An ultra-light, heat-insulating and erosion-resistant functionally integrated composite material and its preparation method

A composite material and ceramic composite material technology, applied in the field of lightweight special material development, can solve the problems of limited light weight and high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

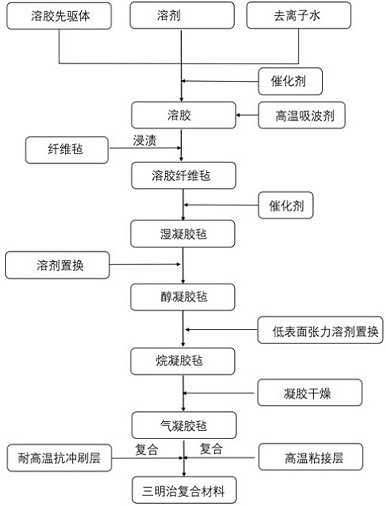

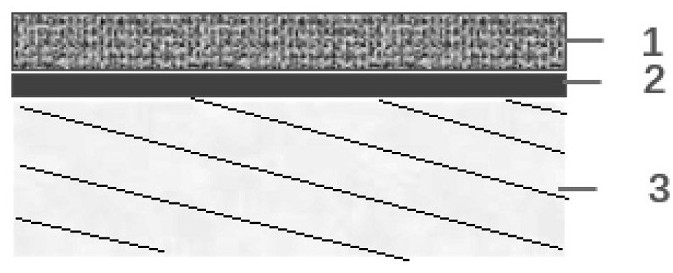

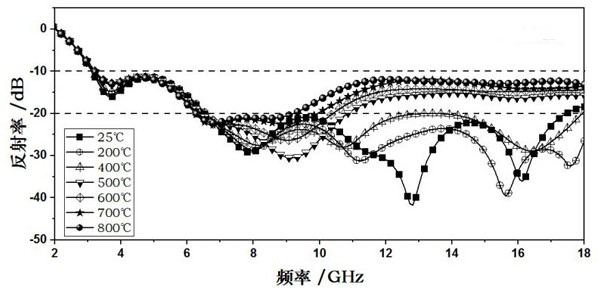

[0071] A light-weight thermal insulation and erosion-resistant integrated composite material based on high-temperature wave absorption, the preparation process of which is as follows:

[0072] 1) Preparation of the outer layer of the heat-resistant structure with high temperature resistance and erosion resistance:

[0073] Fiber-reinforced ceramic matrix composites are prepared according to requirements; the alumina preform is a continuous alumina fiber cloth, and the alumina cloth is a satin cloth (its density is 0.9g / cm 3 ) with a thickness of 0.61mm.

[0074] The substrate is prepared by slurry impregnation and sintering method, and the impregnated ceramic slurry is made of Y 2 O 3 , ZrO 2 , SiO 2 , Al 2 O 3 , TiO 2 According to the mass ratio of 1:1:1:1:1 mixture, the particle size of the ceramic powder is 0.5 microns.

[0075] The thickness of the outer layer of the heat-resistant structure with high temperature resistance and erosion resistance is 0.65mm. Its de...

Embodiment 2

[0094] Other conditions are consistent with embodiment 1; the difference is:

[0095] 3) Preparation of high temperature adhesive

[0096] The high temperature adhesive is prepared by mixing and stirring polyazane silicon precursor, titanium alloy powder, silicon carbide powder and dispersant in a mass ratio of 35:30:30:5. The particle size of titanium alloy powder and silicon carbide powder is 1-2 microns; the dispersant is acrylic resin;

[0097] The properties of the obtained materials are shown in Table 2.

Embodiment 3

[0099] Other conditions are consistent with embodiment 1; the difference is:

[0100] 3) Preparation of high temperature adhesive

[0101] The high temperature adhesive is prepared by mixing and stirring polyazane silicon precursor, titanium alloy powder, silicon carbide powder and dispersant in a mass ratio of 80:15:4.5:0.5. The particle size of titanium alloy powder and silicon carbide powder is 1-2 microns; the dispersant is acrylic resin;

[0102] The properties of the obtained materials are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com