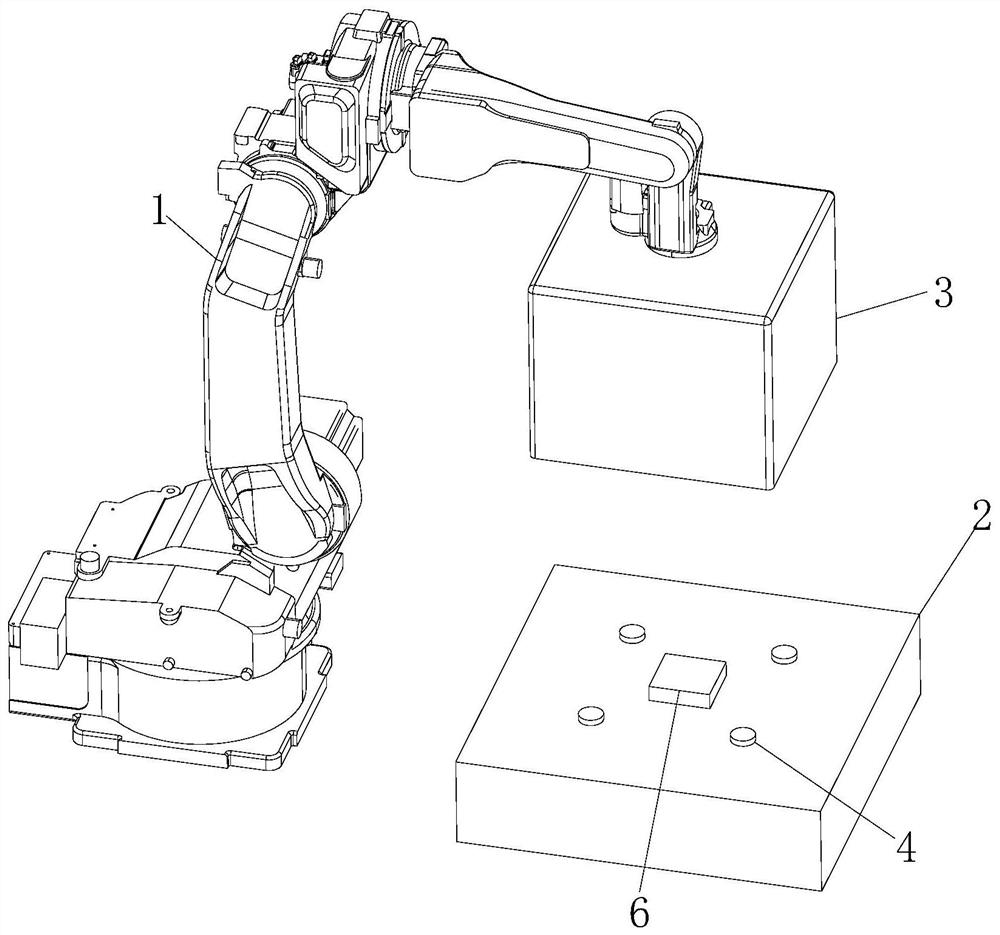

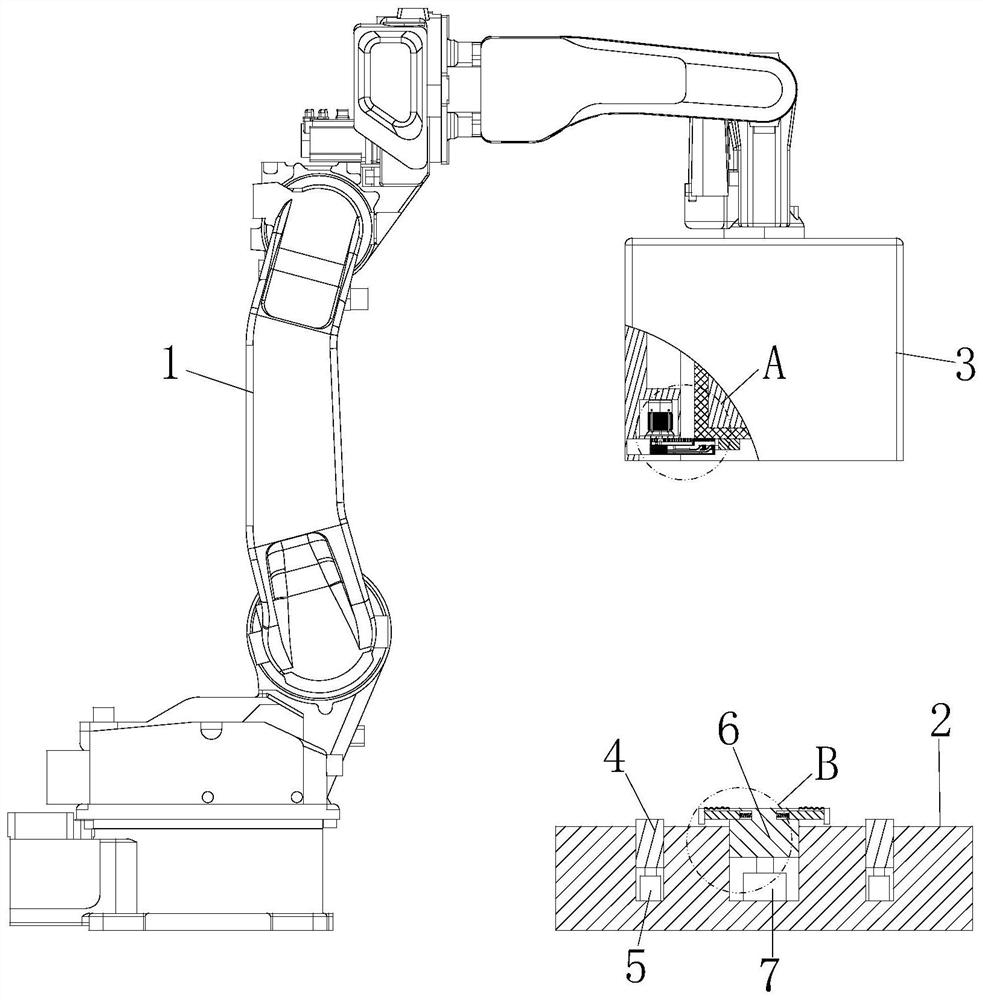

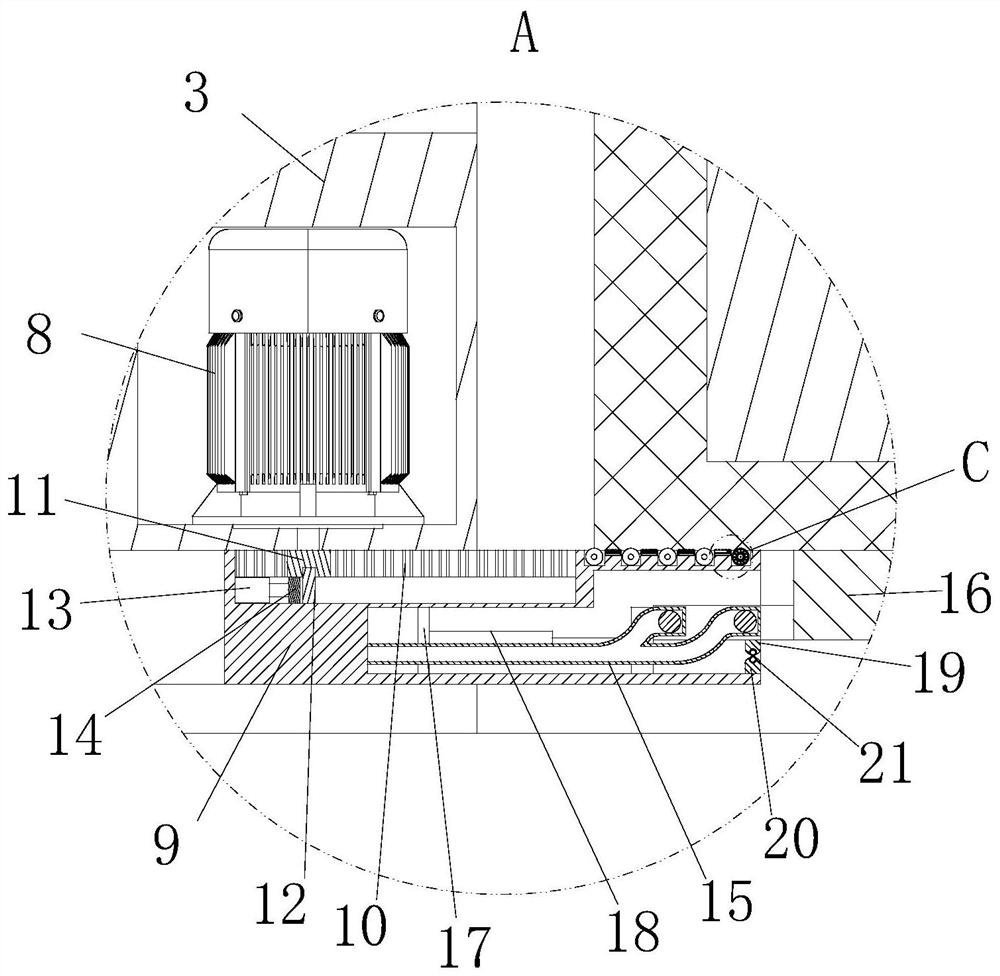

[0007] The technical solution adopted by the present invention to solve the technical problems is: a large data-based automatic reclaiming anti-skid manipulator according to the present invention, including a manipulator body, a backing plate and a fixing box; the top of the manipulator body is fixedly connected with a fixed box; the bottom of the fixed box is provided with a backing plate; the top surface of the backing plate is provided with evenly arranged first guide grooves directly below the fixed box; the inside of the first guide groove is slidingly connected with a first guide block; the first guide block is fixedly connected with the first telescopic rod between the groove bottom corresponding to the first guide groove; the top surface of the backing plate is provided with a second guide groove in the middle of the backing plate; the first The inside of the two guide grooves is slidingly connected with a second guide block; a second telescopic rod is fixedly connected between the second guide block and the bottom of the second guide groove, and the second telescopic rod and the first telescopic rod are connected to each other. Connected; the bottom surface of the fixed box is provided with a holding groove; the side wall of the fixed box is fixedly connected with a motor; the side wall of the fixed box is provided with a chute near the bottom surface of the fixed box; The first support plate is slidingly connected inside; the surface of the first support plate is fixedly connected with a tooth plate; the output shaft of the motor is fixedly connected with a gear, and the gear is meshed with the tooth plate; during work, the industrial In the production process, in order to improve work efficiency, more and more manipulators are used, especially for the handling of product packaging. In the prior art, the manipulator basically directly clamps the product or the side of the product packaging box. wall to realize the handling of the packaging box. For products with low

surface strength and

transshipment items such as packaging boxes, under the action of the gravity of the transfer item itself, a large

shear force will be generated between the manipulator and the transfer item, which is very difficult. It is easy to cause the surface of the transfer object to be squeezed or scratched. At the same time, when the transfer object is heavy, it is easy to

slip and fall, which increases the risk of transfer. In order to solve this problem, in the prior art, a simple Set up a support structure, but because the support structure cannot be directly inserted into the bottom of the

transporter, it is necessary to clamp the

transporter first, and then support it through the support structure, but for some fragile transporters, the early clamping is also necessary. It is easy to cause damage, and for easily deformable transport objects, it is easy to have problems such as slipping in the early stage. Through the automatic retrieving anti-slip manipulator based on

big data of the present invention, when it is necessary to use the manipulator to transfer the transport objects , first of all, during production, it is necessary to place the product or packing box above the backing plate, such as direct packaging production above the backing plate, then start the manipulator body, and move the fixed box to the position directly above the backing plate through the manipulator body, and then Control the downward movement of the fixed box, and squeeze the first guide block, so that the first guide block is retracted into the corresponding first guide groove, and the first guide block will squeeze the corresponding first telescopic rod, so that the inside of the first telescopic rod The gas enters the inside of the second telescopic rod, and the second telescopic rod will drive the second guide block to

push out of the second guide groove to realize the lifting of the transfer object. At this time, start the motor again, and the rotation of the motor will drive the gear to rotate, and the gear will drive The tooth plate moves, and the tooth plate will then drive the first support plate to slide, so as to realize the sliding of the first support plate to the bottom position of the transfer object, and then to the Lift the fixed box, and then realize the transfer of the transfer object. When the transfer is to the designated point, the first support plate can be directly reset, and the transfer object can be exported from the inside of the fixed box. The invention effectively realizes the rapid transfer of the transfer object. The bottom is lifted directly, no need to clamp the transfer object, and there is no need to insert the support structure directly into the bottom of the transfer object, which avoids damage to the surface of the transfer object. At the same time, the bottom support and the protection of the fixed box avoid the transfer In the process of slipping and falling of objects and during the transfer process, there are problems such as falling due to the action of the backing plate, which improves the safety of transfer

Login to View More

Login to View More  Login to View More

Login to View More