Novel internal mixer for rubber production and rubber production process

A technology of production process and internal mixer, which is applied in the field of new internal mixer for rubber production and rubber production process, can solve the problems of environmental pollution, waste, easy to float out a large amount of rubber powder, etc., to ensure dust collection efficiency, reduce waste and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

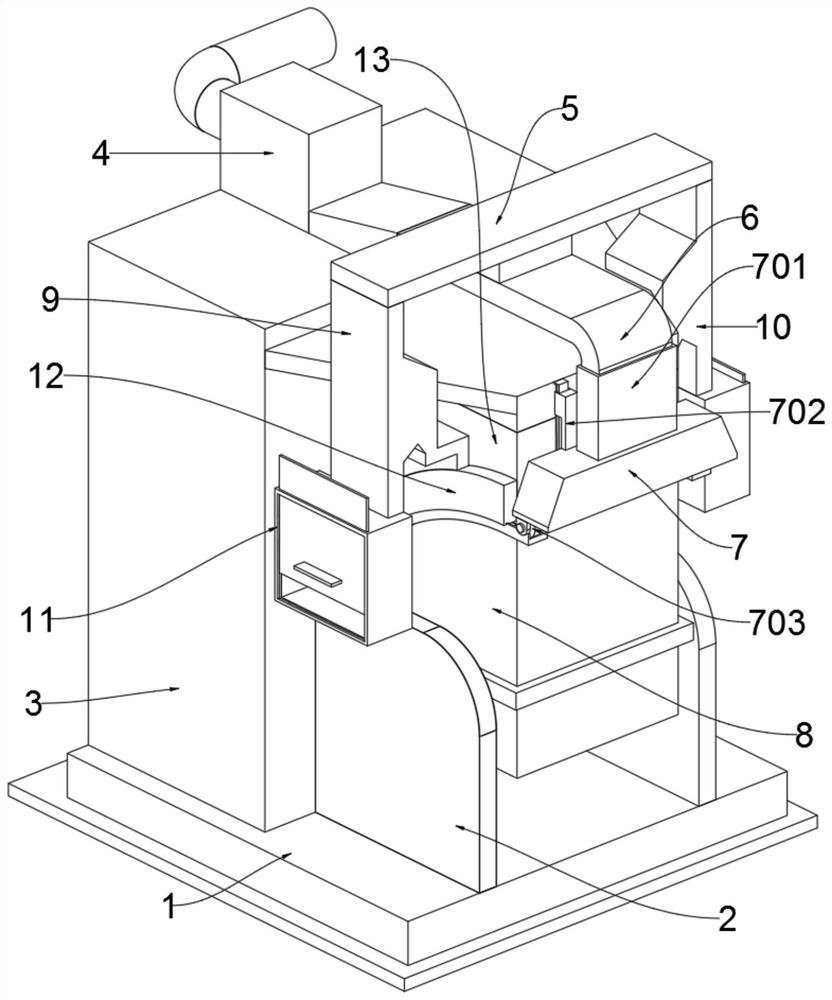

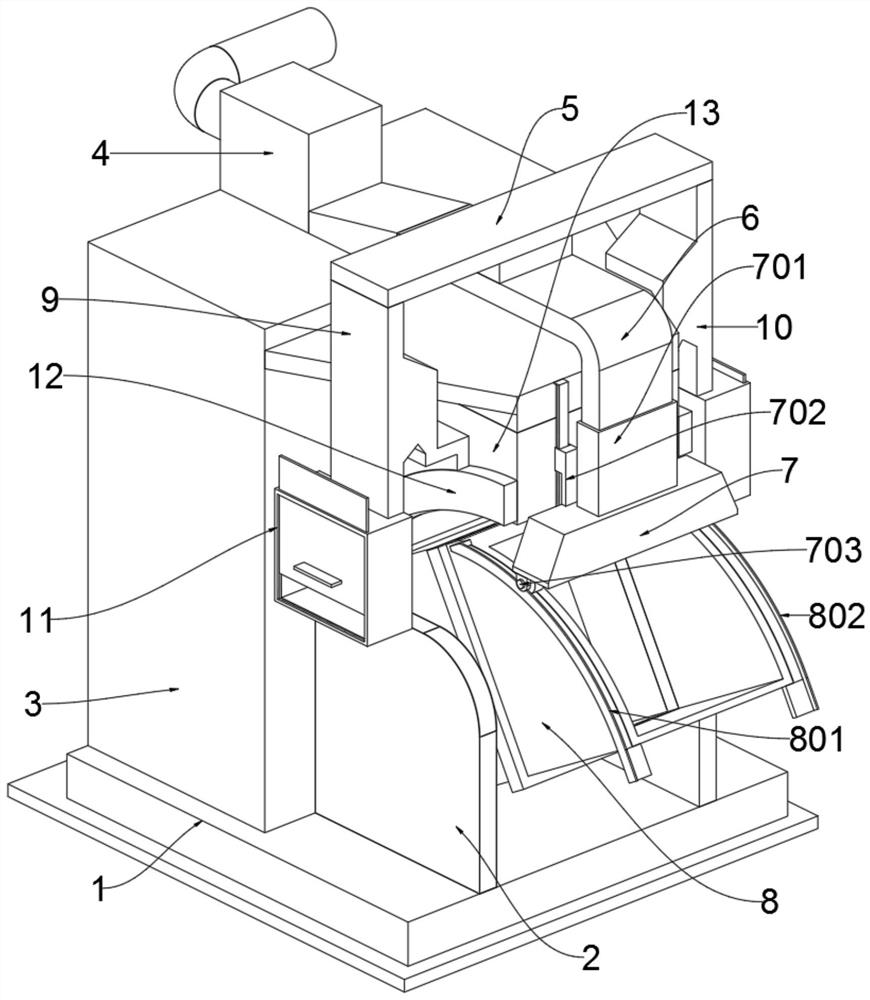

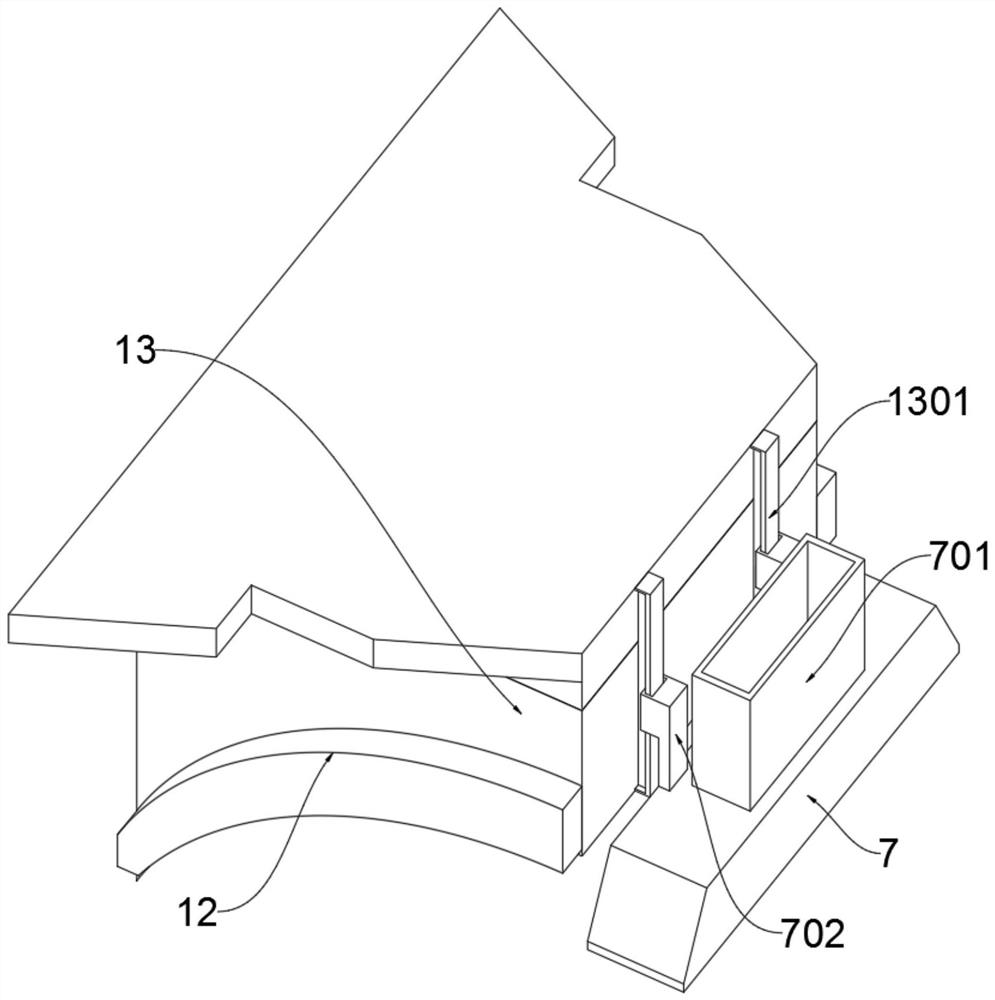

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides a new type internal mixer for rubber production, which includes a base 1, a dust suction device 4, a delivery pipe 5, a telescopic inner pipe 6, a lifting dust suction cover 7, a hopper 8, a left sedimentation cylinder 9, and a right sedimentation cylinder 10 , settling box 11, side suction cover 12, discharge upper cylinder 13; the upper surface of base 1 is provided with support plate 2, and the upper surface of base 1 is provided with internal mixer main body 3; It is fixedly connected above the main body 3 of the internal mixer; the end of the pipe body of the conveying pipe 5 is connected to the air inlet of the dust collection device 4 by welding; the end of the telescopic inner pipe 6 is fixedly connected to the other end of the conveying pipe 5 by welding; The top of the dust collection cover 7 is slidably connected to the outside of the other end of the telescopic inner pipe 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com