Lower clamping plate structure for loudspeaker

A loudspeaker and splint technology, applied in the field of loudspeakers, can solve the problems of single heat dissipation, inability to conduct more effective heat dissipation, poor heat dissipation, etc., and achieve the effect of accelerated cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

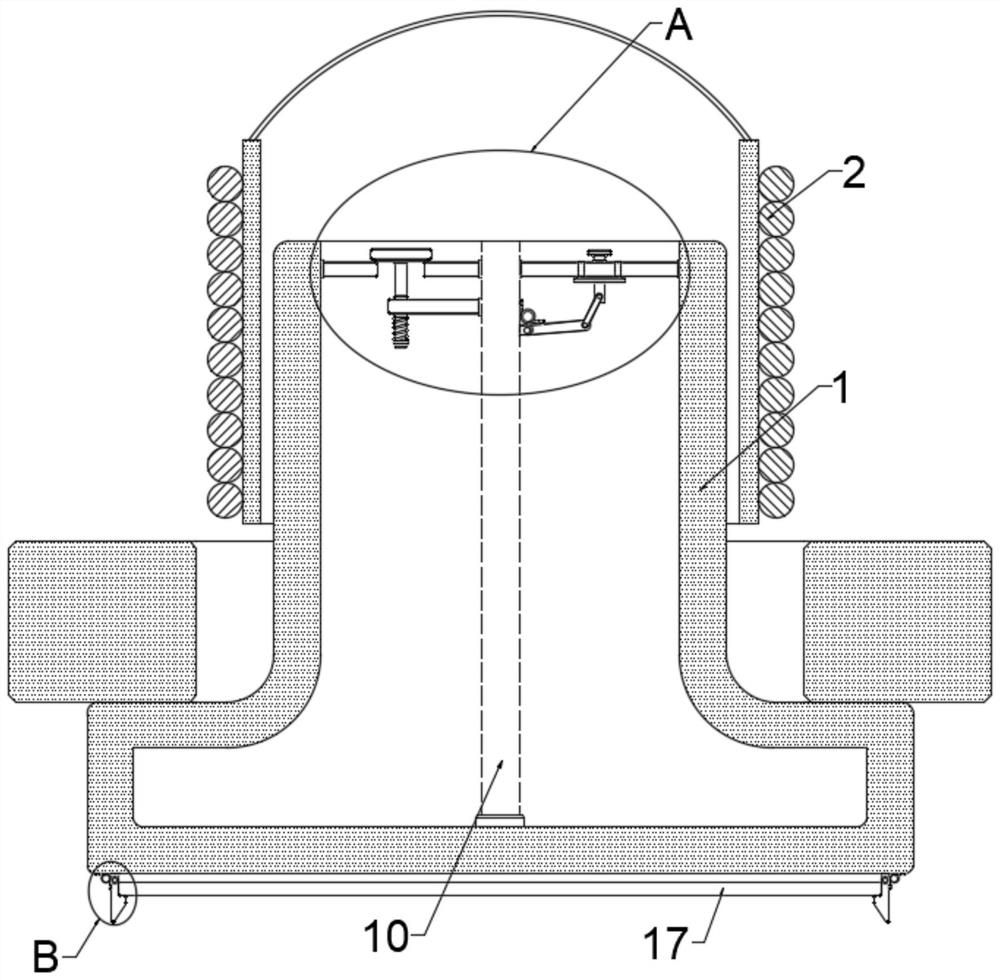

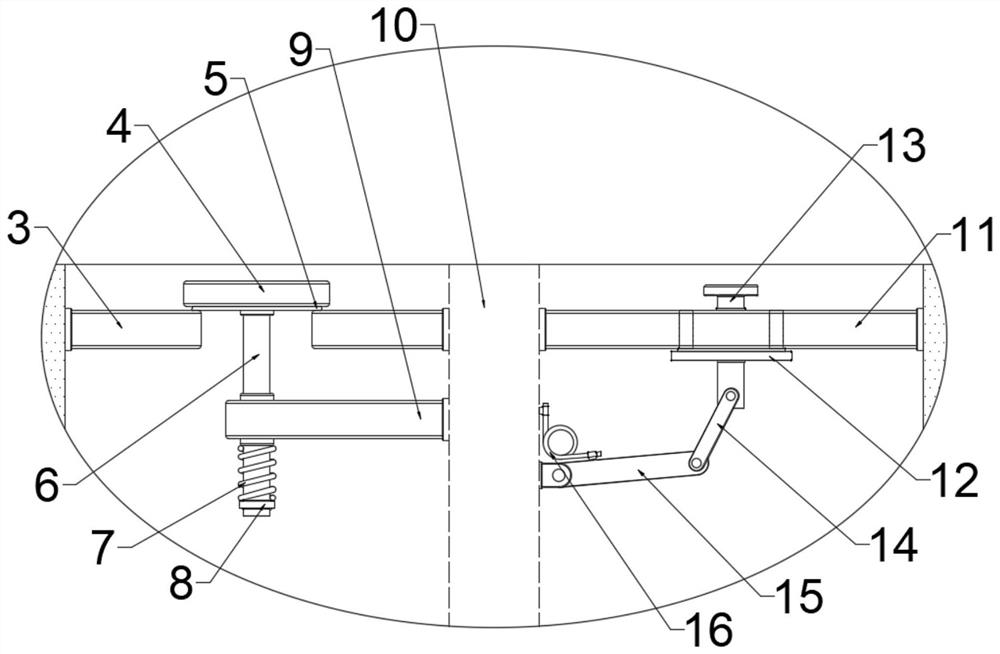

[0027] Embodiment: a kind of lower splint structure for loudspeaker, such as Figure 1-Figure 4 As shown, the speaker is inserted into the voice coil 2 with a lower splint structure and used to fix the permanent magnet, including:

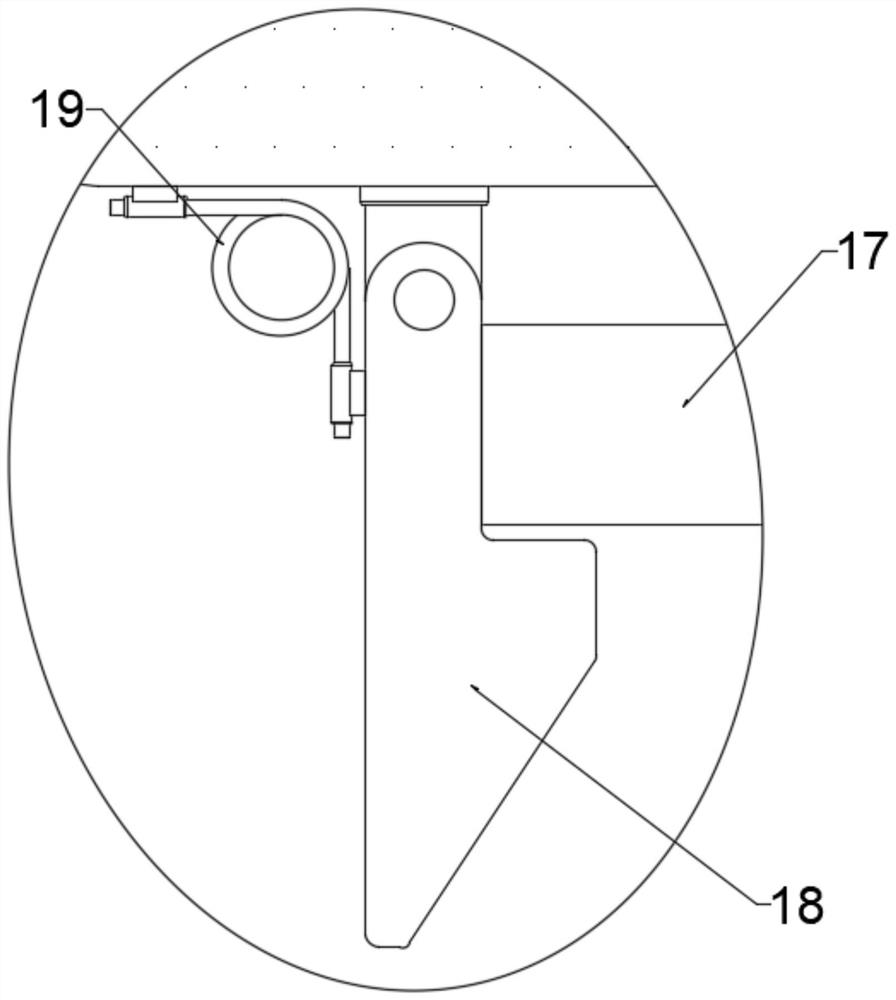

[0028] The lower splint 1, the lower splint 1 is movably connected with the voice coil 2, the lower splint 1 is internally connected and fixedly installed with a sealing plate 10, and the sealing plate 10 divides the lower splint 1 into two independent and conduction chamber;

[0029] an air intake mechanism, the air intake mechanism is arranged in one of the chambers and is used to suck the outside air into the space formed between the voice coil 2 and the lower splint 1 when the voice coil 2 vibrates upwards Inside;

[0030] an exhaust mechanism, the exhaust mechanism is arranged in the other chamber so that when the voice coil 2 vibrates downward, the hot air in the space formed between the voice coil 2 and the lower splint 1 is discharged;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com