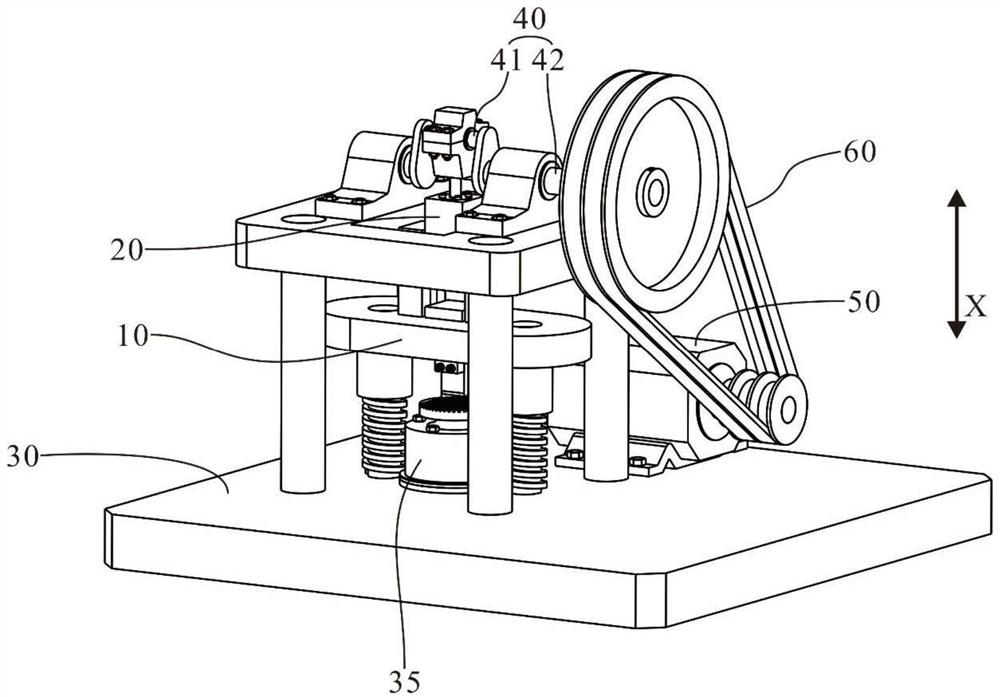

Impact fatigue test device

A test device and impact fatigue technology, applied in the direction of impact test, measurement device, machine/structural component testing, etc., can solve the problems of high cost, low cycle frequency, large space occupied by the test device, etc. Impact parameters, easily adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

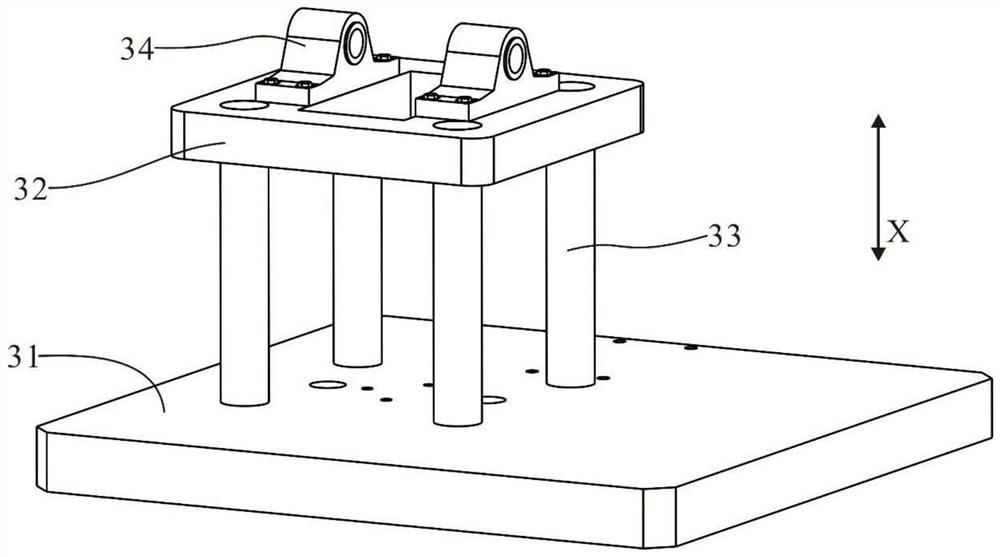

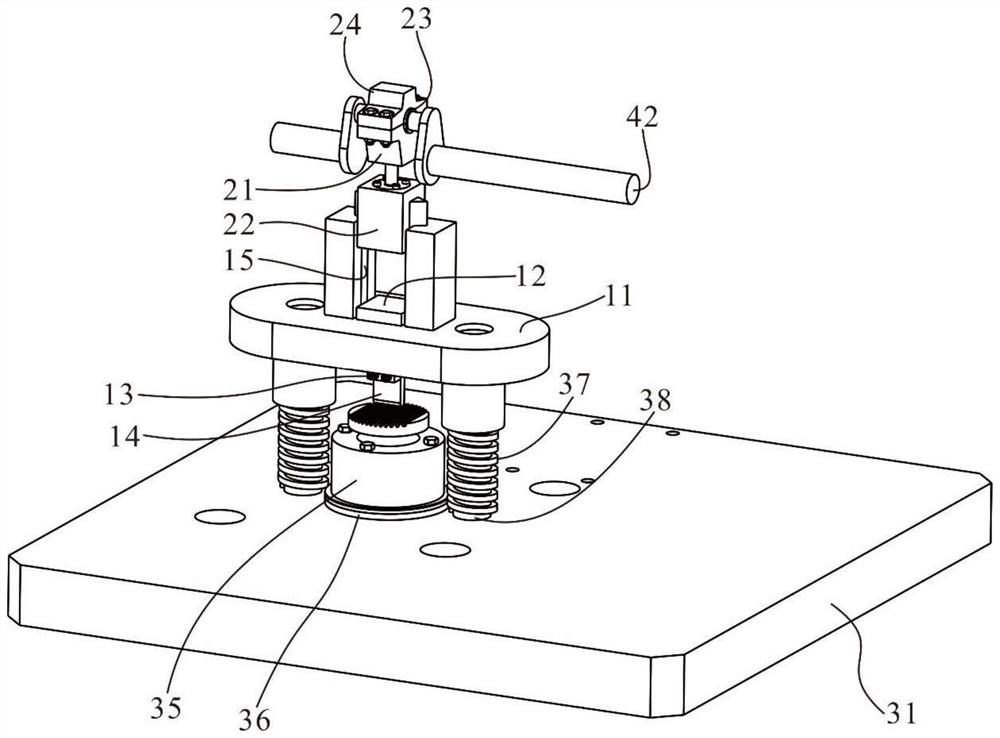

Method used

Image

Examples

Embodiment

[0088] A clutch manufacturer needs to use Cr as the material in the sprag clutch 7 C 3 The coating (the substrate is bearing steel) is tested for impact fatigue resistance. The thickness of the coating is about 10 μm, and the required number of impact fatigue cycles needs to reach 10 5 more than times. The test device needs to meet the actual requirements of adjustable load range and impact energy, high efficiency and short test period. Select n=1400r / min, l 1 = 20mm, l 2 =145mm, r 1 = 30mm, r 2 =150mm, at this time the impact frequency is 4.65Hz, and it takes about 6 hours to complete a fatigue test. The thickness of the gasket can be adjusted between 0 and 20mm, and the impact speed can be adjusted between 0 and 0.5m / s; among them, Figure 6 It is a graph of the motion law of the slider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com