Device for producing bead cores for tyres by crimping a braided wire, with optical tracking of the cutting and crimping point

A bead core and equipment technology, applied to tires, household appliances, and other household appliances, can solve problems such as waste, scrapped raw materials and energy for bead core wires, and difficulty in duplication, so as to ensure scrap rate, improve production efficiency, The effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

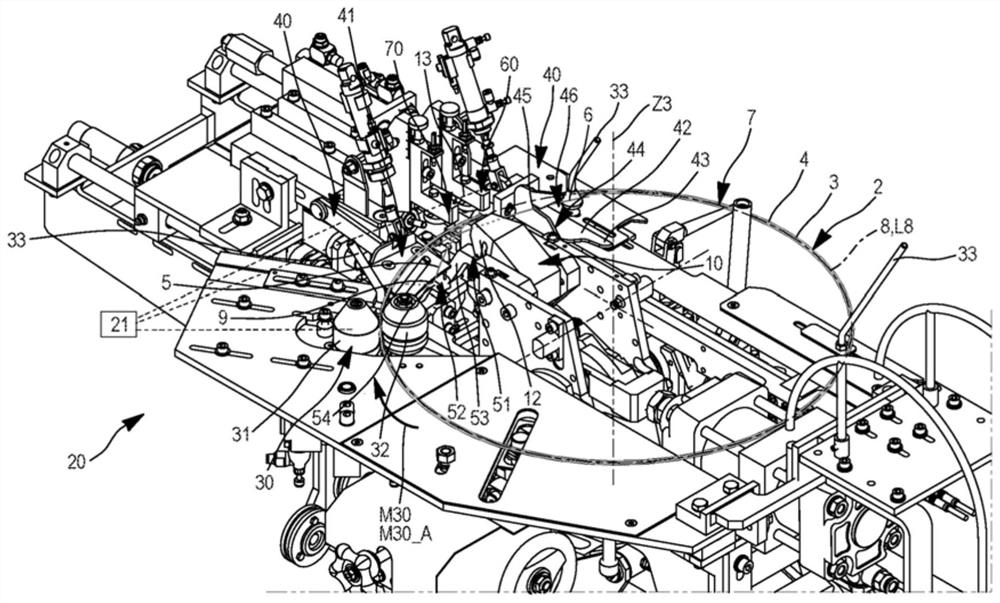

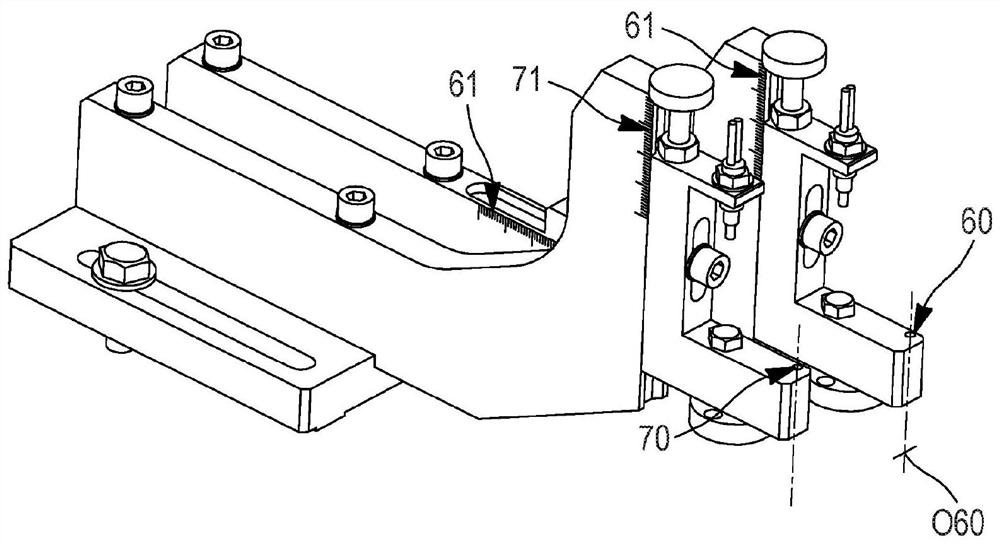

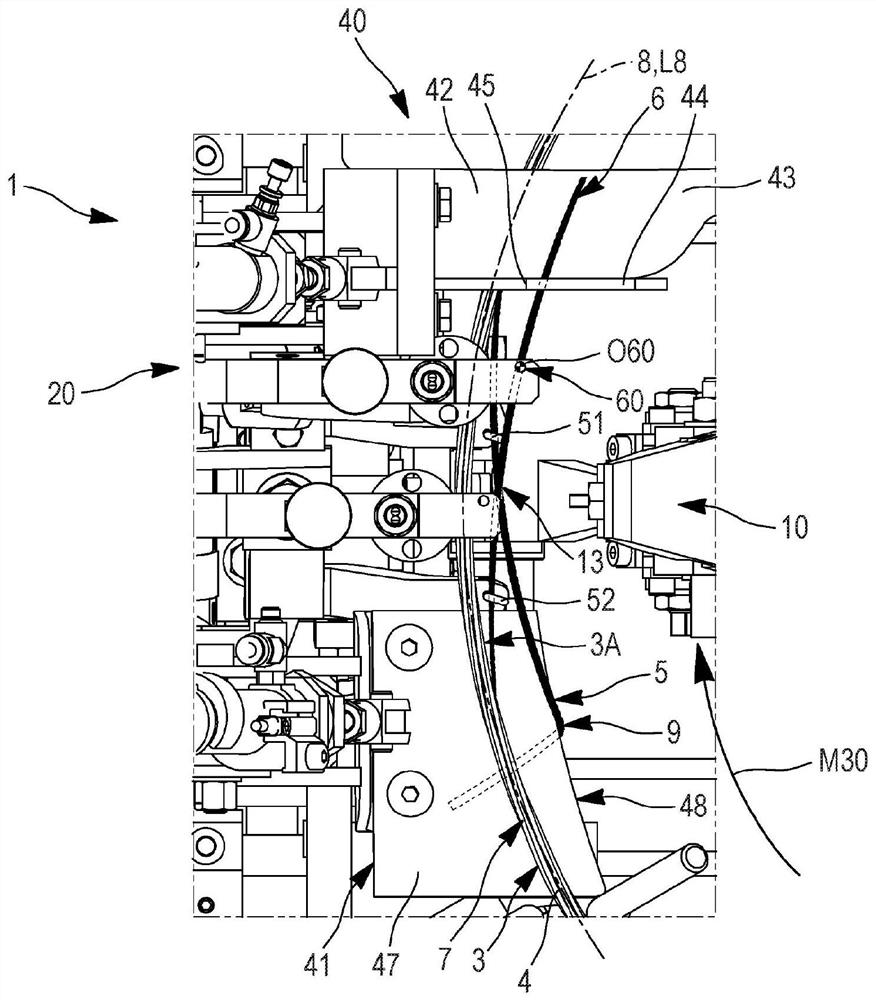

[0040] The invention relates to a plant 1 for manufacturing an annular bead core element 2 .

[0041] This annular bead core element 2 is intended to reinforce tires, in particular pneumatic tires.

[0042] By way of example, the annular bead core elements 2 intended to hold said pneumatic tire on the rim may be designed for the size (in this case in particular the diameter of the rim) Corresponding) Pneumatic tires between 13 inches and 24 inches. The invention is naturally suitable for the manufacture of bead core wires 2 designed for pneumatic tires for private passenger vehicles (which in particular have the above-mentioned dimensions), but also for the manufacture of tires intended for pneumatic tires intended for heavy goods vehicles or civil engineering machinery. Core wire.

[0043] The device comprises an assembly station 10 .

[0044] This assembly station 10 is intended to receive a braided annular body 3 comprising at least one wire, referred to as “braiding wire”...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com