Overall lifting automatic building construction platform

A technology for overall lifting and building construction, applied in construction, lifting devices, building structures, etc., can solve problems such as low degree of automation, resource waste environment, and low safety factor, and achieve reliable operation, cost saving, and high reuse rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

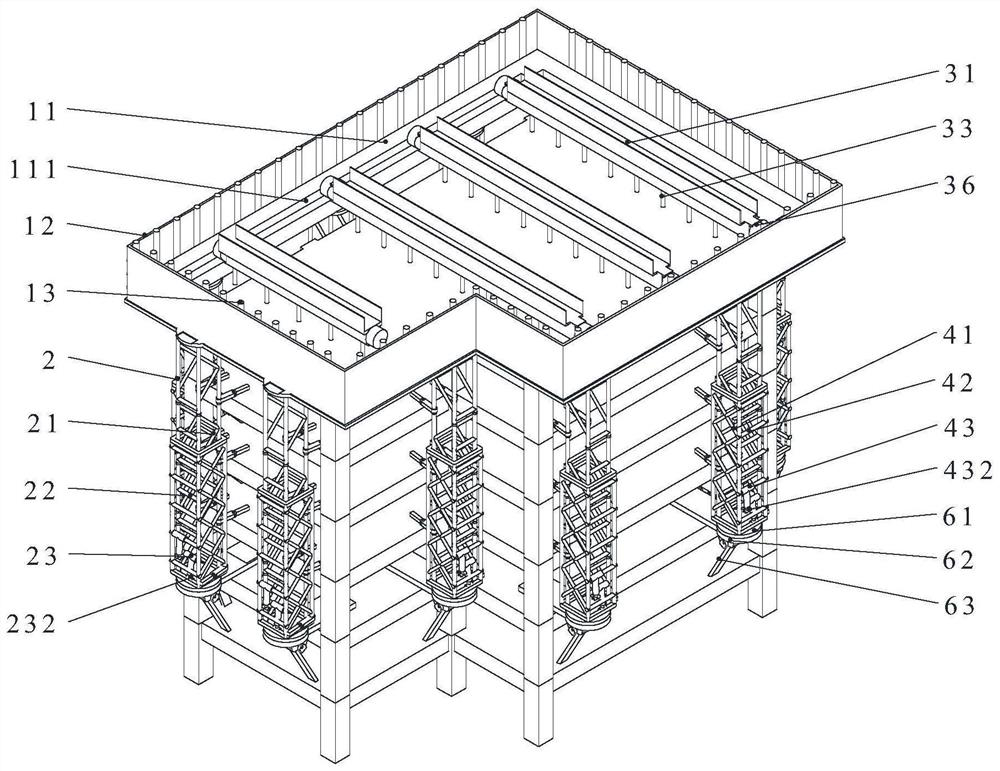

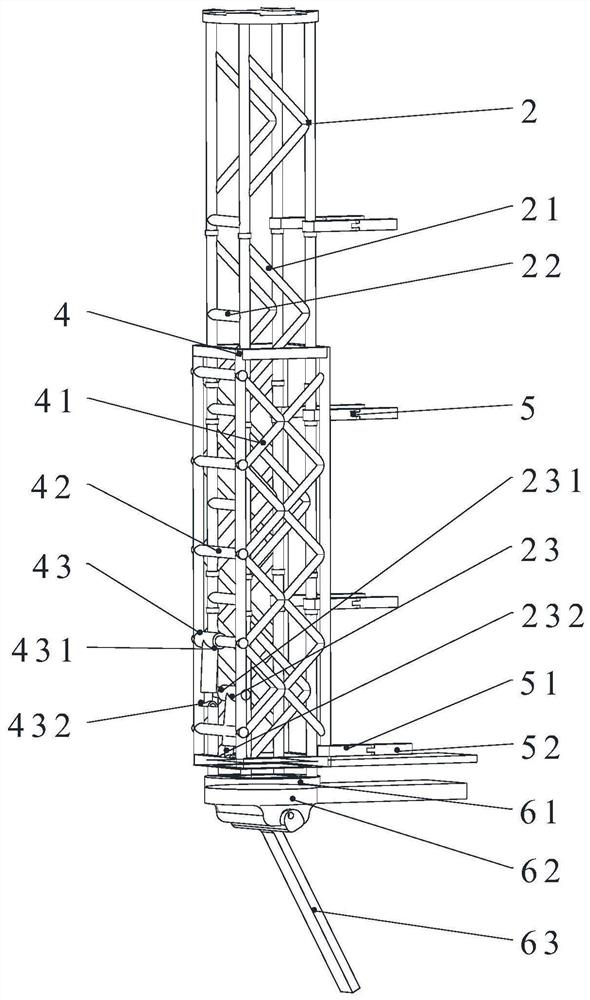

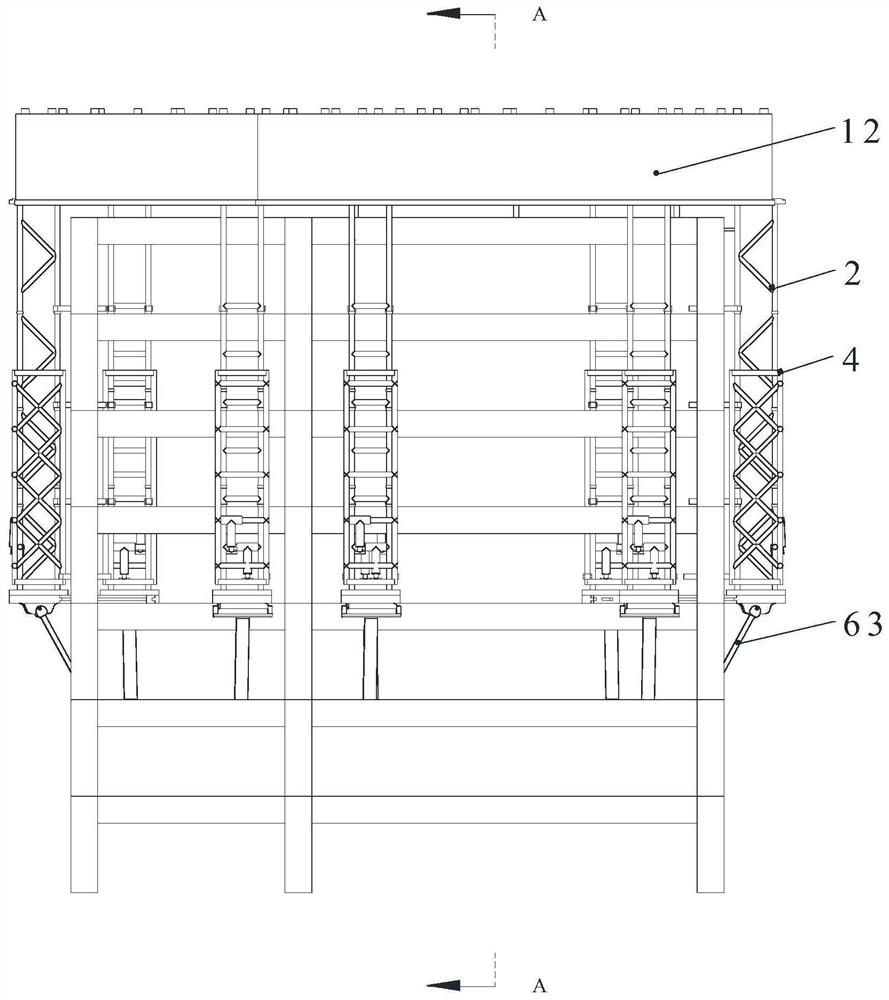

[0030] In one of the above embodiments, the construction platform, lifting device, hoisting equipment and auxiliary facilities are used to realize modularized and automated continuous building construction. In this embodiment, the construction platform bears the weight of hoisting equipment, auxiliary facilities, and pouring floors, and the lifting device can realize independent rise or fall, and transfer the load of the entire construction platform to the load-bearing beams of the house. When pouring concrete, the hoisting equipment lifts the construction floor through the boom 33, the prefabricated slab 34 and the quick release 35. After the pouring is completed, the concrete and the prefabricated slab 34 are condensed into one. The entire building construction platform is automated and modularized, eliminating the need for manual handling of equipment and removal of molds.

[0031] The integral lifting automatic building construction platform provided by the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com