Silicon nitride and silicon carbide combined composite ceramic as well as preparation method and application thereof

A technology of composite ceramics and silicon carbide, which is applied in the fields of ceramic products, applications, and other household appliances, etc., can solve the problems that composite materials do not have the performance of electromagnetic protection, achieve excellent high-temperature wave-absorbing performance, and the overall process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The following exemplifies the preparation method of the silicon nitride combined silicon carbide composite ceramic for electromagnetic protection provided by the present invention, and the preparation method mainly includes the following steps.

[0027] Raw materials are mixed. SiC, Si and β-Si 3 N 4 The powders are uniformly mixed to form a raw material powder, and an appropriate amount of catalyst is added to the raw material powder to be uniformly mixed.

[0028] The raw material powder can be a commercial powder with a purity of >99%. In some embodiments, based on the total mass of the raw material powder being 100 wt %, the proportion of SiC powder may be 20-50 wt %; Si powder is used as a raw material for reacting with nitrogen, β-Si 3 N 4 The powder is used as a seed crystal for promoting grain growth, and the total content of the two can be 50-80 wt %. Among them, β-Si 3 N 4 The powder can account for 1-10wt% of its total mass with Si powder.

[0029] Pr...

Embodiment 1

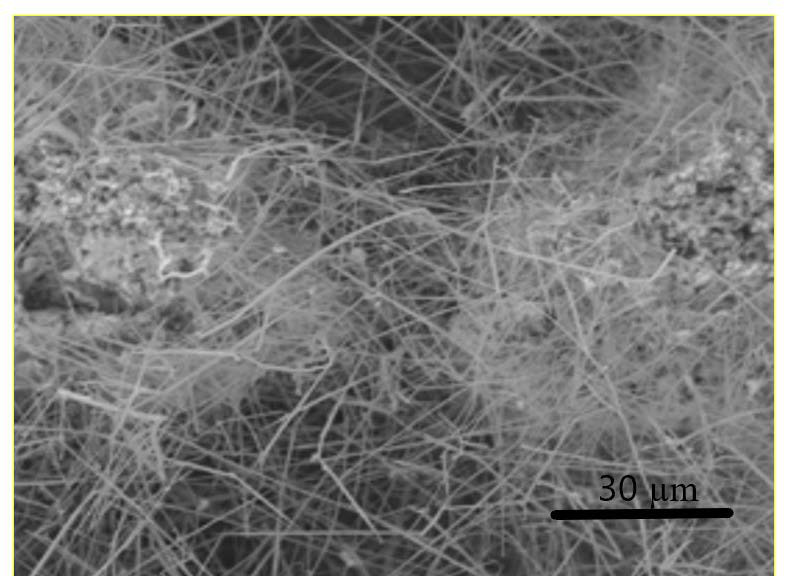

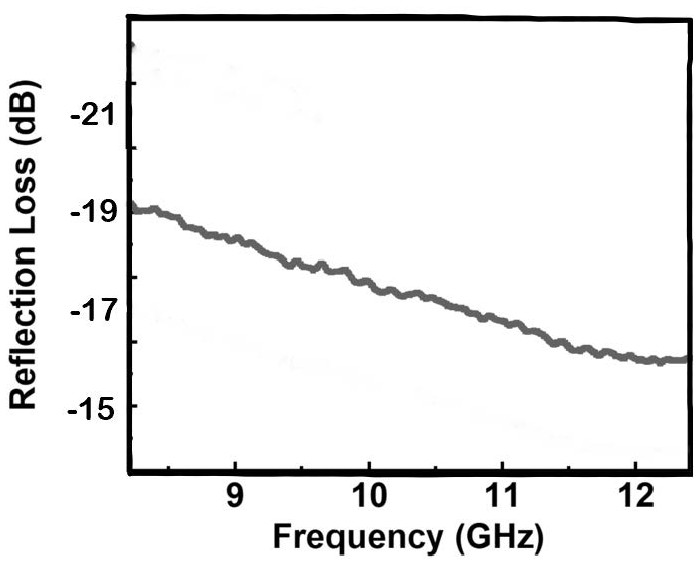

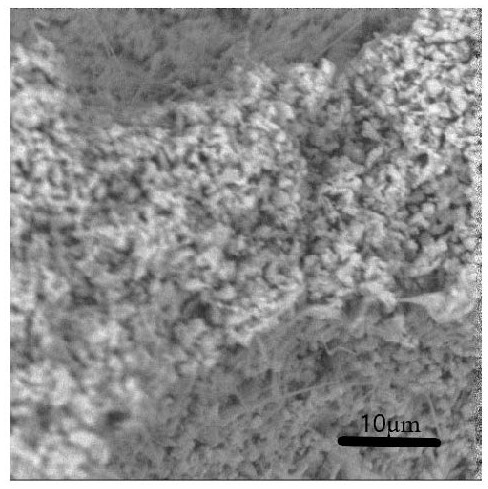

[0047] Take 5g and 15g of SiC powder with a median particle size of 0.1 microns and 5 microns, respectively, 75 g of Si powder with a median particle size of 0.5 microns, and β-Si with a median particle size of 3 microns. 3 N 4 Mix 5g powder and 0.1g molybdenum oxide powder. 80g of PVB powder is used as a binder, which is thoroughly mixed and dissolved with 260g of alcohol. 200g of silicon carbide grinding balls and the aforementioned powder are ball-milled and mixed in a planetary ball mill for 4 hours at a rotational speed of 300r / min to obtain a slurry with uniform composition. After drying, the slurry is passed through a 200-mesh sieve to obtain a mixed powder with uniform components, which is dry-pressed into a green sample with a length of 40mm*width 8mm*8mm high, and the molding pressure is 0.07MPa. The degreasing process is as follows: the green body is heated from 300 ° C to 600 ° C, and the heating time is controlled to 3 hours to ensure the full decomposition of th...

Embodiment 2

[0051] Take 5g and 15g of SiC powder with a median particle size of 0.1 microns and 5 microns, respectively, 75 g of Si powder with a median particle size of 0.5 microns, and β-Si with a median particle size of 3 microns. 3 N 4 Mix 5g powder and 0.1g molybdenum oxide powder. 30g of PVB powder is used as a binder, which is thoroughly mixed and dissolved with 130g of alcohol. 200g of silicon carbide grinding balls and the aforementioned powder are ball-milled and mixed in a planetary ball mill for 6 hours at a rotational speed of 300r / min to obtain a slurry with uniform composition. After drying, the slurry is passed through a 200-mesh sieve to obtain a mixed powder with uniform components, which is dry-pressed into a blank sample of φ60mm*10mm with a molding pressure of 0.1MPa and degreasing. The degreasing process is: The temperature was raised to 600°C, and the heating time was controlled to 1 hour to ensure the sufficient decomposition of the binder and the integrity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com