10-core connector with airtight waterproof function

A connector and airtight technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, etc. It can solve the problems of connectors not having waterproof performance, large outer diameter of waterproof connectors, and inconvenience for users. , to increase connection stability, light weight, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

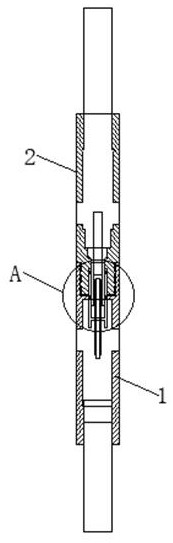

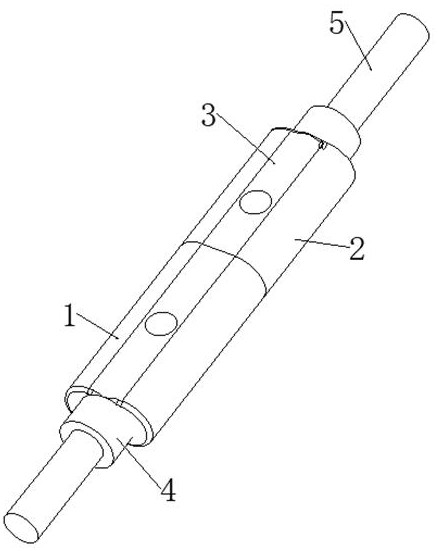

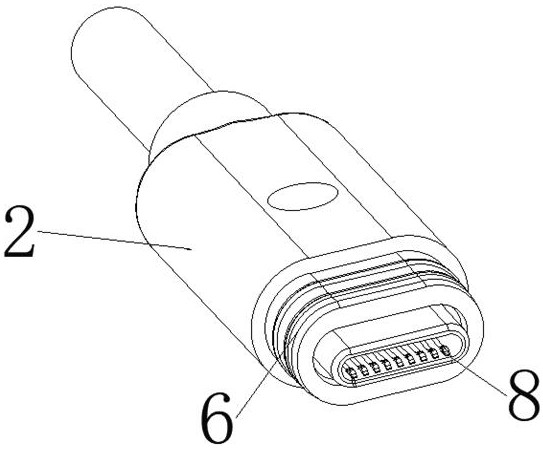

[0026] Please refer to Figure 1-6 As shown, the present invention provides a connector female end 1 and a connector male end 2. The connector female end 1 and the connector male end 2 are respectively provided with an insertion slot 7 and an insertion block 6. A PCB terminal 8 is provided inside the connection block 6, and a molded terminal 11 is provided inside the insertion slot 7, and a first conductive sheet 9 and a second conductive sheet 10 are respectively provided inside the PCB terminal 8 and the molded terminal 11. The socket block 6 is inserted into the socket slot 7, the PCB terminal 8 is inserted into the molded terminal 11, the first conductive sheet 9 and the second conductive sheet 10 interfere with each other, and the connector female end 1 There are anti-fooling grooves 3 on the outside of the connector male end 2, and the two groups of anti-fooling grooves 3 correspond to each other. The connector female end 1 and the connector male end 2 use a turn-up stru...

Embodiment 2

[0029] Please refer to Figure 1-6 As shown, the other parts of this embodiment 2 are the same as the implementation of embodiment 1. The difference is that the present invention provides that both ends of the connector female end 1 and the connector male end 2 are provided with wiring 5, and the two groups of Protective sleeves 4 are provided at the connections between the wiring 5 and the connector female end 1 and the connector male end 2 respectively, and hooks are provided at the places where the first conductive sheet 9 is in contact with the second conductive sheet 10, The hook is in contact with the second conductive sheet 10, and the connector female end 1 and the connector male end 2 are both equipped with a shell, the shell is made of TPU93 material, and the PCB terminal 8 and the molded terminal 11 can pass through The rated current is 3A, and the peak value is 5A. The two sets of protective sleeves 4 are integrated with the connector female end 1 and the connector...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap