Efficient scissor foot assembling equipment

A technology for assembling equipment and scissors legs, applied in the field of scissors legs, can solve the problems of inconvenient, time-consuming, labor-intensive, and unsatisfactory holding and clamping by human hands, saving manpower and material resources, improving assembly effects, and improving production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

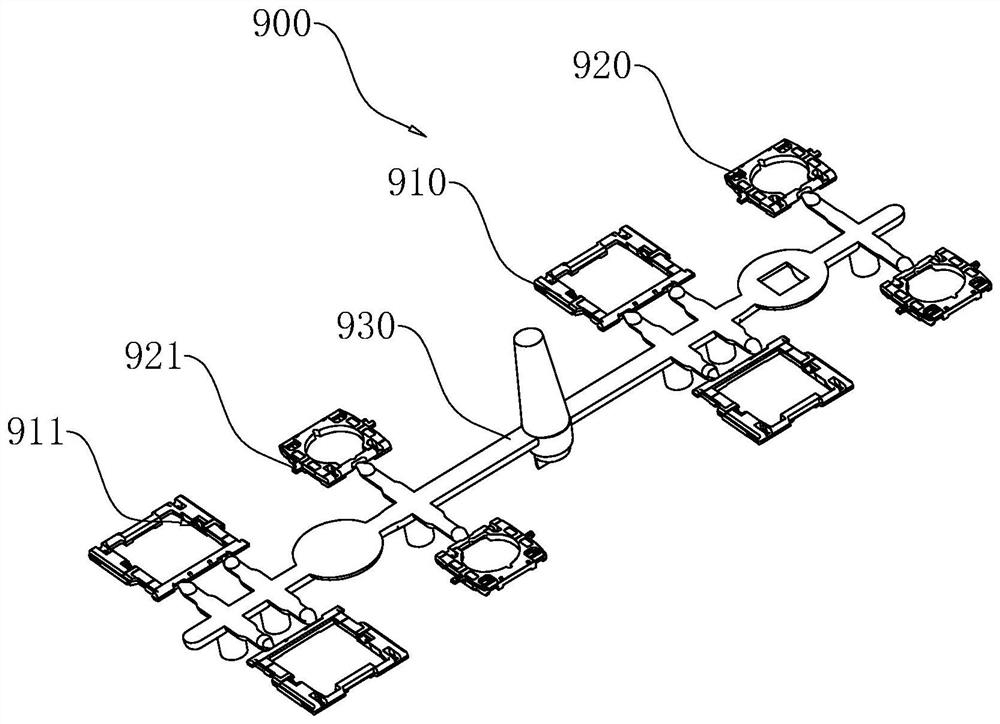

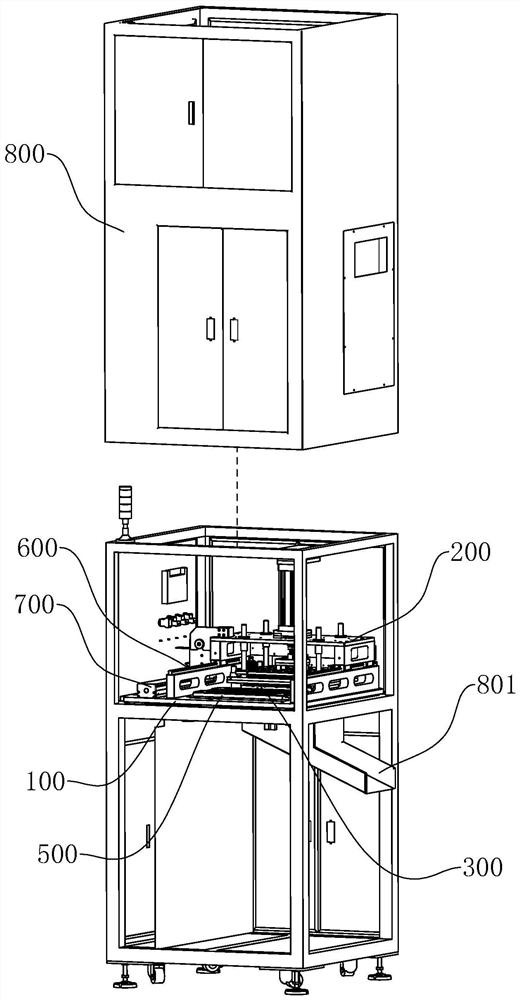

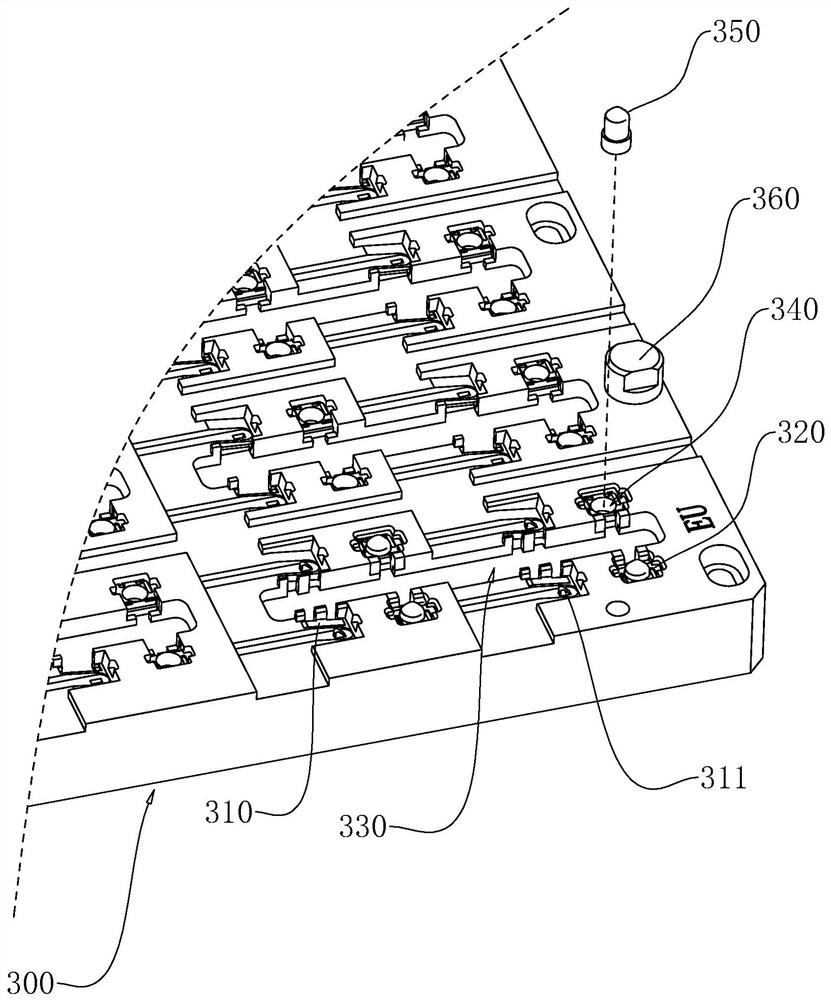

[0045] The present application discloses a high-efficiency assembly equipment of scissor legs, which is used for cutting the outer frame 910 and the inner frame 920 of the batching unit 900 from the connecting rod 930 and assembling them together. refer to figure 1 , in this embodiment, the batching unit 900 includes a connecting rod 930 , four outer frames 910 and four inner frames 920 . The four outer frames 910 are symmetrically connected in pairs on opposite sides of the connecting rod 930 ; similarly, the four inner frames 920 are connected in pairs on opposite sides of the connecting rod 930 in a symmetrical manner. On the same side of the connecting rod 930, the outer frame 910 and the inner frame 920 are arranged alternately. At the same time, the inner frame 920 is provided with a pair of rotating shafts 921, and the two rotating shafts 921 are arranged symmetrically on opposite sides of the outer ring of the inner frame 920; Both sides; the shaft groove 911 is used...

Embodiment 2

[0074] The embodiment of the present application discloses an efficient assembly equipment for scissor legs. This embodiment is basically the same as Embodiment 1, the difference is that, with reference to Figure 9 , a baffle 770 is provided on one side of the slide table 730; meanwhile, the workbench 100 is fixedly connected with a laser range finder 780 that cooperates with the baffle 770. The laser rangefinder 780 emits light to the baffle 770 and measures the distance between the two, through which the moving distance of the press-cut assembly 200 in the direction along the slide rail 600 can be accurately judged, so that the press-cut assembly 200 can be precisely positioned, Make the assembly of the inner frame 920 and the outer frame 910 more smooth. Moreover, compared with Embodiment 1, the positioning of the laser rangefinder 780 does not need to be limited by the number and position of the U-shaped groove photoelectric switches 760, so the positioning is more flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com