Method for reducing metal area

An area and metal technology, applied in the field of reducing the metal area, can solve the problems of inability to punch two through holes, too dense lines, time-consuming and labor-intensive, etc., to save time and labor costs, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] like image 3 As shown, it is a flow chart of a method of shrinking a metal area according to an embodiment of the present invention; the method of shrinking the metal area of the present invention includes the following steps:

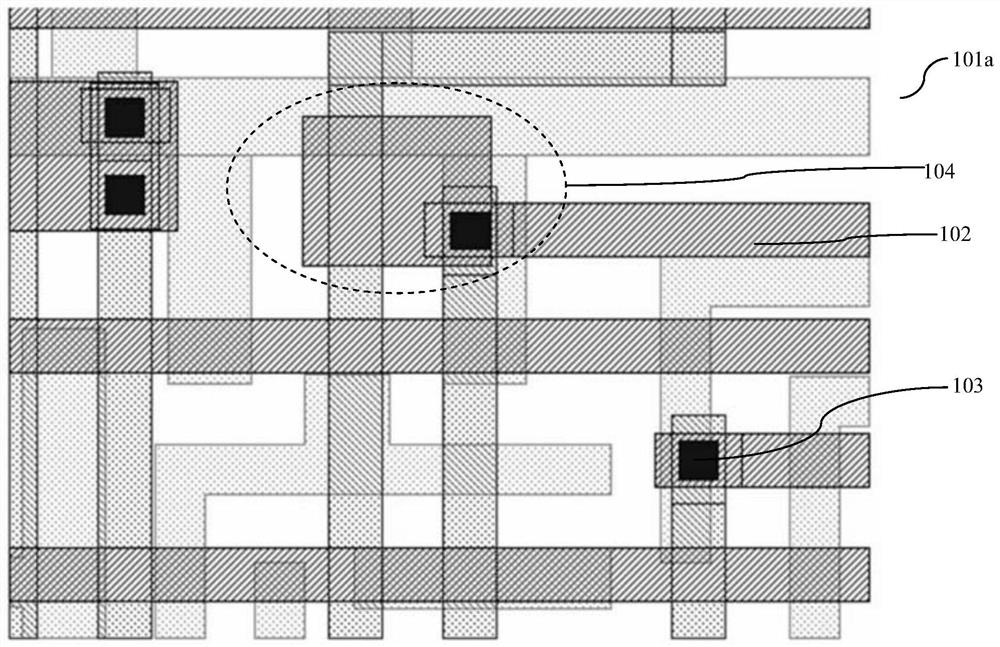

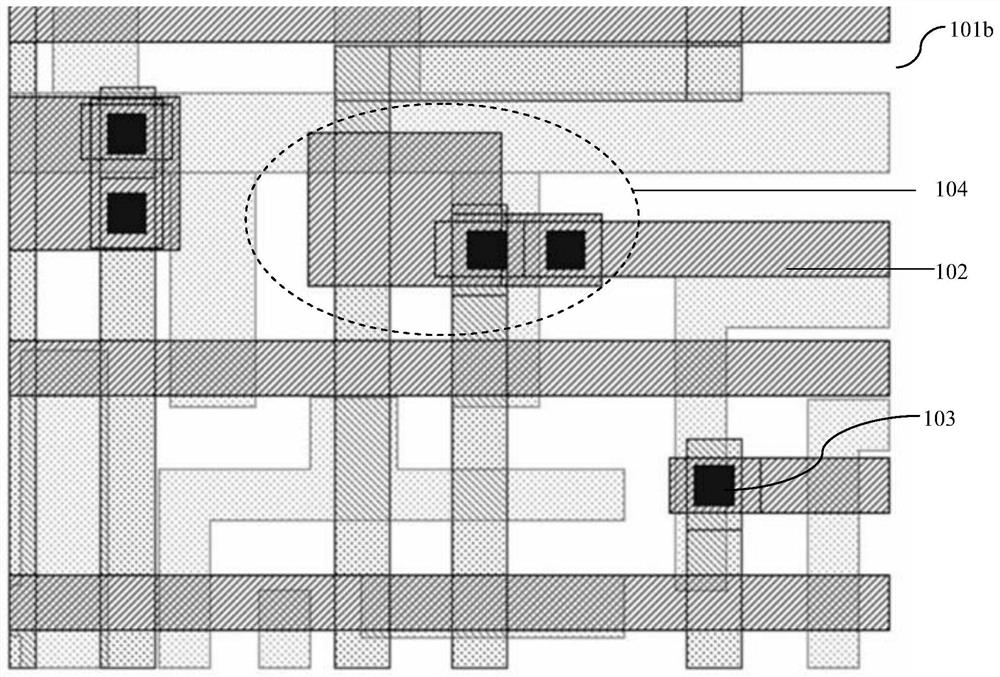

[0045] Prior to a follow-up step, including: the original pattern of the large metal block 202 from the layout data. like Figure 4A As shown, it is a metal line 201 in the vicinity of a large metal block 202 in the method of the embodiment of the present invention; Figure 4A As shown, a large metal block 202 is provided in the metal line 201, and two contact holes 203 and 1 through hole 204 are provided on the large metal block 202.

[0046] It is better to automatically pick the original graphic of the large metal block 202 from the graph data through the SIZING function. The SIZING function is implemented by the C ++ language. The SIZING function can be used in the layout tool, or in addition to program implementation; the SIZING function can se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com