Corona ring and electrostatic powder spray gun

A technology of electrostatic spray gun and corona ring, applied in the direction of spray electric energy device, spray discharge device, etc., can solve the problems of easy to be stained with powder and affect the effect of electricity absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

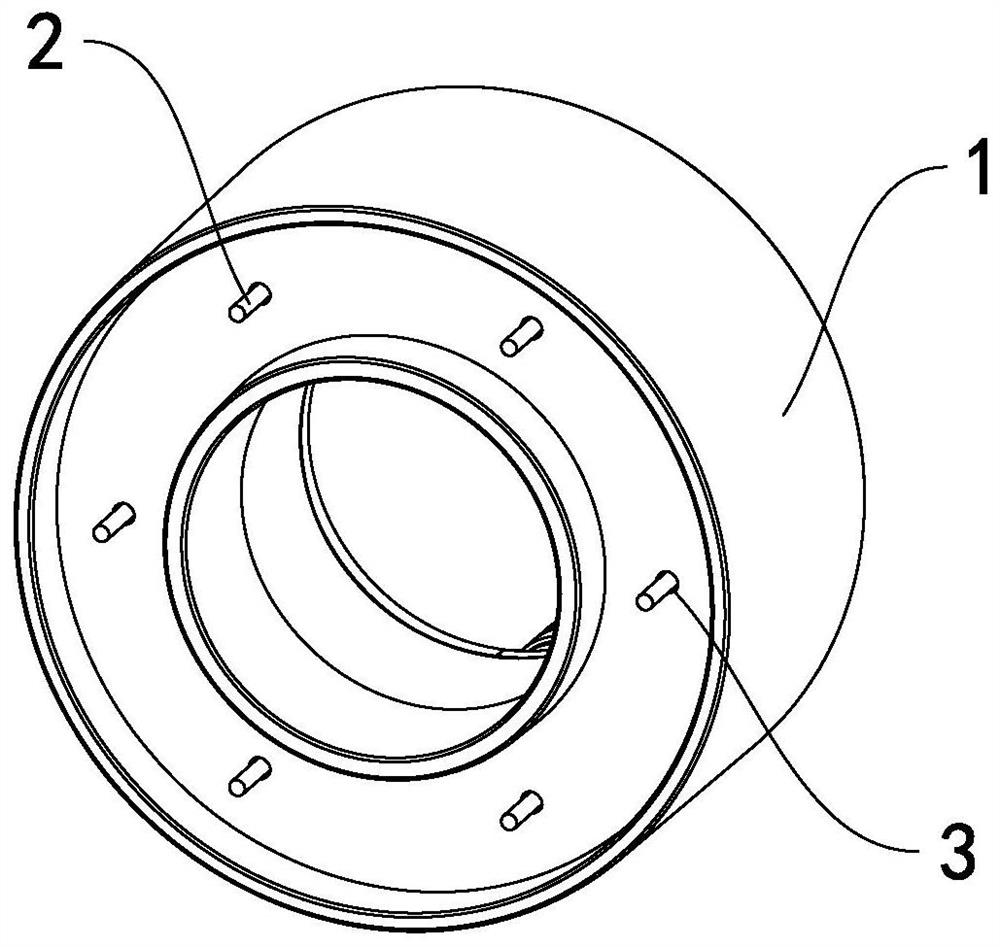

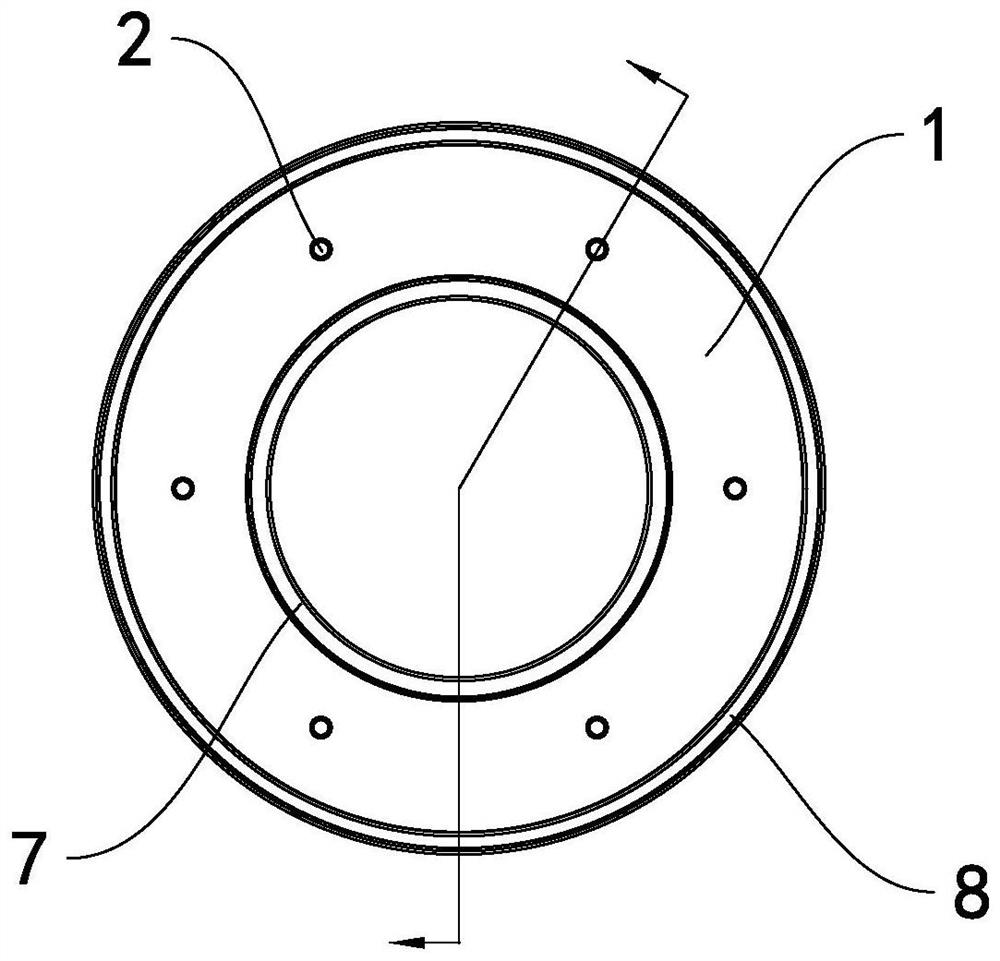

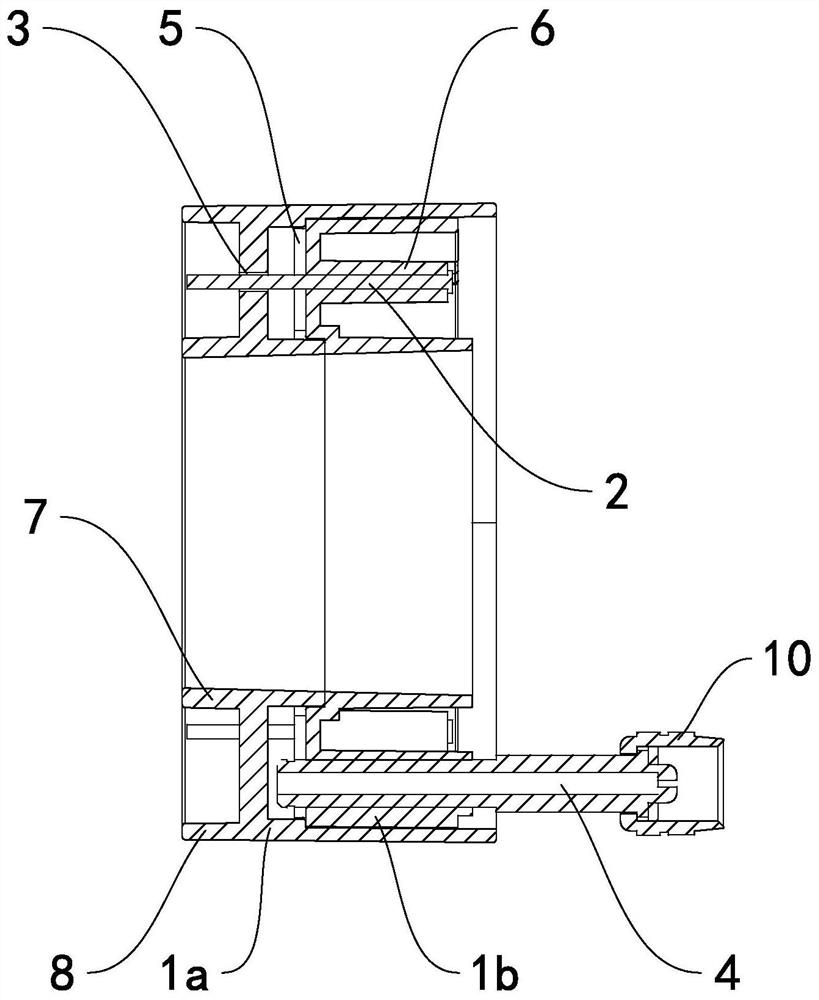

[0033] A corona ring such as figure 1 The first embodiment of the invention is shown: it includes a ring housing 1 and a plurality of electricity-absorbing needles 2, the plurality of electricity-absorbing needles 2 are regularly arranged in a circular ring, and the plurality of electricity-absorbing needles 2 take the axial direction of the ring housing 1 as Evenly distributed in the center. The electricity-absorbing needles 2 are grounded, and the exposed part thereof will attract the corona of high-voltage static electricity radiated from the muzzle. The plurality of electricity-absorbing needles 2 attract electric charges at the same time, which can evenly and weaken the environmental magnetic field.

[0034] One end of the electricity-absorbing needle 2 is fixedly installed in the ring casing 1 , the upper surface of the ring casing 1 is provided with an air hole 3 , and the other end of the electricity-absorbing needle 2 penetrates out of the ring casing 1 through the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com