Internal and external partitioned efficient production workbench of numerical control gantry machining center

A technology for machining centers and workbenches, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem that it is difficult to greatly improve the processing efficiency of machining centers, cannot effectively fix irregular workpieces, and cannot complete processing efficiency and accuracy and other problems, to achieve the effects of small space occupation, improved processing accuracy, and reduced hectic degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

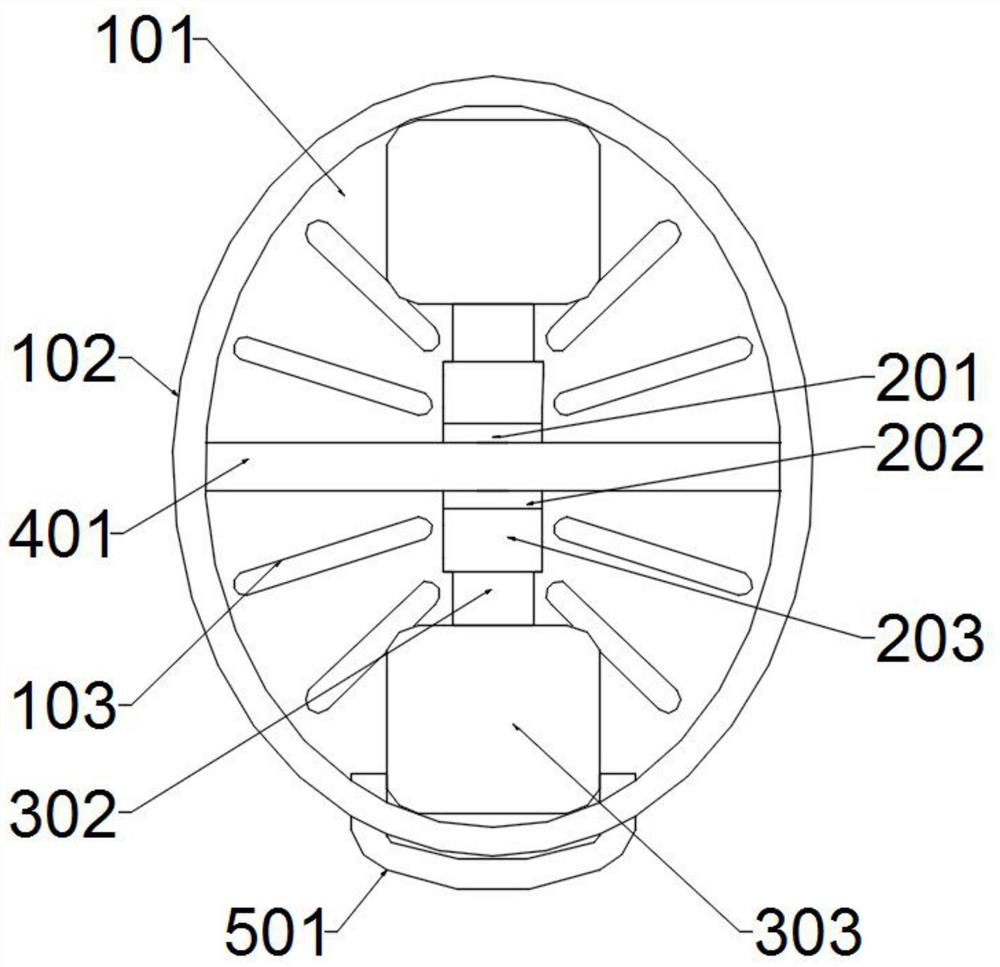

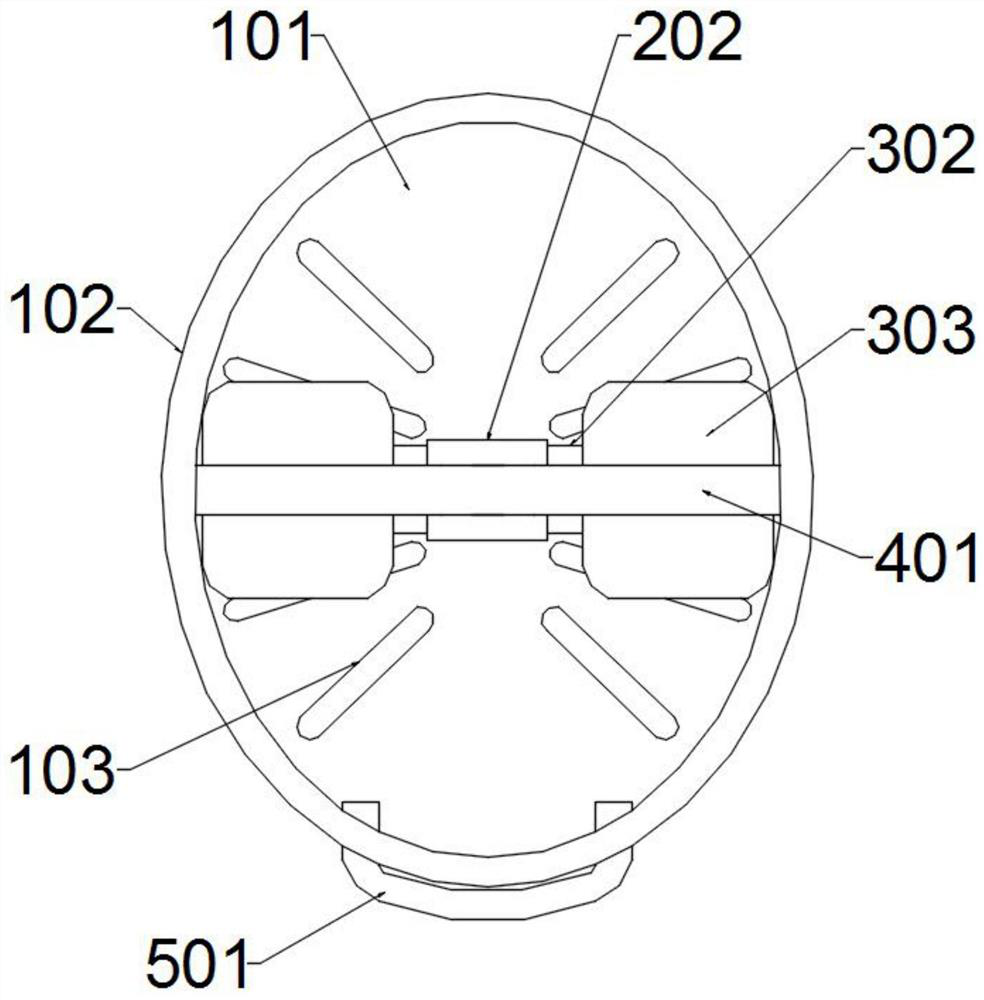

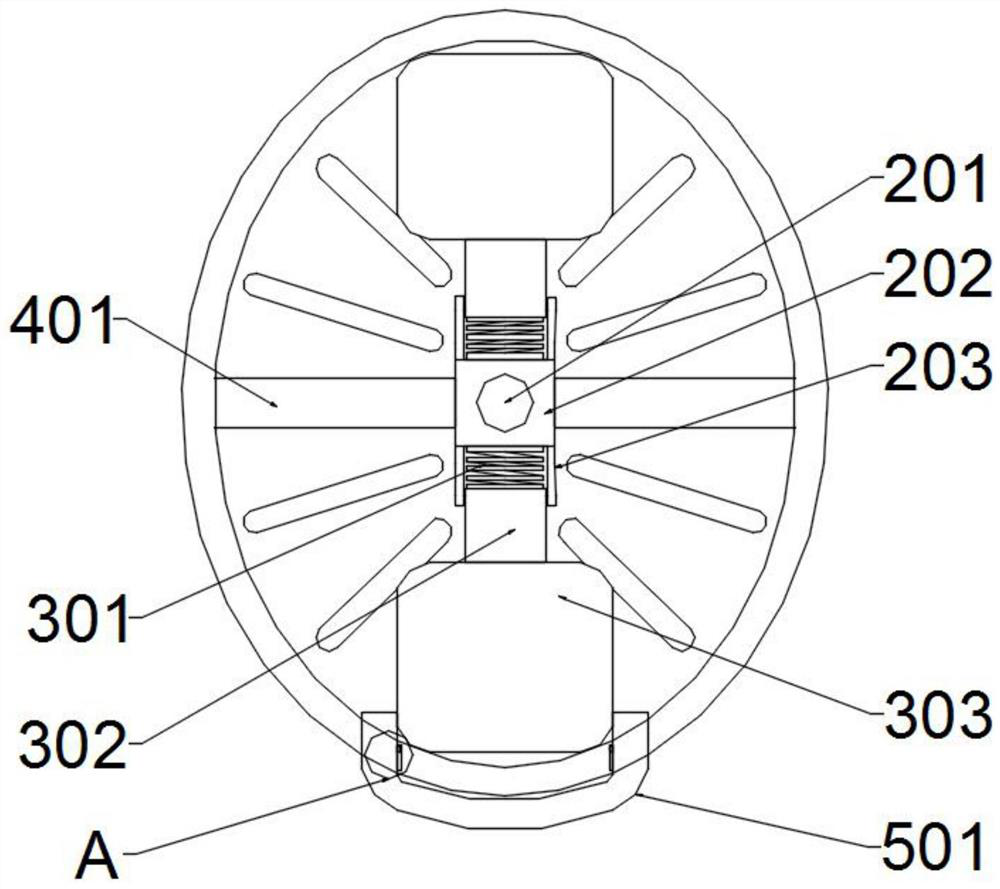

[0032] Example: such as Figure 1-10 As shown, a high-efficiency production workbench for internal and external partitions of a CNC gantry machining center includes a support component, a fixed component, a workbench component, an isolation component, and a positioning component. There is a fixed component in the center of the support component, which plays the role of supporting and fixing other parts. A workbench component is arranged on the side of the fixed component, and the workbench component plays the role of supporting the workpiece processed by the outside. The components play the role of isolating the device into two parts, the inside and the outside. One end of the limit ring 102 is provided with a positioning component, and the positioning component plays the role of positioning the workbench components.

[0033] The support assembly includes a fixed base plate 101, a limit ring 102, and a drainage groove 103. The fixed base plate 101 is located at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com