Classification method and system of intelligent garbage classification bin

A technology of garbage classification and classification method, applied in the field of classification methods and systems of intelligent garbage classification bins, can solve the problems of non-standard garbage classification and delivery, waste of renewable garbage resources, mixed garbage classification bins, etc., to save labor costs and Hardware cost, the effect of promoting urban environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

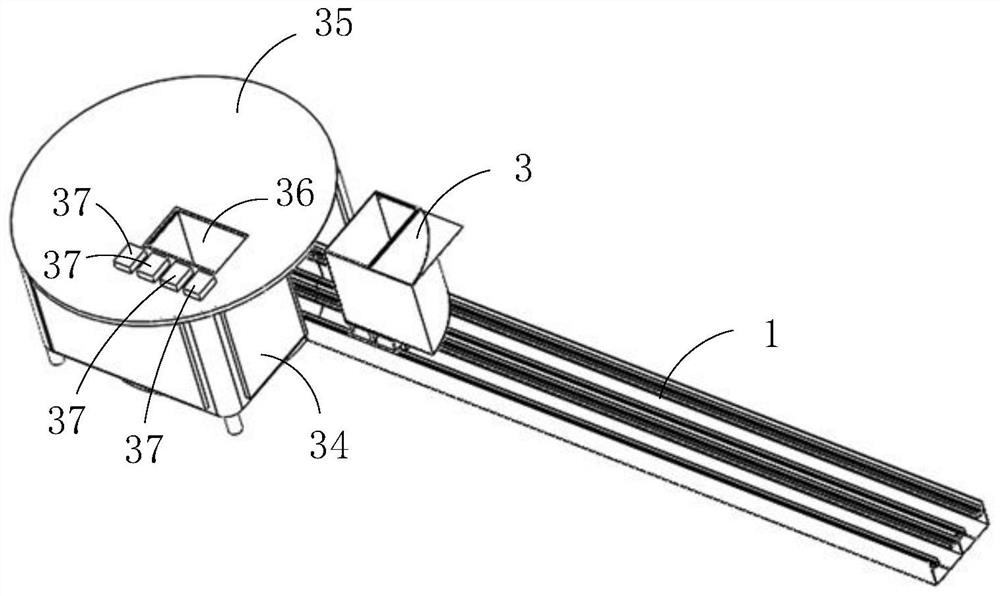

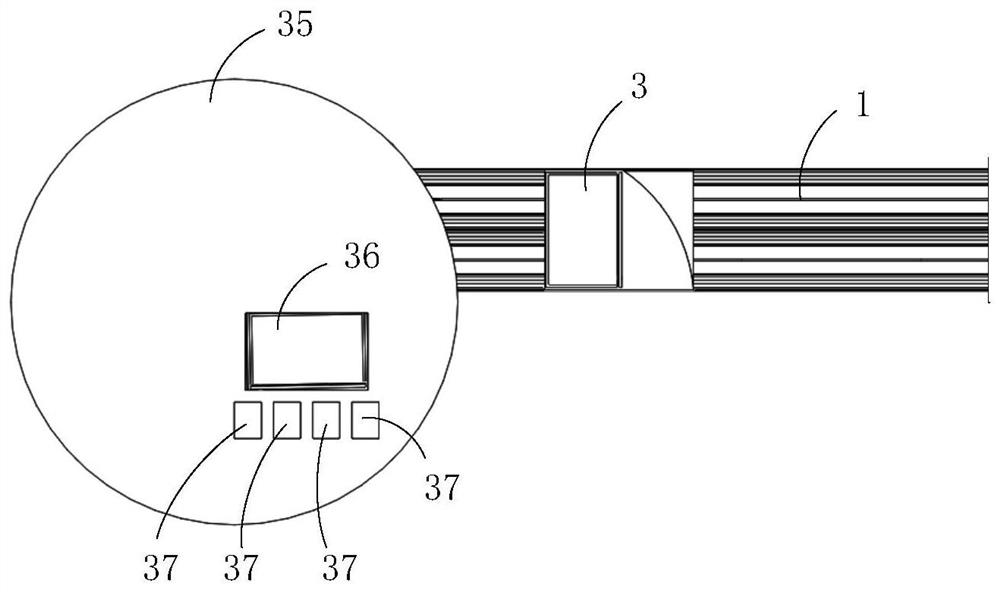

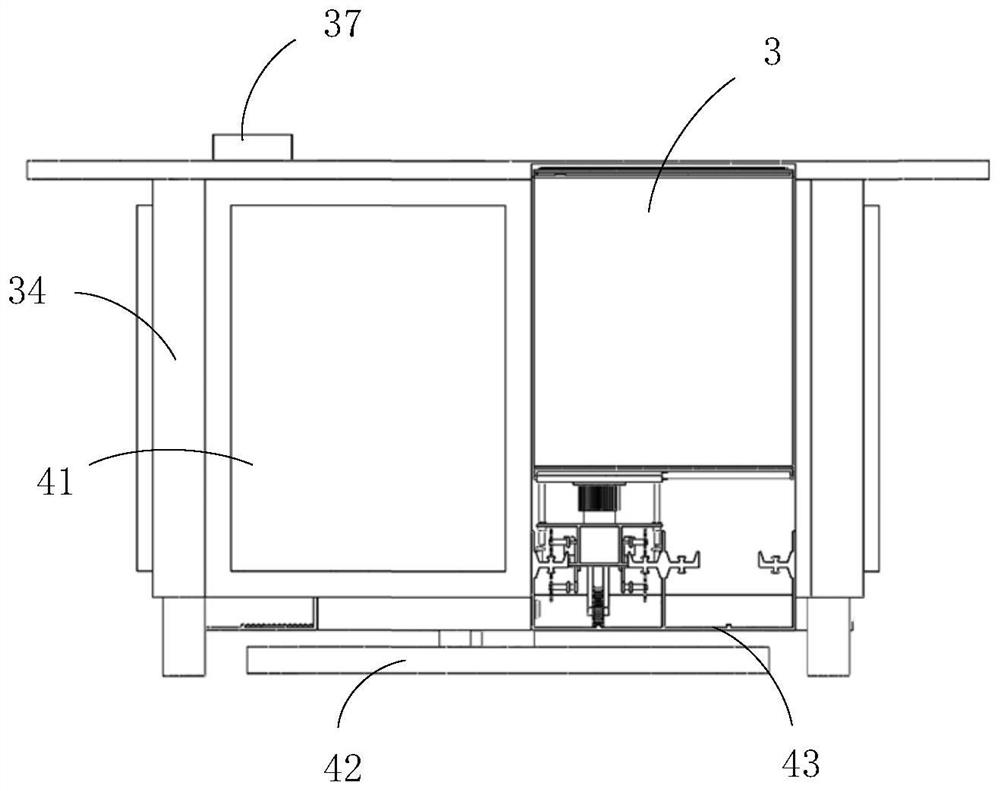

[0085] like Figure 1-20 As shown, this embodiment is a sorting method of an intelligent garbage sorting bin. First, the smart garbage sorting bin will be described here, so as to better understand the technical solution of the present application. This intelligent garbage sorting bucket includes several sorting boxes 34, a six-way track 1 docked with all sorting boxes 34, and several track trash can vats 5 arranged on the six-way track 1; mechanism, the rotating mechanism is provided with at least two track trash can kegs 3; the track trash can keg 3 and the track trash can big bucket 5 can travel along the six-way track 1 through the traveling wheel train 2 thereon, and the track Garbage can small bucket 3 can pour the sorted garbage in it in the track garbage can big bucket 5. That is, the upper ends of the track trash can keg 3 and the track trash can bucket 5 are equipped with a traveling wheel train 2, which can be installed on the six-way track 1 and move along the six...

Embodiment 2

[0116] In this embodiment, on the basis of Embodiment 1, the user throws the classified garbage into the track trash can keg 3 of the corresponding garbage classification category, and also includes the following steps in its step 3:

[0117] 3.1: When the garbage disposal opening 13 of the track trash can keg 3 overlaps with the classified garbage disposal slot 36 of the sorting box 34, the central control system sends a door-opening command to the keg controller on the track trash can keg 3 to control The garbage disposal port 13 of the track trash can small bucket 3 is opened, and the delay module starts timing, and the user throws classified garbage into the track trash can small bucket 3;

[0118] 3.2: The infrared sensing module detects whether there is garbage thrown into the track trash can 3 within the set time period; if yes, control the garbage disposal port 13 of the track trash can 3 to continue to open for a time period, and repeat the execution Step 3.2; No, the...

Embodiment 3

[0120] Present embodiment is on the basis of embodiment 1, and it also comprises the following steps after step 7:

[0121] Step 7.1: Real-time detection of whether the sorted garbage in each orbital garbage bin 5 has reached its load limit. When the load limit is reached, the bucket controller on the track garbage bin 5 sends a bucket full signal to the central control system, and the central control system Analyze the position of the garbage sorting recycling station or garbage treatment plant closest to the rail trash bin 5, and send a control drive walking command to the bucket controller, and the bucket controller controls the rail trash bin 5 to drive to the nearest garbage classification Recycle bin or garbage disposal plant. Here, when the bucket radar probe on the track garbage can bucket 5 detects that the garbage is full, or when the bucket load sensor on the track garbage bucket bucket 5 detects that the weight of the garbage reaches the upper limit, it means that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com