Food processor with detachable crushing cutter assembly

A technology of a food processor and a crushing knife, which is applied in the field of food processing, can solve problems such as potential safety hazards, unreliable sealing of the crushing chamber, and easy leakage of the crushing chamber slurry, and achieve the effects of simplifying the positioning structure, improving reliability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

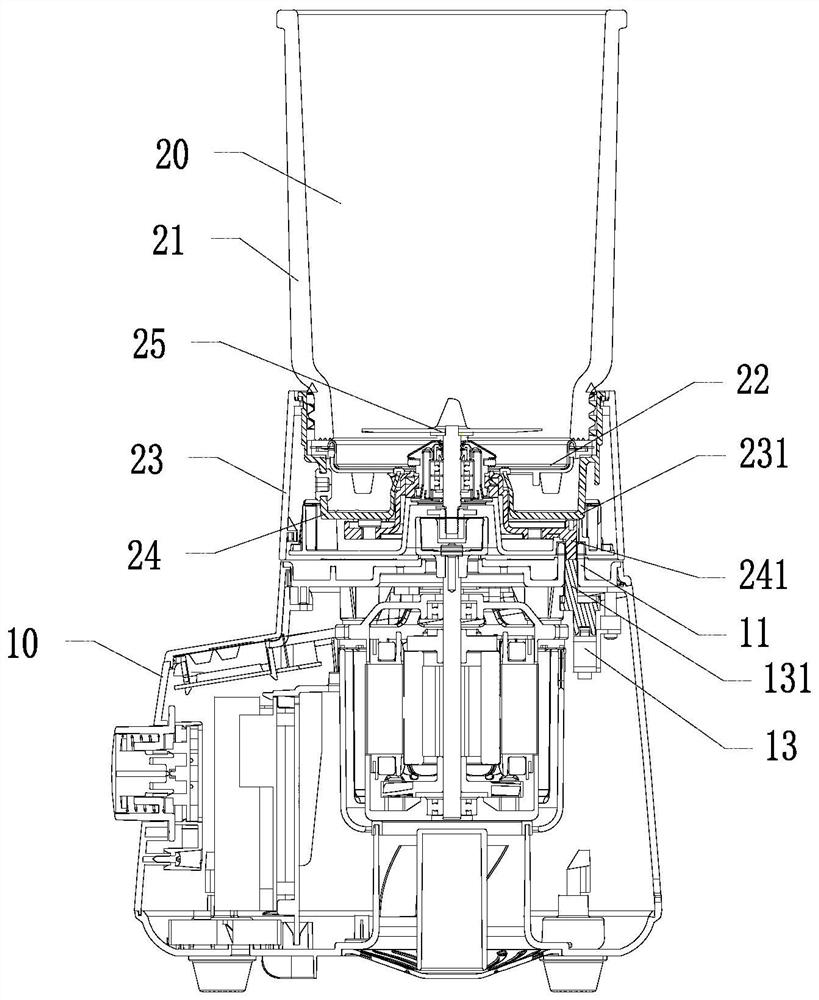

[0044] like Figure 1-Figure 8 As shown, the present invention provides a food processor with a detachable crushing knife assembly, including a main machine 10 and a stirring cup 20 installed on the main machine 10, the stirring cup 20 includes a cup body, and a crushing knife assembly 25 detachably connected to the cup body And the cup holder 23 installed below the cup body, the cup holder 23 is rotatably installed with a rotating bracket 24, the crushing knife assembly 25 penetrates the cup body and locks with the rotating bracket 24, the rotating bracket 24 is provided with an upper positioning structure 241, and the host 10 is provided with The lower positioning structure 11, the rotating bracket 24 rotates the preset stroke to lock the crushing knife assembly 25 and the rotating bracket 24 so that the upper positioning structure 241 is opposite to the lower positioning structure 11 to match the mixing cup 20 with the main machine 10, and the rotation of the rotating bracke...

Embodiment 2

[0057] The difference between the present embodiment and the first embodiment is that the upper positioning structure is a shield provided on the rotating bracket, and the lower positioning structure is a lower coupler on the host.

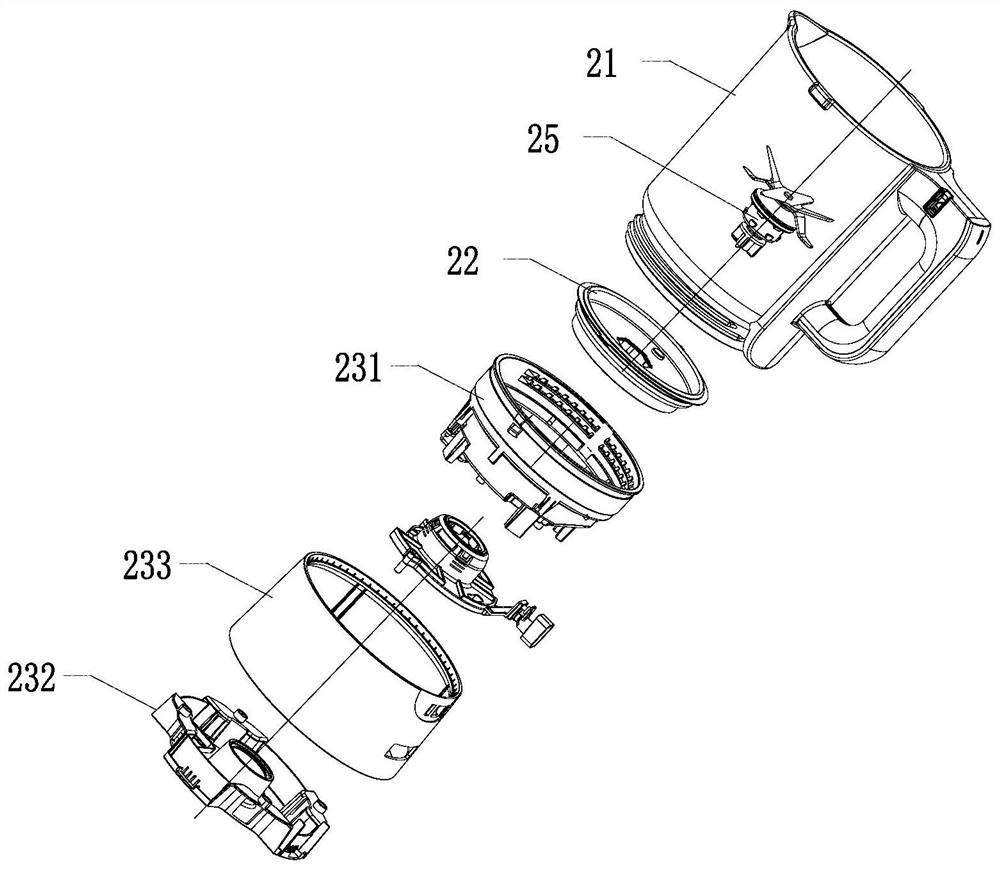

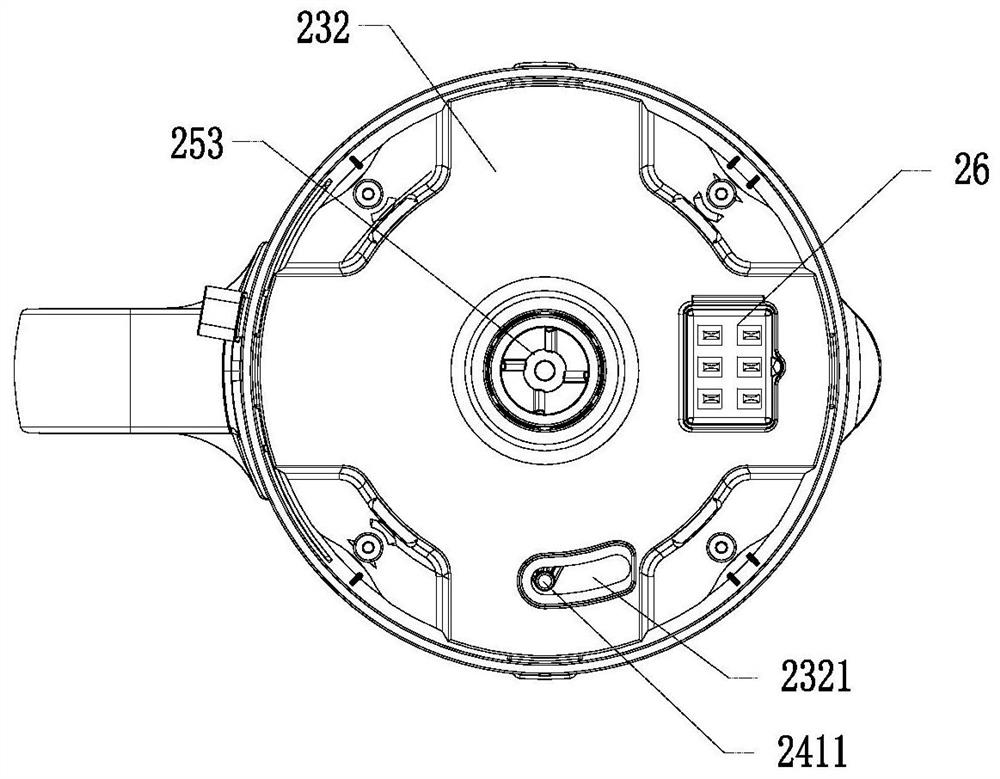

[0058] In this example, if Figure 9-Figure 11As shown, there is an upper coupler inside the cup holder, a lower coupler corresponding to the upper coupler 26 protrudes from the upper surface of the host, and a safety switch is provided inside the host. When the stirring cup is installed on the host, the upper coupler 26 and The lower coupler cooperates to realize electrical connection. The cup holder includes a bottom cover 232. The bottom cover 232 is provided with an avoidance hole 2321 for avoiding the upper coupler 26, and a push rod 2322 for triggering a switch installed in the host. A rotating bracket is provided above the bottom cover 232. 24. The rotating bracket 24 is provided with a gap to avoid the upper coupler 26, and the gap is prov...

Embodiment 3

[0063] The difference between this embodiment and the first embodiment is that the upper positioning structure is a through hole provided on the rotating bracket, and the lower positioning structure is a bump on the main machine.

[0064] In this example, if Figure 12-Figure 15 As shown, the cup holder includes a mounting base 231 and a bottom cover 232, the rotating bracket 24 is rotatably mounted on the bottom of the mounting base 231, the upper positioning structure is a through hole 2412 located in the rotating bracket, and the bottom cover 232 is provided with an avoidance of the lower positioning structure. Hole 2321, the main machine 10 is provided with the lower connector 12, the lower coupler 113 and the lower positioning structure connected with the transmission of the crushing knife assembly. Stroke, the bump 112 is opposite to the through hole 2412. At this time, when the stirring cup is installed, the bump 112 extends into the cup holder and is inserted into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com