Ultra-light heat-insulating and scouring-resistant functional integrated composite material and preparation method thereof

A technology of composite materials and ceramic composite materials, which is applied in the field of development of lightweight special materials, can solve the problems of light weight and limited high temperature resistance, and achieve the effects of avoiding hidden dangers in performance, realizing light weight and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

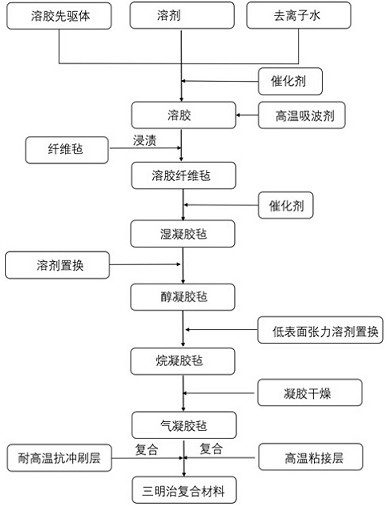

Method used

Image

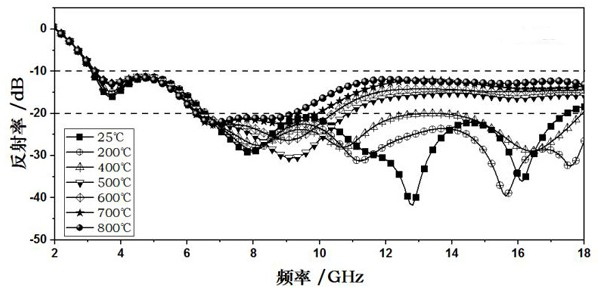

Examples

Embodiment 1

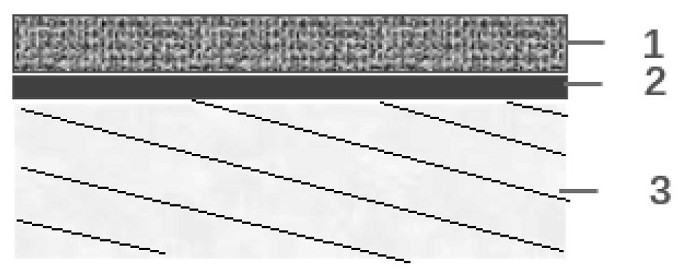

[0071] A light-weight heat-insulating and erosion-resistant integrated composite material based on high-temperature wave absorption, the preparation process of which is as follows:

[0072] 1) Preparation of the outer layer of the heat-resistant structure with high temperature resistance and erosion resistance:

[0073] Prepare fiber-reinforced ceramic matrix composites according to requirements; the alumina preform is continuous alumina fiber cloth, and the alumina cloth is satin cloth (its density is 0.9g / cm 3 ), with a thickness of 0.61mm.

[0074] The preparation of the matrix adopts the slurry impregnation sintering method, and the ceramic slurry is impregnated with Y 2 o 3 , ZrO 2 , SiO 2 、Al 2 o 3 、TiO 2 According to the mixture with a mass ratio of 1:1:1:1:1, the particle size of the ceramic powder is 0.5 microns.

[0075] The thickness of the outer layer of the heat-resistant structure with high temperature resistance and erosion resistance is 0.65mm. Its den...

Embodiment 2

[0094] Other conditions are consistent with embodiment 1; The difference is:

[0095] 3) Preparation of high temperature adhesive

[0096] The high-temperature adhesive is prepared by mixing and stirring polyazane-silicon precursor, titanium alloy powder, silicon carbide powder, and dispersant at a mass ratio of 35:30:30:5. Wherein the particle size of the titanium alloy powder and the silicon carbide powder is 1 to 2 microns; the dispersant is an acrylic resin;

[0097] The properties of the obtained materials are shown in Table 2.

Embodiment 3

[0099] Other conditions are consistent with embodiment 1; The difference is:

[0100] 3) Preparation of high temperature adhesive

[0101] The high-temperature adhesive is prepared by mixing and stirring polyazane-silicon precursor, titanium alloy powder, silicon carbide powder, and dispersant in a mass ratio of 80:15:4.5:0.5. Wherein the particle size of the titanium alloy powder and the silicon carbide powder is 1 to 2 microns; the dispersant is an acrylic resin;

[0102] The properties of the obtained materials are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com