Epoxy resin filter with filter core convenient to replace

A technology for replacing epoxy resin and filter elements, which is applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of reducing the filtration efficiency of epoxy resin and wasting working time, so as to improve the filtration effect, improve work efficiency, The effect of increasing work output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

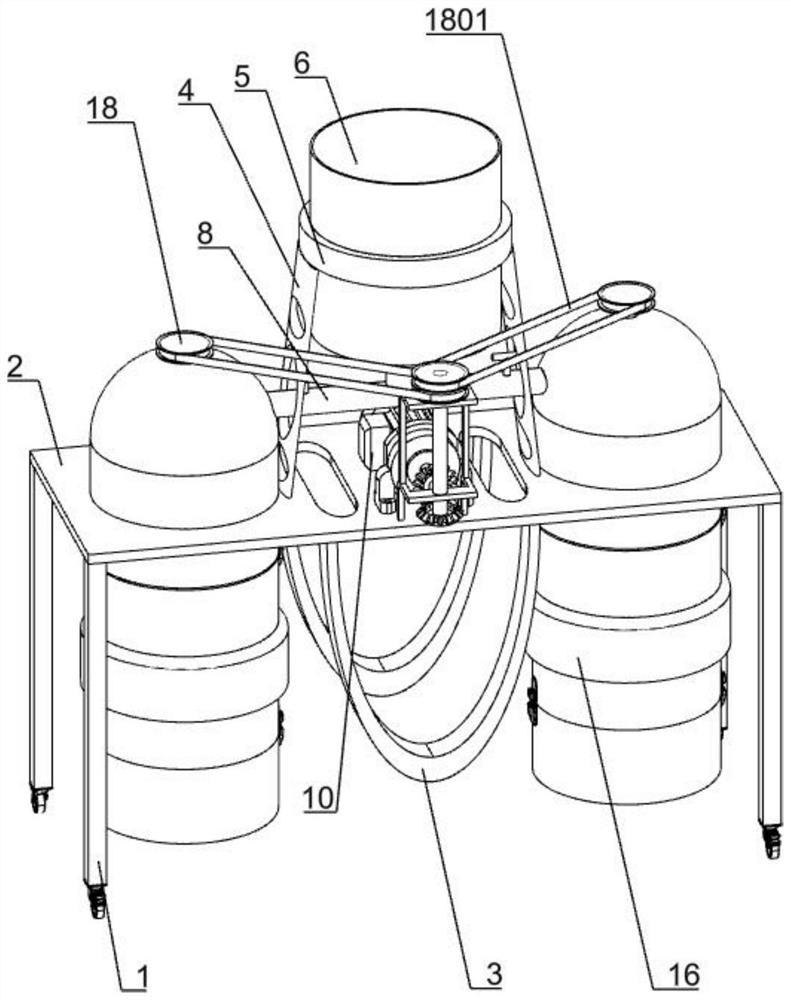

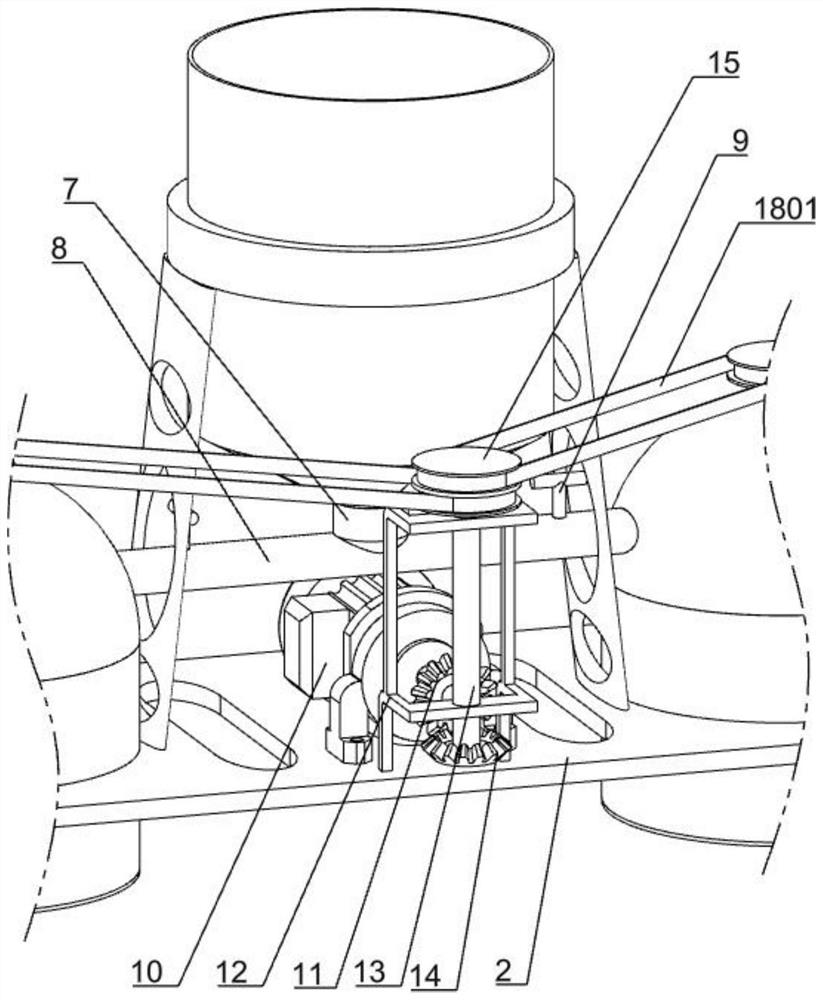

[0034] Such as figure 1As shown, it includes a support leg 1, a rectangular plate 2, a U-shaped frame 3, a blanking assembly, a power assembly, a filter assembly and a stirring assembly. There are four support legs 1, and the rectangular plate 2 is fixedly installed on the top of the four support legs 1. , there are two U-shaped frames 3, the two U-shaped frames 3 are fixedly installed on the lower side of the rectangular plate 2, the two U-shaped frames 3 are located in the middle of the rectangular plate 2, and the blanking assembly is fixedly installed on the upper side of the rectangular plate 2, and the power The assembly is fixedly installed on the upper side of the rectangular plate 2, the power assembly is on the lower side of the blanking assembly, the filter assembly is installed on the rectangular plate 2, the filter assembly is on both sides of the blanking assembly and the power assembly, and the stirring assembly is installed inside the filter assembly.

[0035] ...

Embodiment 2

[0037] Such as figure 1 As shown, the blanking assembly includes a support plate 4, a cylindrical frame 5, a barrel 6, a short tube 7, a long tube 8 and a switch 9. There are two support plates 4, and the two support plates 4 are symmetrically installed on the rectangular plate 2. On the upper side, a cylindrical frame 5 is fixedly installed on the top of the two support plates 4, and the barrel 6 is fixedly installed inside the cylindrical frame 5. The bottom end of the barrel 6 is fixedly installed with a short tube 7, and the bottom end of the short tube 7 is fixedly installed Long pipe 8 is arranged, and long pipe 8 communicates with barrel 6 by short pipe 7, and switch 9 is all installed at the two ends of long pipe 8.

[0038] The support plate 4 plays the role of supporting the cylindrical frame 5, and the cylindrical frame 5 plays the role of installing the barrel 6. When using this device, pour epoxy resin into the barrel 6, and put one of the switches 9 on the long t...

Embodiment 3

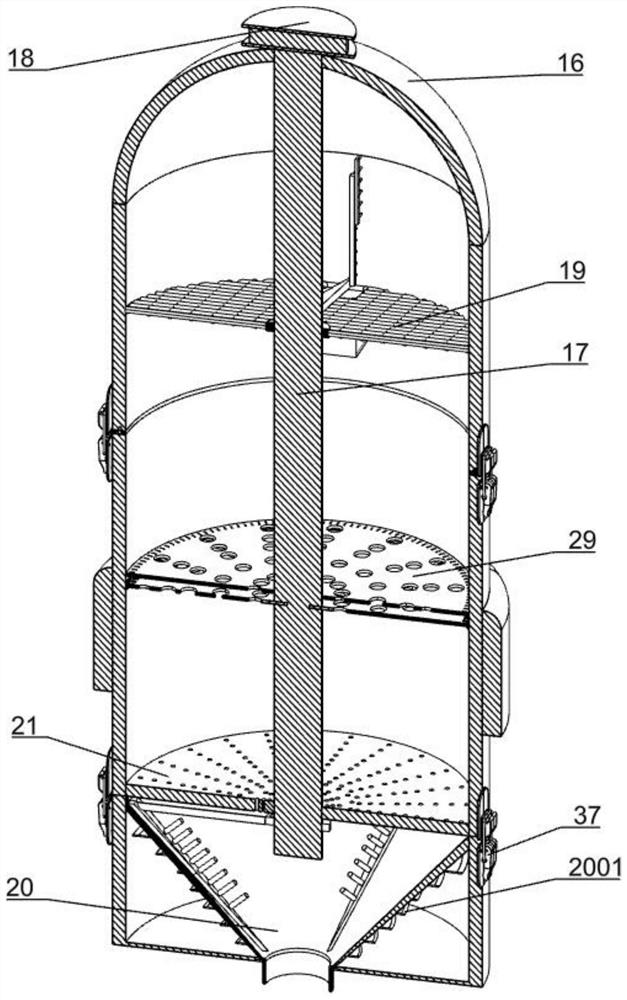

[0046] Such as Figure 9 Shown, also comprise rectangular column 25, slide bar 26, the 4th spring 27 and small cylinder 28, all are fixedly installed with rectangular column 25 on the outside of each stirring paddle 24, all have rectangular groove on each rectangular column 25, many A slide bar 26 is slidably installed in the rectangular groove on each rectangular column 25, and the top of the slide bar 26 is in contact with the filter barrel 16, and a fourth spring 27 is installed in the rectangular groove on each rectangular column 25, and the fourth spring 27 Between the lower side of the slide bar 26 and the bottom end of the rectangular column 25 , a plurality of small cylinders 28 are installed on the outside of each rectangular column 25 and the slide bar 26 .

[0047] When the stirring paddle 24 moves, it will drive the rectangular column 25 to move. When the stirring paddle 24 moves, the rectangular column 25 will move up and down. Slide down, when the rectangular co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com