Camera module

A technology for camera modules and circuit boards, applied in instruments, televisions, lenses, etc., can solve problems such as increased power consumption, eccentricity or inclination, complex structures, etc., and achieve the effects of increasing frictional torque, reducing friction, and improving control characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

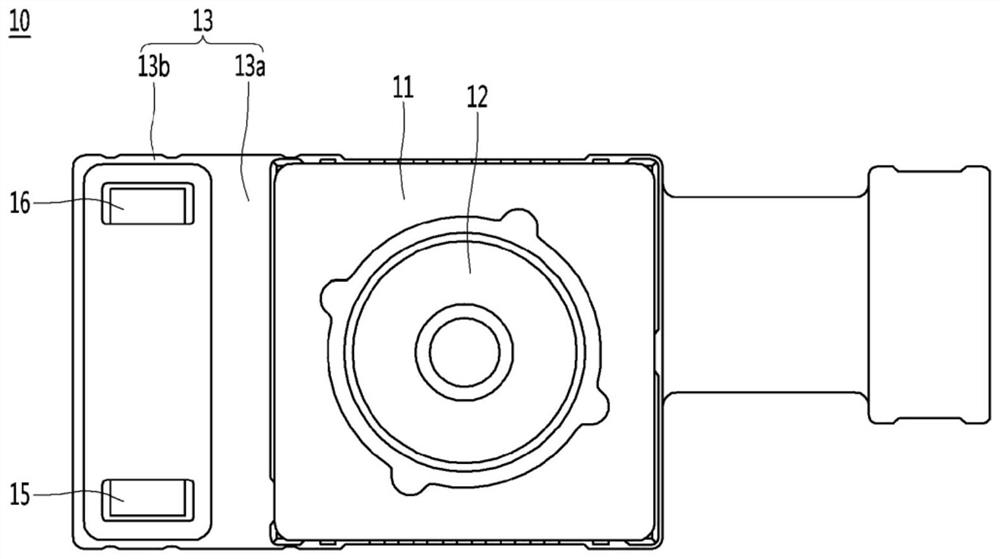

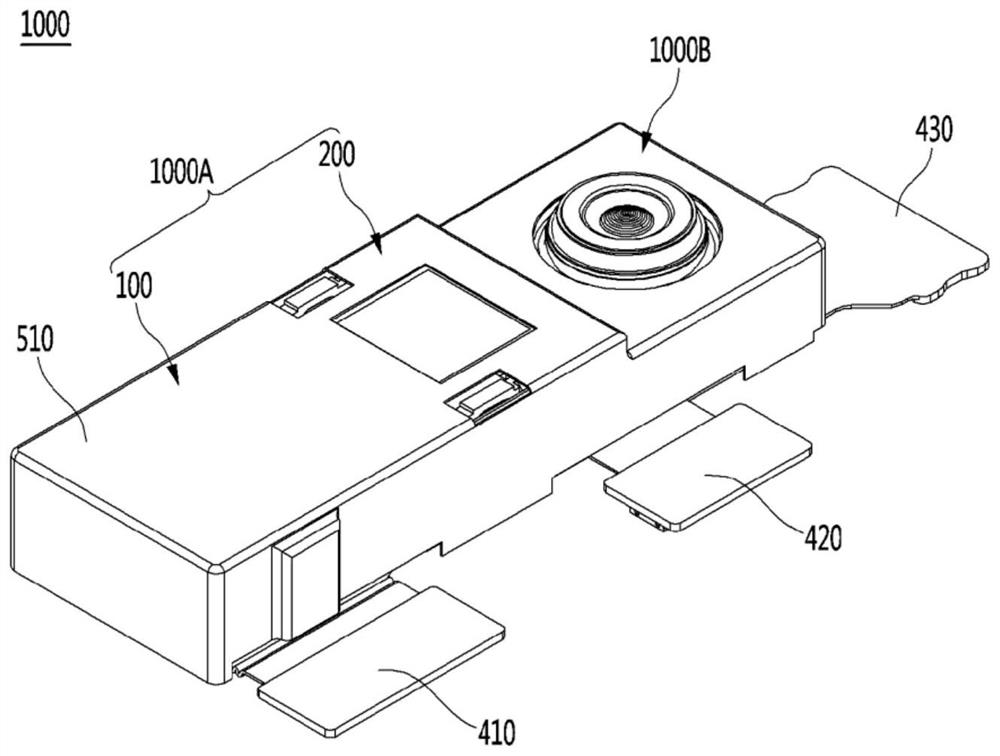

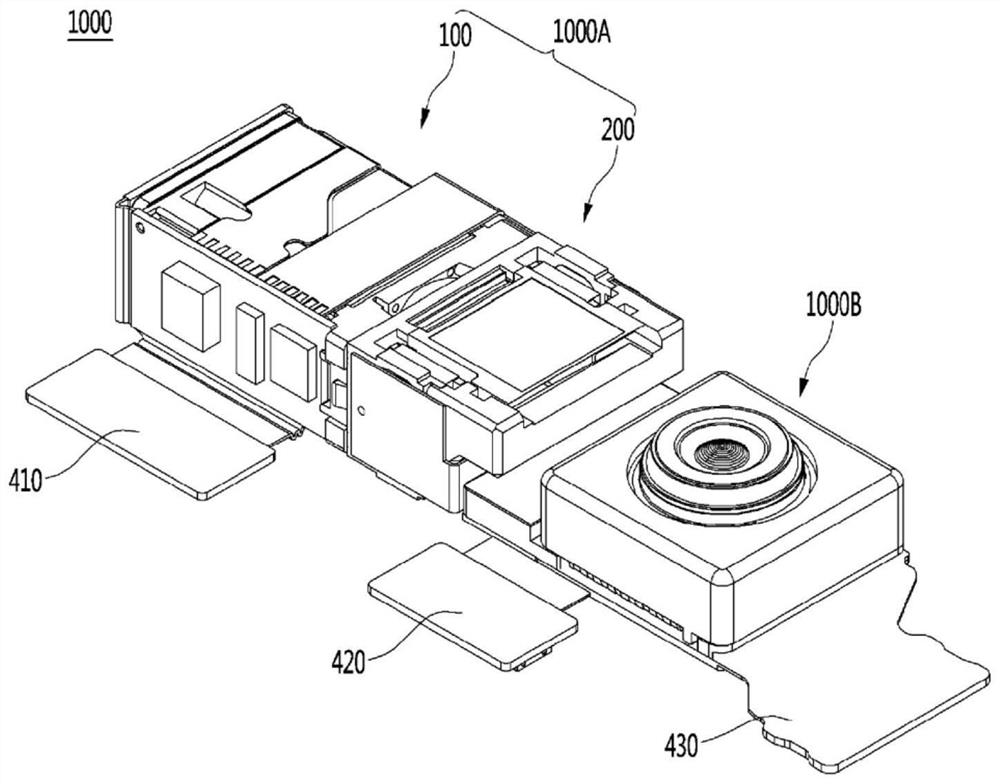

[0148] figure 2 is a perspective view showing the camera module 1000 of this embodiment, Figure 3a yes figure 2 A perspective view of the camera module 1000 of the illustrated embodiment with the shielding cover 510 removed, and Figure 3b yes Figure 3a A plan view of the camera module 1000 of the illustrated embodiment.

[0149] refer to figure 2 , the camera module 1000 of this embodiment may include a single camera module or a plurality of camera modules. For example, this embodiment may include a first camera module 1000A and a second camera module 1000B. The first camera module 1000A and the second camera module 1000B may be covered by a predetermined shield cover 510 .

[0150] refer to together figure 2 , Figure 3a and Figure 3b , in an embodiment, the first camera module 1000A may include a single actuator or a plurality of actuators. For example, the first camera module 1000A according to this embodiment may include the first actuator 100 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com