Highway tunnel jet fan supporting structure bearing capacity detection device and method

A technology of jet fan and support structure, which is applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc. Insufficient connection strength of embedded boards, etc., to achieve the effect of improving quality, improving stability and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following is attached Figure 1-4 The application is described in further detail.

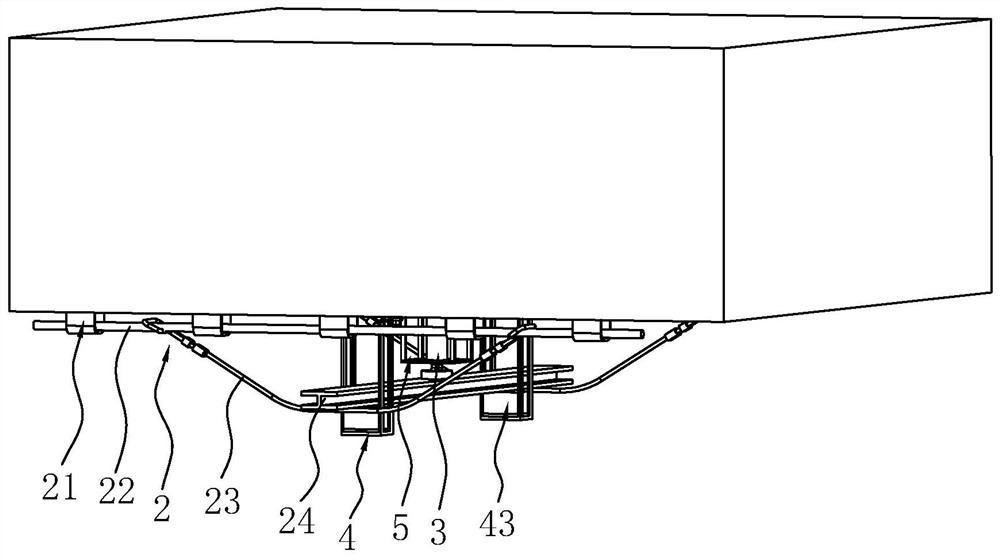

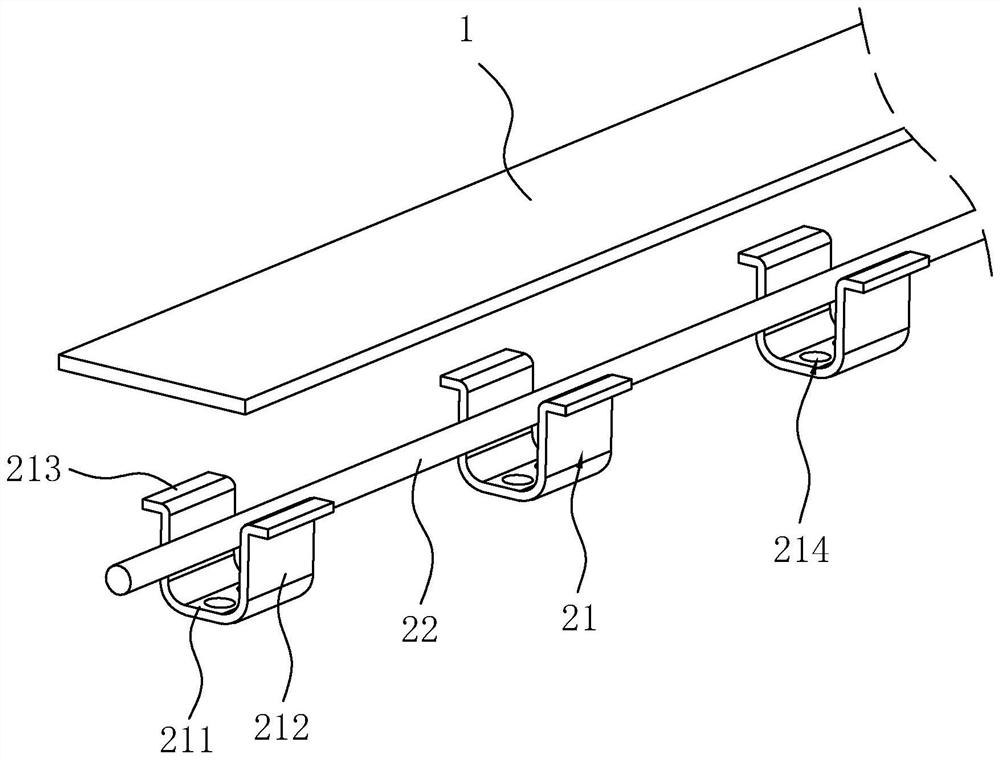

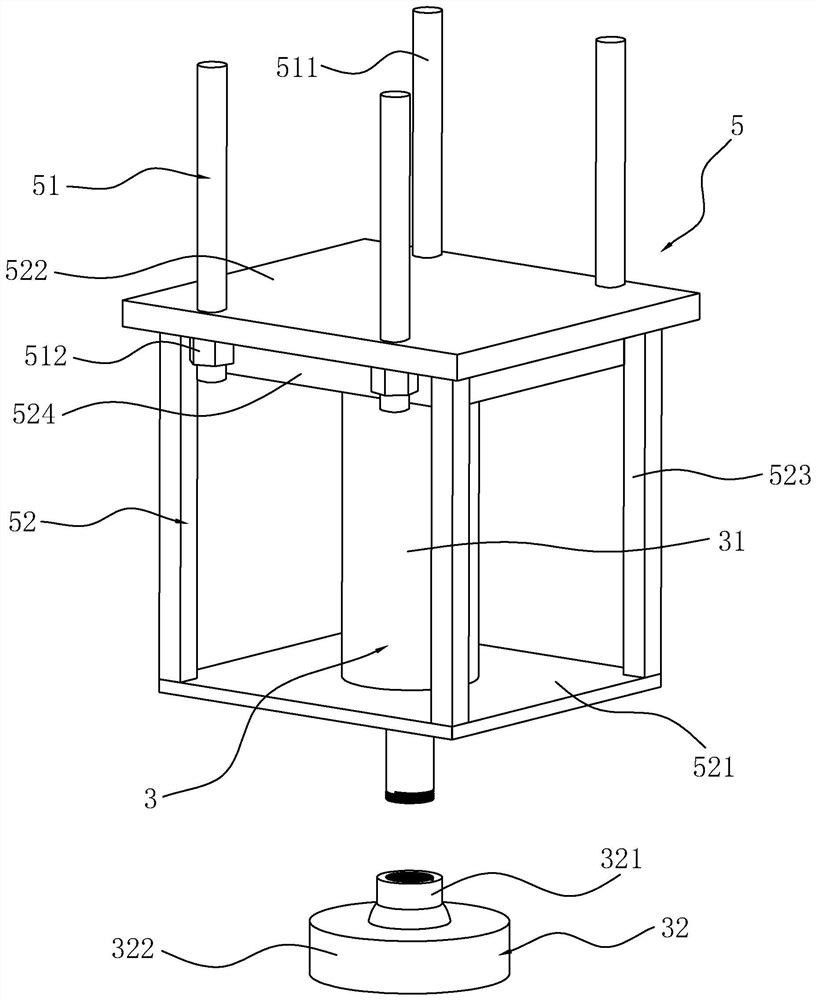

[0054] The embodiment of the application discloses a bearing capacity detection device for a jet fan support structure of a road tunnel. refer to figure 1 and figure 2 , the detection device includes a reaction force assembly 2, a pressurization assembly 3, a first protection assembly 4 and a second protection assembly 5, the reaction force assembly 2 is fixed on the pre-embedded steel plate 1 on the roof wall of the tunnel, and the pressure assembly 3 is used for The reaction force component 2 applies pressure, the first protection component 4 is used for protecting the reaction force component 2 , and the second protection component 5 is used for protecting the pressurizing component 3 .

[0055] Such as figure 1 and figure 2 As shown, the reaction force assembly 2 includes several connectors 21, support rods 22, steel wire ropes 23 and beams 24, and several connectors 21 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com