A pearl cleaning and screening equipment for jewelry processing

A screening equipment and pearl technology, applied in the field of pearl cleaning and screening equipment, can solve problems such as affecting the work progress and being easily fatigued.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

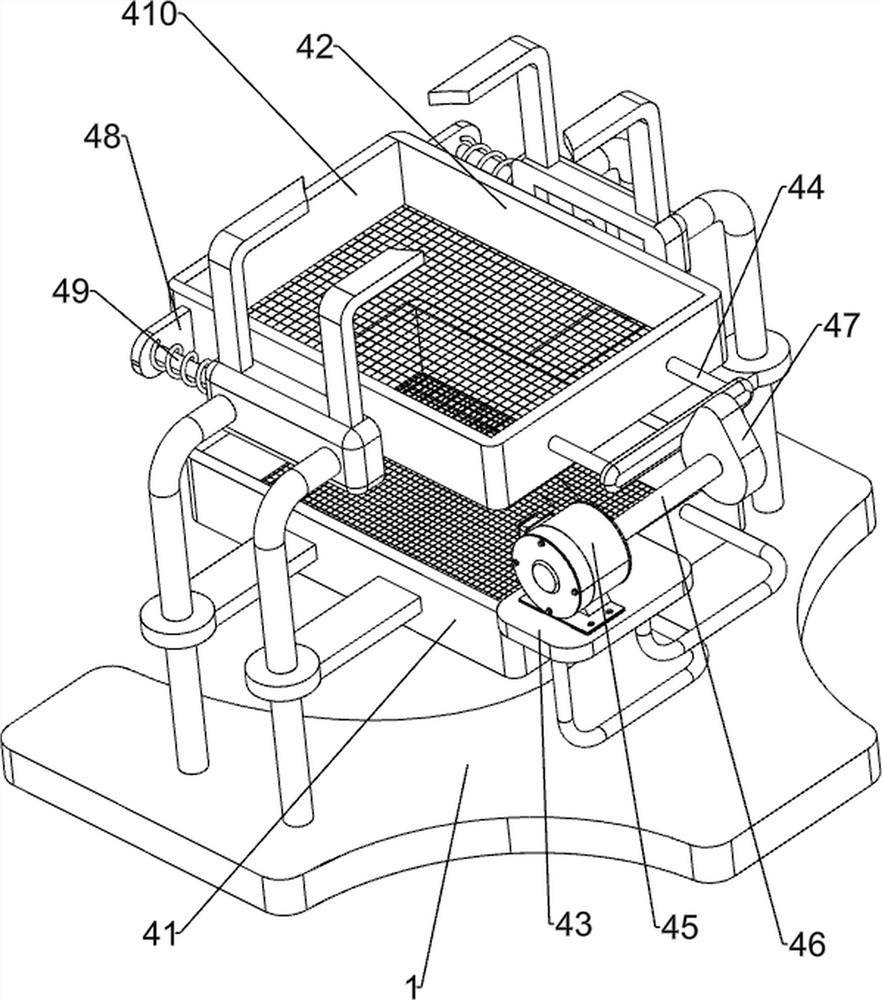

[0067] A pearl cleaning and screening equipment for jewelry processing, such as figure 1As shown, it includes a base 1, a material control mechanism 2, a cleaning mechanism 3 and a screening mechanism 4. There is a material control mechanism 2 on the inner side of the upper part of the base 1, and a cleaning mechanism 3 is arranged between the front and rear sides of the upper part of the base 1. A screening mechanism 4 is arranged between the front and rear sides of the upper side of the seat 1 .

[0068] When people need to screen and clean pearls, they can use this pearl cleaning and screening equipment for jewelry processing. First, people need to pour the pearls into the material control mechanism 2, and then inject water into the material control mechanism 2, and then start the cleaning mechanism 3, The cleaning mechanism 3 rotates to clean the pearls. After cleaning, the cleaning mechanism 3 can be closed. People then pull the material control mechanism 2 to move back, ...

Embodiment 2

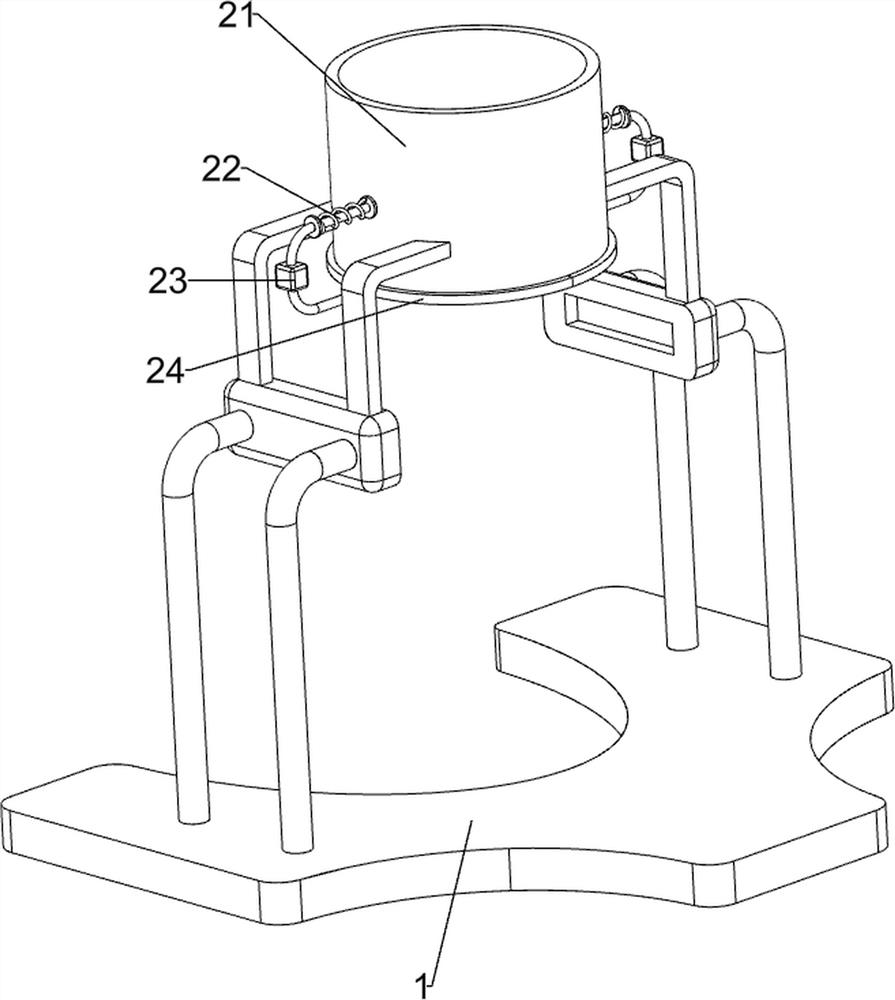

[0070] On the basis of Example 1, as Figure 2-Figure 4 As shown, the material control mechanism 2 includes a cleaning box 21, a first telescopic assembly 22, a first connecting rod 23 and a baffle plate 24. A cleaning box 21 is provided on the inner side of the upper part of the base 1. A first telescopic assembly 22 is provided, a first connecting rod 23 is disposed outside the first telescopic assembly 22 , and a baffle plate 24 is disposed inside the first connecting rod 23 , and the baffle plate 24 is slidably connected to the cleaning box 21 .

[0071] People need to pour the pearls into the cleaning box 21, and then inject water into the cleaning box 21. When the cleaning mechanism 3 is activated, the pearls can be cleaned. After cleaning, people manually pull the first connecting rod 23 to move back, and the first The telescopic assembly 22 is stretched, thereby driving the baffle plate 24 to move back, allowing the pearls to fall into the screening mechanism 4, which ...

Embodiment 3

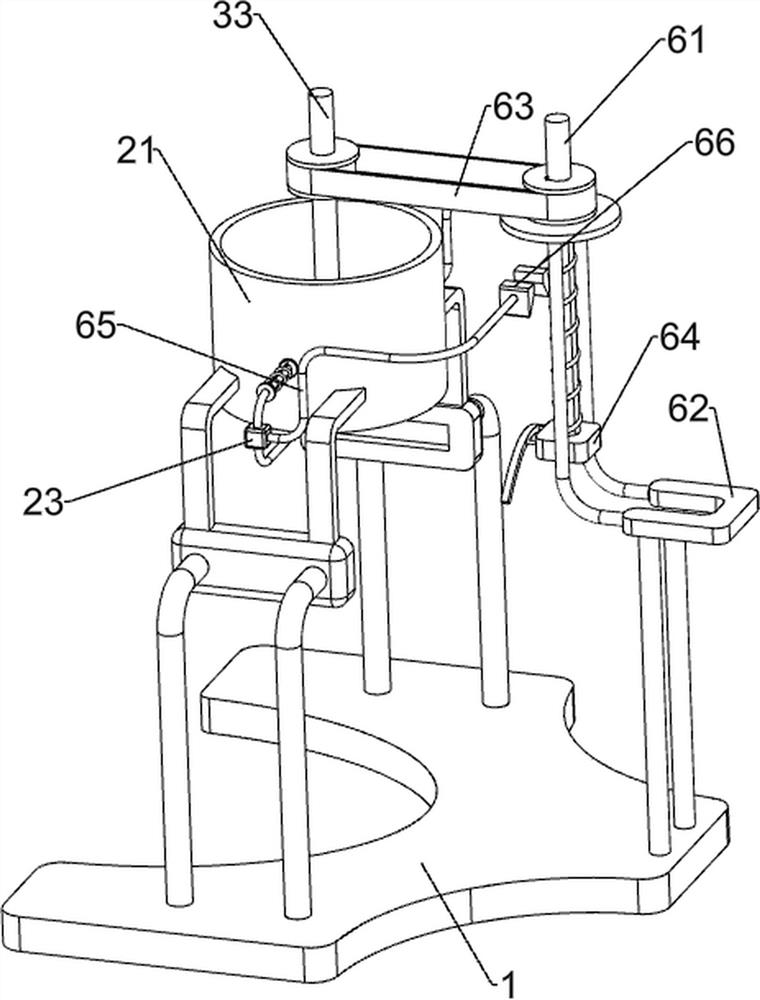

[0077] On the basis of Example 2, as Figure 5-Figure 7 As shown, it also includes a valve control mechanism 5. The valve control mechanism 5 includes a rotating mandrel 51, a third support frame 52, a cleaning agent bottle 53, a second connecting rod 54 and a valve 55. The first rotating shaft 33 is provided with a rotating On the top rod 51 , two third support frames 52 are arranged at intervals on the right side of the top of the cleaning box 21 , a cleaning agent bottle 53 is arranged inside the upper side of the third support frame 52 , and a second connecting rod 54 is arranged on the upper right side of the third support frame 52 , a valve 55 is slidably provided between the second connecting rod 54 and the lower side of the cleaning agent bottle 53 .

[0078] People first pour the cleaning agent into the cleaning agent bottle 53. When the first rotating shaft 33 rotates, the first rotating shaft 33 rotates and drives the rotating mandrel 51 to rotate. When the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com