Automatic identification strip cutting machine for tape measure

An automatic identification and cutting machine technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as difficulty in maintaining consistent punching accuracy of ruler tape, inability to perform high-speed operation, and difficulty in controlling product quality. The interface is simple and easy to learn, the effect of reducing costs and expenses, and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

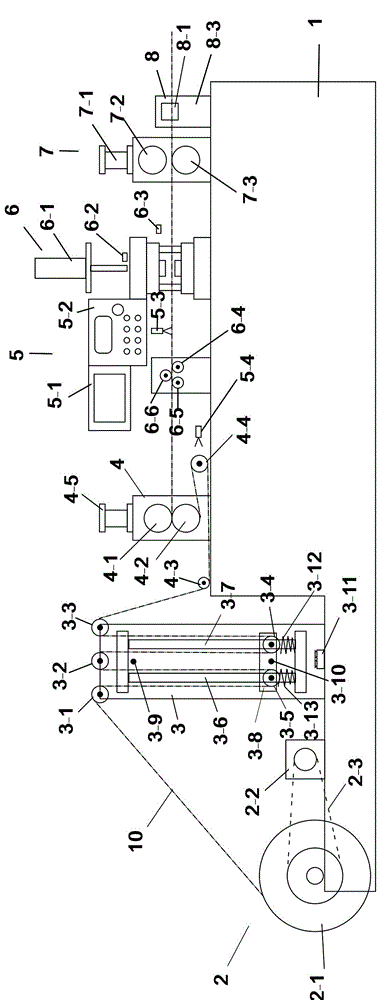

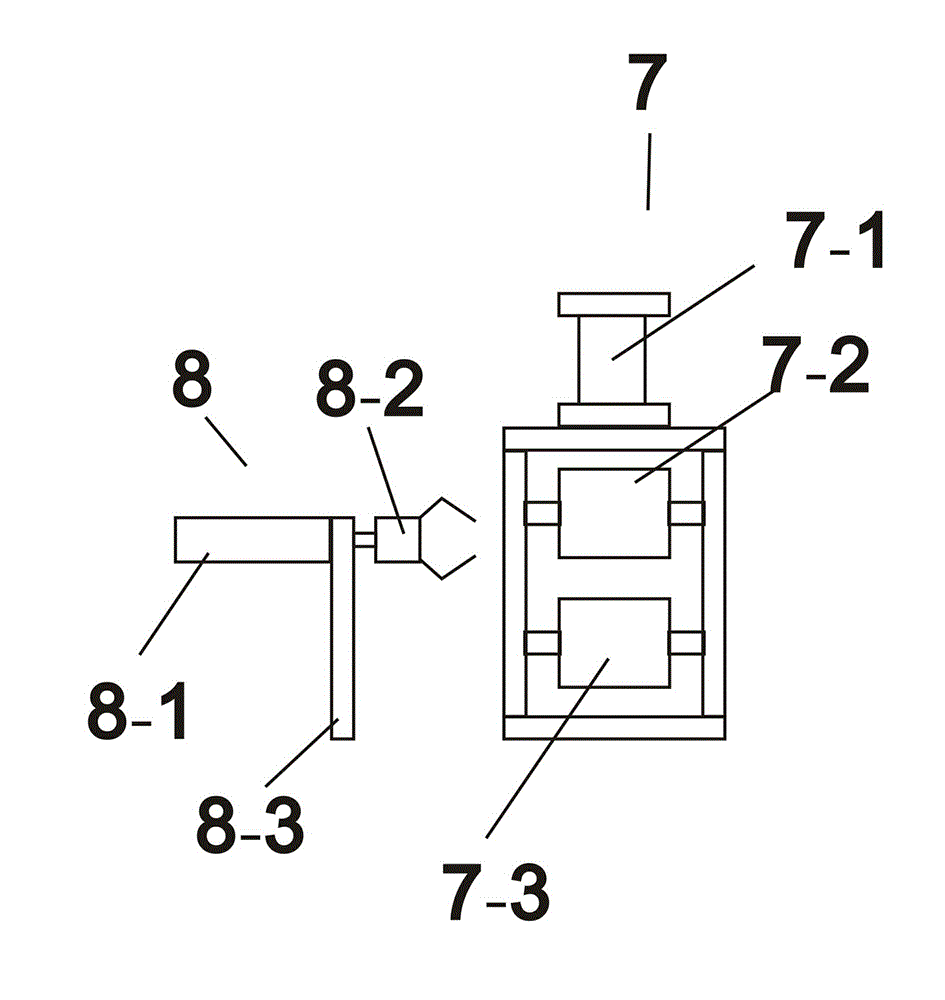

[0020] Such as figure 1 , 2 As shown, a tape cutting machine is characterized in that it includes a frame 1, and an unwinding mechanism 2, a tension mechanism 3, a tape feeding mechanism 4, a visual control system 5, and a punching device that are sequentially arranged on the frame 1 6, tape-out device 7, sorting device 8, described tape feeding mechanism 4 comprises upper wheel-4-1, lower wheel-4-2, cylinder-4-5, described cylinder-4-5 and upper Wheel one 4-1 is connected, and described upper wheel one 4-1 is tangent up and down with lower wheel one 4-2, and described chi tape 10 passes between upper wheel one 4-1 and lower wheel one 4-2 Pass;

[0021] The visual control system 5 includes a controller 5-2 and a display screen 5-1 connected to the controller 5-2;

[0022] The punching device 6 includes a guide wheel set and a punching machine, wherein the guide wheel set is composed of three guide wheels 6-4, four guide wheels 6-5, and five guide wheels 6-6, wherein thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com