Machining equipment and machining method for bearing outer ring

A technology of bearing outer ring and processing equipment, applied in the field of bearings, can solve the problems of long production cycle, reduce production capacity, increase production cost, etc., and achieve the effect of simplifying production process, reducing production cycle and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

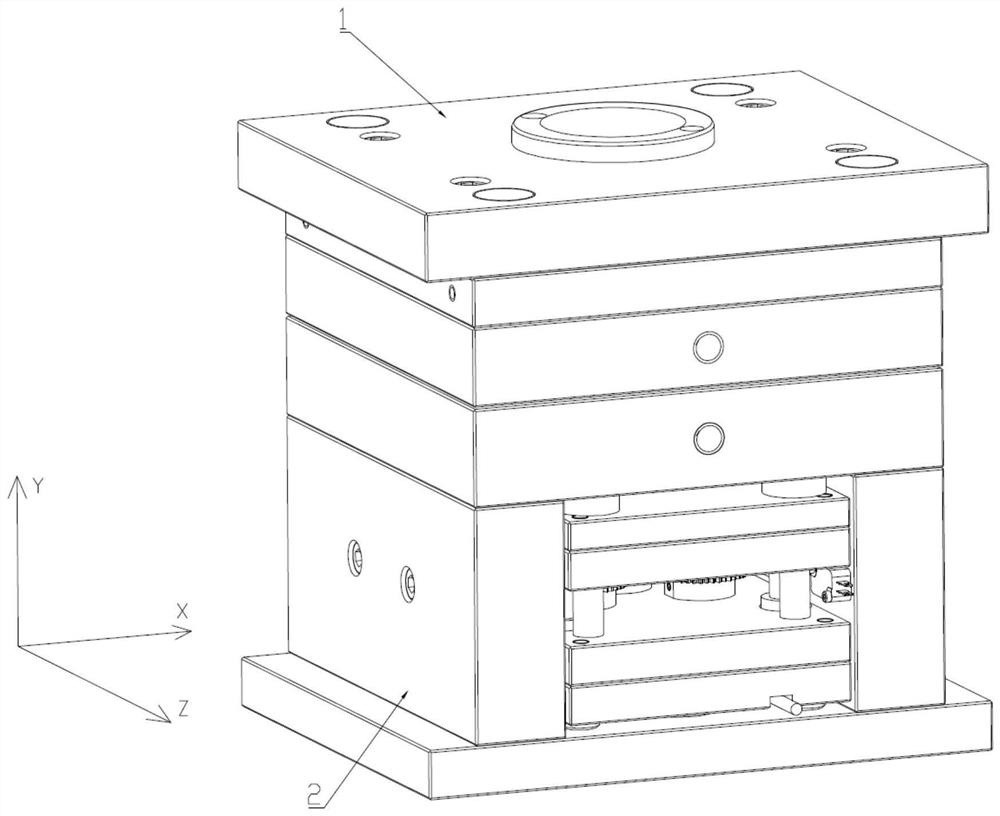

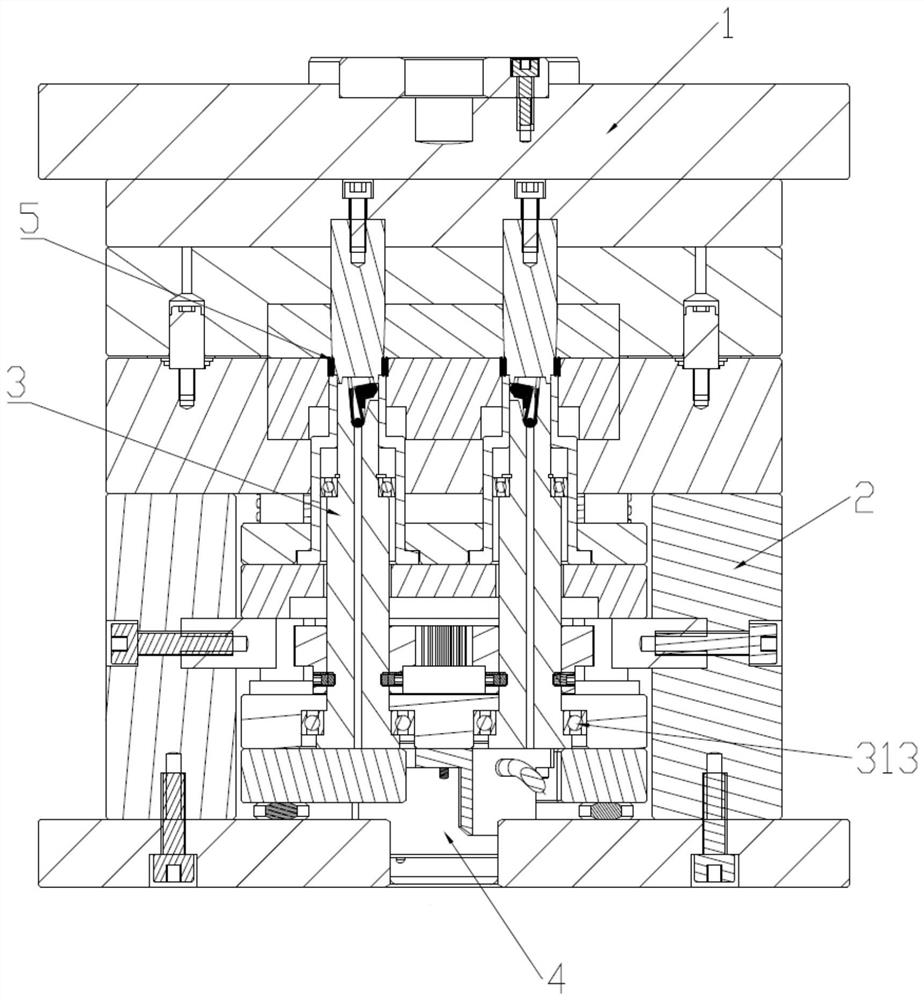

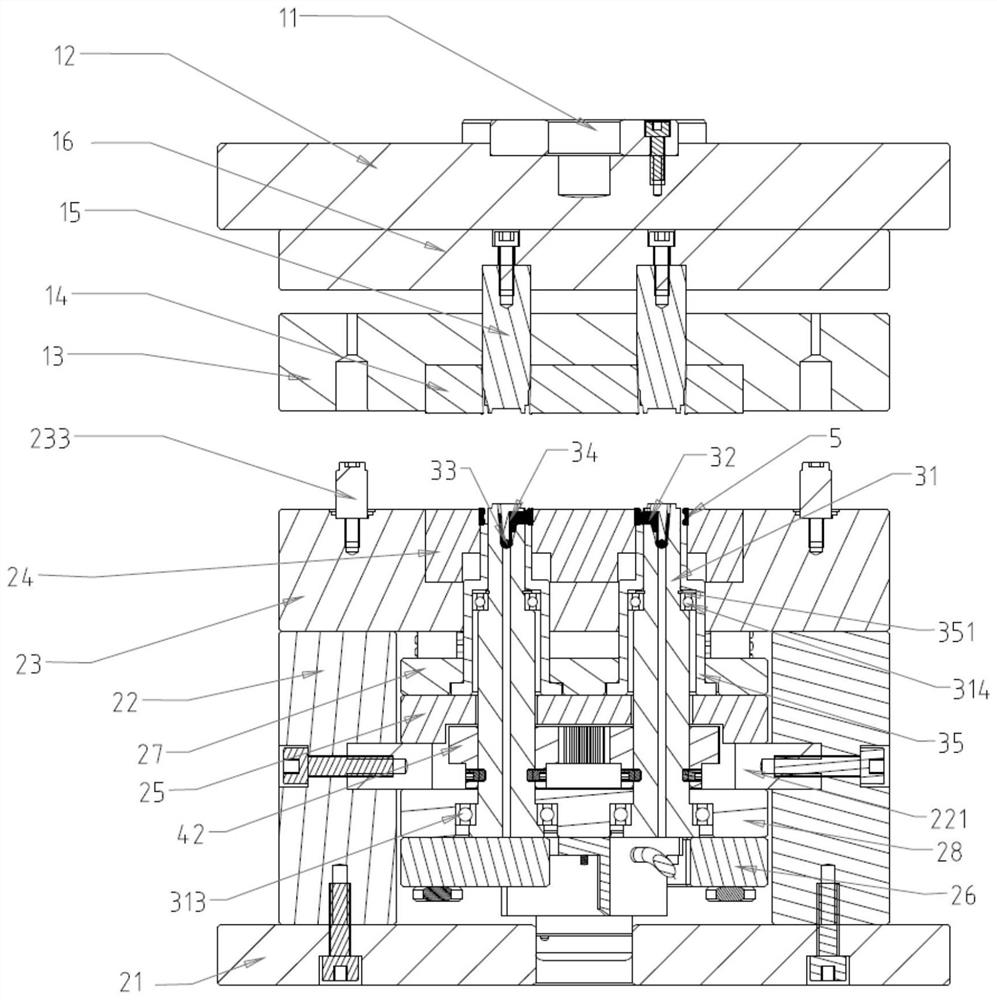

[0049] Such as Figure 1-3 As shown, a processing equipment for the outer ring of a bearing, including an upper die set 1, a lower die set 2 and a lathe assembly; wherein the upper die set 1 is set above the lower die set 2; the upper die set 1 and the lower die set 2 are molded When forming a cavity without an inner arc groove, mold closing means that the upper die set 1 and the lower die set 2 are bonded together; Group 1 can slide up and down relative to lower die set 2, so that upper die set 1 and lower die set 2 can be bonded and separated; lathe assembly is set on lower die set 2; sliding assembly and lathe assembly are flexibly connected; upper die set 1 drives When the sliding component is far away from the turning component, the turning component reaches the set position, and the turning component is used to complete the cutting process of the inner arc groove of the bearing outer ring 5

[0050] The lathe assembly includes a motor module 4 and a tool rest 3, wherein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com