to the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com