Liquid crystal polyester film, preparation method, application and circuit board preparation method

A liquid crystal polyester and film technology, applied in circuit substrate materials, printed circuit manufacturing, printed circuits, etc., can solve problems such as high product anisotropy, poor product tear strength, and low product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

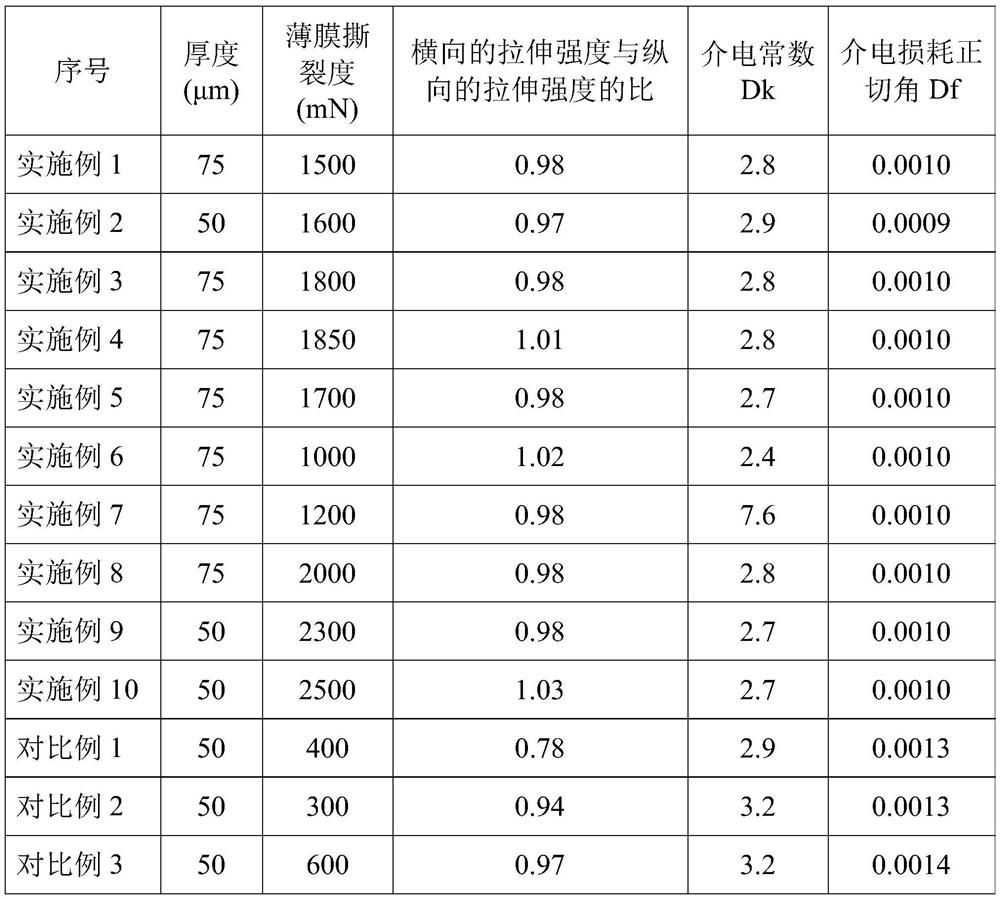

Examples

manufacture example 1

[0076] Production Example 1: Preparation of Liquid Crystal Polyester Fiber

[0077] The preparation of liquid crystal polyester fiber comprises the following steps:

[0078] In a reactor equipped with a stainless steel C-type stirrer, torque gauge, nitrogen conduit, thermometer, pressure gauge and reflux condenser, 1027.5 g of 4-hydroxybenzoic acid (HBA), 470 g of 6-hydroxy-2-naphthalene Formic acid (HNA), the acetic anhydride of 1122g, the acetic acid of 200.0g, this reactor is purified by the mode of vacuumizing and dry nitrogen flushing, add the 1-methylimidazole of 0.3g, under the protection of nitrogen, at 150 rpm Stir at a speed of 1 minute, raise the temperature to 150°C over 60 minutes, and reflux at this temperature for 60 minutes. After adding 13.0g of phenol into the reactor, raise the temperature to 340°C within 120 minutes. During this period, by distillation Remove the by-product acetic acid, keep the temperature at 340°C for 30 minutes, gradually reduce the pre...

manufacture example 2

[0082] Manufacturing Example 2: Preparation of Liquid Crystal Polyester Fiber

[0083] The preparation of liquid crystal polyester fiber comprises the following steps:

[0084] In a reactor equipped with a stainless steel C-type stirrer, torque gauge, nitrogen conduit, thermometer, pressure gauge and reflux condenser, 994.5 g of p-hydroxybenzoic acid, 299.0 g of terephthalic acid, 99.7 g of isophthalic acid Diformic acid, 446.9g of 4,4'-dihydroxybiphenyl, 1347.6g of acetic anhydride, 200.0g of acetic acid, purify the reactor by vacuuming and flushing with dry nitrogen, add 0.18g of 1-methanol For imidazole, under nitrogen protection, stir at a speed of 75 rev / min, raise the temperature to 150°C over 60 minutes, and reflux at this temperature for 60 minutes, add 13.0g benzylamine and 1.84g calcium acetate to the reactor After that, the temperature was raised to 340°C within 20 minutes, during which the by-product acetic acid was removed by distillation, and after 30 minutes at...

Embodiment 1

[0088] Embodiment 1: the preparation of liquid crystal polyester film

[0089] A liquid crystal polyester film, by weight, comprises the following components:

[0090] Class A liquid crystal polyester fiber X1 (L A A =9μm) 30 parts,

[0091] Class B liquid crystal polyester fiber X1 (L B = 1 ~ 10mm, D B =9μm) 70 parts;

[0092] The A-type liquid crystal polyester fiber X1 and the B-type liquid crystal polyester fiber X1 are obtained by shearing the liquid crystal polyester fiber X1 prepared in Production Example 1.

[0093] A preparation method of a tear-resistant liquid crystal polyester film, comprising the following steps:

[0094] (1) Mix A-type liquid crystal polyester fiber X1, B-type liquid crystal polyester fiber X1 with water (the mass ratio of the total mass of A-type liquid-crystal polyester fiber X1 and B-type liquid-crystal polyester fiber X1 to water is 0.1: 100), prepared slurry C1;

[0095] (2) According to the papermaking process, the slurry C1 is copie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com