Two-component spinneret plate

A spinneret, two-component technology, used in the field of spinning, can solve the problems of fluid turbulence, unstable pressure, fusion of skin and core materials, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved objects and effects of the present invention in detail, the following detailed description is given in conjunction with the embodiments and the accompanying drawings.

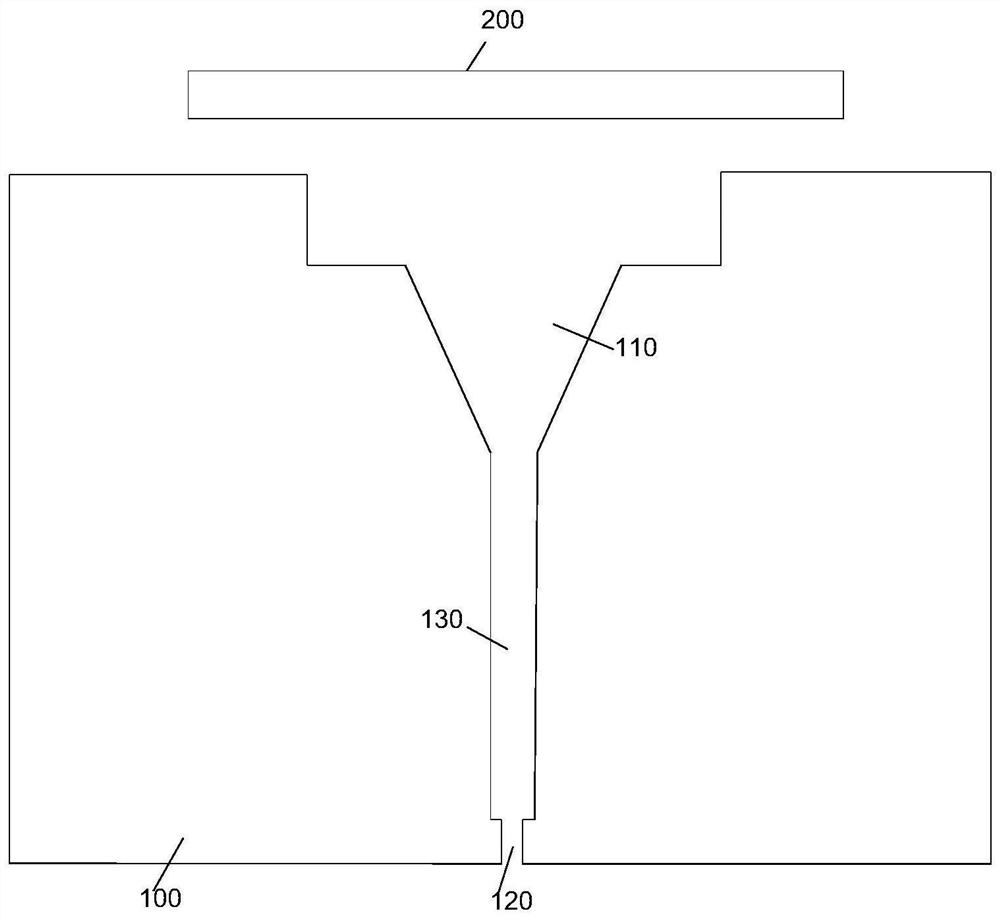

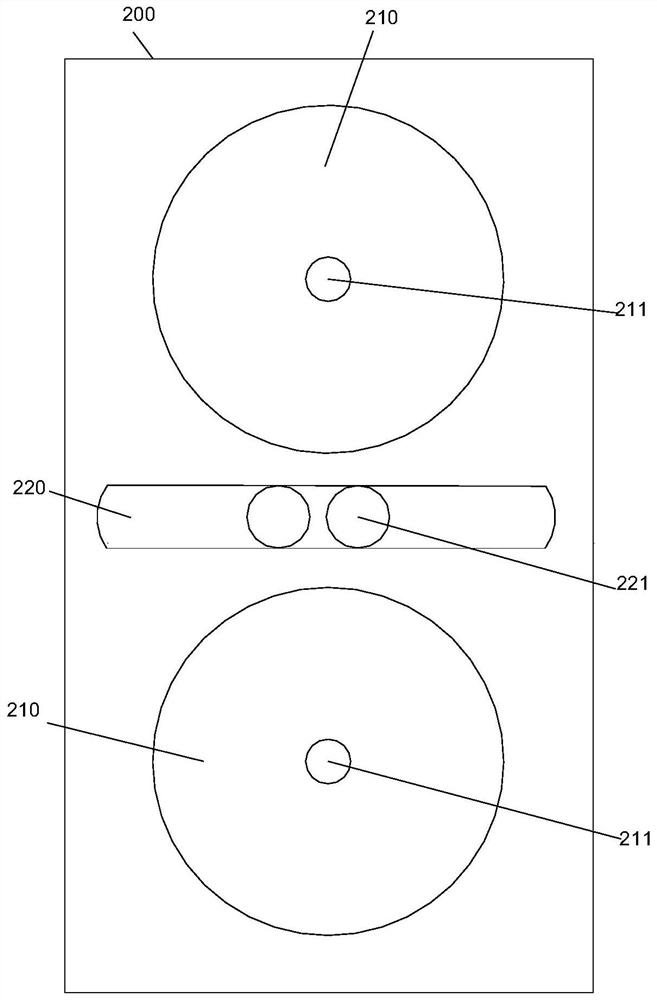

[0021] see Figure 1 to Figure 2 , a two-component spinneret, the spinneret 100 is installed in the spinneret assembly, the function of the spinneret assembly is mainly to divide the melt metered from the spinning pump into thin streams of specific shape and cross-section, and the spinneret assembly It also includes a filter plate and a distribution plate 200. A distribution plate 200 is arranged above the spinneret 100. The distribution plate 200 distributes the melt to the spinneret 100. A filter plate is arranged above the distribution plate 200 to prevent the melt from being blocked by impurities. Spinneret hole.

[0022] In this embodiment, the spinneret holes of the spinneret 100 are provided with guide holes 110 and micro h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap