Rubber rain shoes with matting effect based on rubber decal cold transfer process and manufacturing method

A manufacturing method, technology of cold transfer, applied in crafts, shoe uppers, footwear, etc. for producing decorative surface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

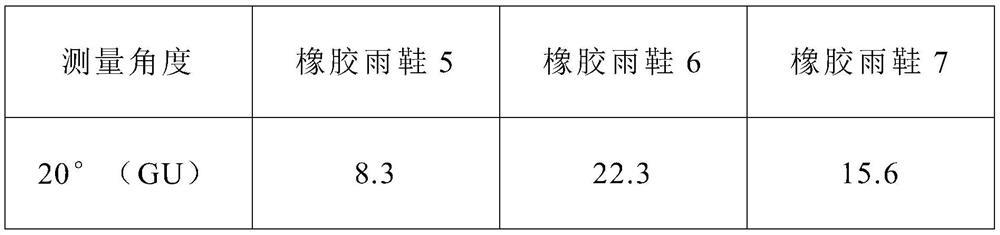

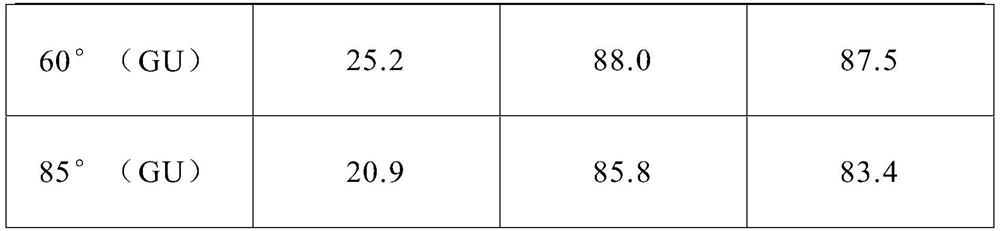

Examples

Embodiment 1

[0027] This embodiment provides a method for making rubber rain boots with matting effect based on the cold transfer process of rubber appliques, comprising the following steps:

[0028] Step 1: adding neoprene resin and additives to a masticating machine for masticating, and obtaining raw rubber sheets after masticating is completed;

[0029] Step 2: Print the required pattern on the printing film;

[0030] Step 3: transfer the pattern on the printing film to the raw rubber sheet prepared in step 1, and use the raw rubber sheet to make rain boots;

[0031] Step 4: Spray the matting agent on the surface of the rubber rain boots prepared in step 3 to obtain the finished matting rain boots. The amount of matting agent sprayed is 4% of the total mass of neoprene resin and additives.

[0032] Wherein, the mass fraction that neoprene resin adds is 40 parts, and described auxiliary agent comprises the nitrile rubber that mass fraction is respectively 30 parts, the polyvinyl chlorid...

Embodiment 2

[0035] This embodiment provides a method for making rubber rain boots with matting effect based on the cold transfer process of rubber appliques, comprising the following steps:

[0036] Step 1: adding neoprene resin and additives to a masticating machine for masticating, and obtaining raw rubber sheets after masticating is completed;

[0037] Step 2: Print the required pattern on the printing film;

[0038] Step 3: transfer the pattern on the printing film to the raw rubber sheet prepared in step 1, and use the raw rubber sheet to make rain boots;

[0039] Step 4: Spray a matting agent on the surface of the rubber rain boots prepared in Step 3 to obtain a finished matting rain boot. The amount of the matting agent sprayed is 0.1% of the total mass of the neoprene resin and additives.

[0040] Wherein, the mass fraction that neoprene resin adds is 50 parts, and described auxiliary agent comprises the nitrile rubber that mass fraction is respectively 20 parts, the polyvinyl ch...

Embodiment 3

[0043] This embodiment provides a method for making rubber rain boots with matting effect based on the cold transfer process of rubber appliques, comprising the following steps:

[0044] Step 1: adding neoprene resin and additives to a masticating machine for masticating, and obtaining raw rubber sheets after masticating is completed;

[0045] Step 2: Print the required pattern on the printing film;

[0046] Step 3: transfer the pattern on the printing film to the raw rubber sheet prepared in step 1, and use the raw rubber sheet to make rain boots;

[0047] Step 4: Spray the matting agent on the surface of the rubber rain boots prepared in step 3 to obtain the finished matting rain boots. The amount of matting agent sprayed is 2% of the total mass of neoprene resin and additives.

[0048] Wherein, the mass fraction that neoprene resin adds is 44 parts, and described auxiliary agent comprises the nitrile rubber that mass fraction is respectively 26 parts, the polyvinyl chlorid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com