Device and method for adjusting working frequency band of frequency selective surface

A technology of frequency selection surface and working frequency band, which can be applied to antennas, electrical components, etc., and can solve the problems of difficulty in manufacturing, high cost, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

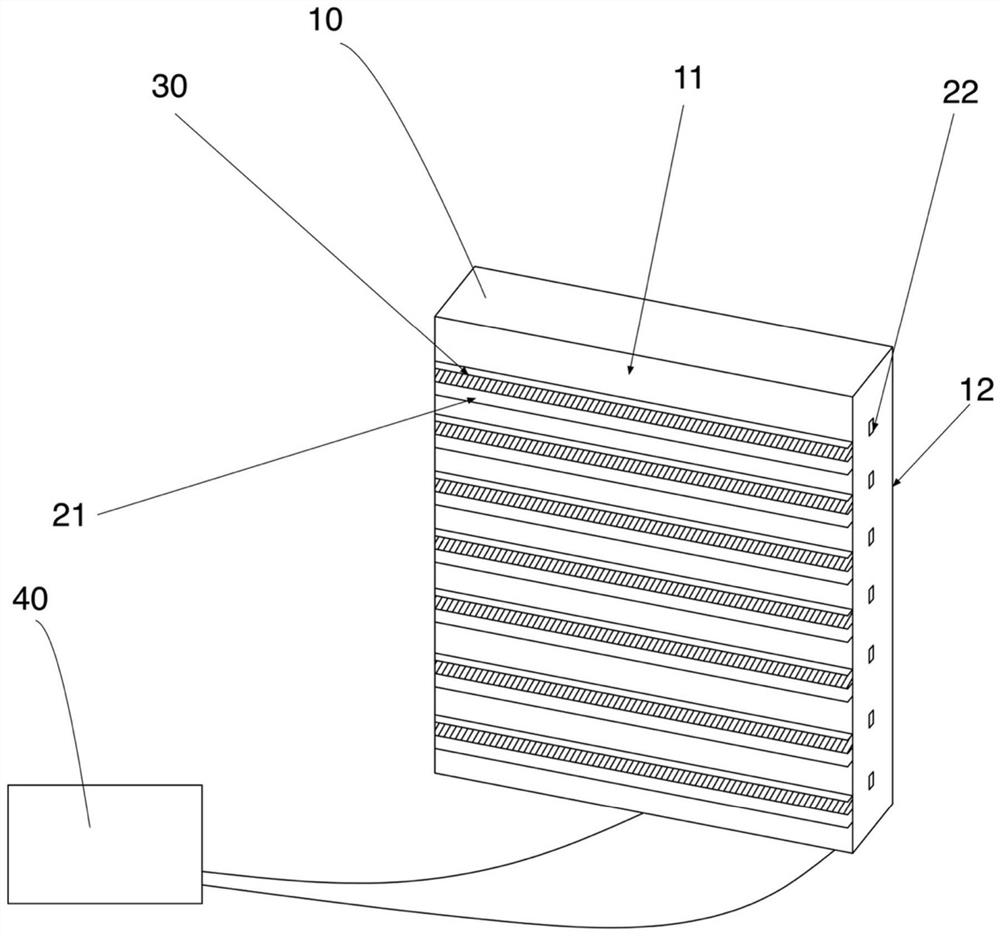

[0033] refer to figure 1 , the dielectric substrate 10 includes two first surfaces 11 and second surfaces 12 that are away from each other. In this embodiment, a number of first conductive units 21 are periodically arranged on the first surface 11 of the dielectric substrate 10 . The first conductive unit 21 can be a strip-shaped structure, and a plurality of first conductive units 21 are arranged in parallel on the first surface 11 at the same distance by printing. At this time, a frequency is formed on the first surface of the dielectric substrate 10. Select the surface. The dielectric constant of the dielectric substrate 10 can be selected according to the operating frequency range of the frequency selection surface.

[0034]The adjusting device provided in this embodiment is used to adjust the above-mentioned frequency selective surface, and mainly includes a plurality of second conductive units 22 and a high-voltage pulse power supply 40 .

[0035] A number of second co...

Embodiment 2

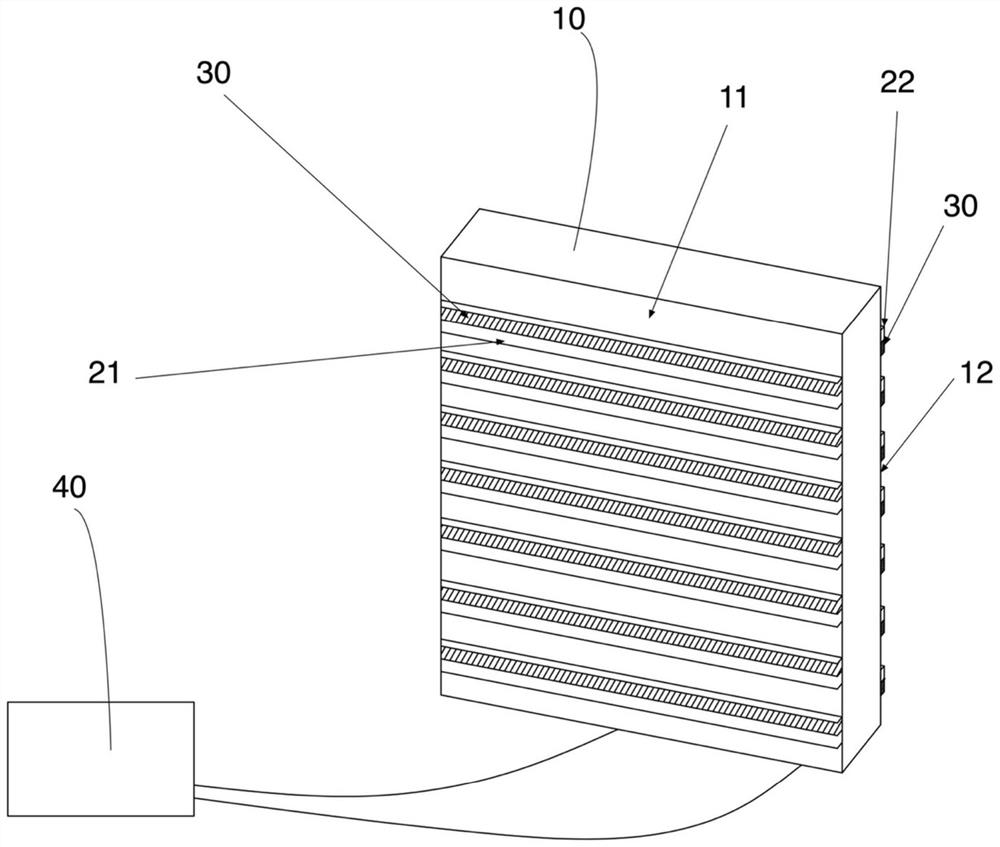

[0042] refer to figure 2 The only difference between the second embodiment and the first embodiment is that the second conductive unit 22 is arranged on the second surface 12 of the dielectric substrate 10 away from the first surface 11, and the high voltage pulse power supply 40 does not supply the first conductive unit 21. . When the second conductive unit 22 is powered on, the second surface 12 of the dielectric substrate 10 also forms a frequency selective surface.

[0043] After that, when the high-voltage pulse power supply 40 is powered on, the first surface 11 and the second surface 12 of the dielectric substrate 10 simultaneously form a frequency selective surface with a controllable operating frequency band.

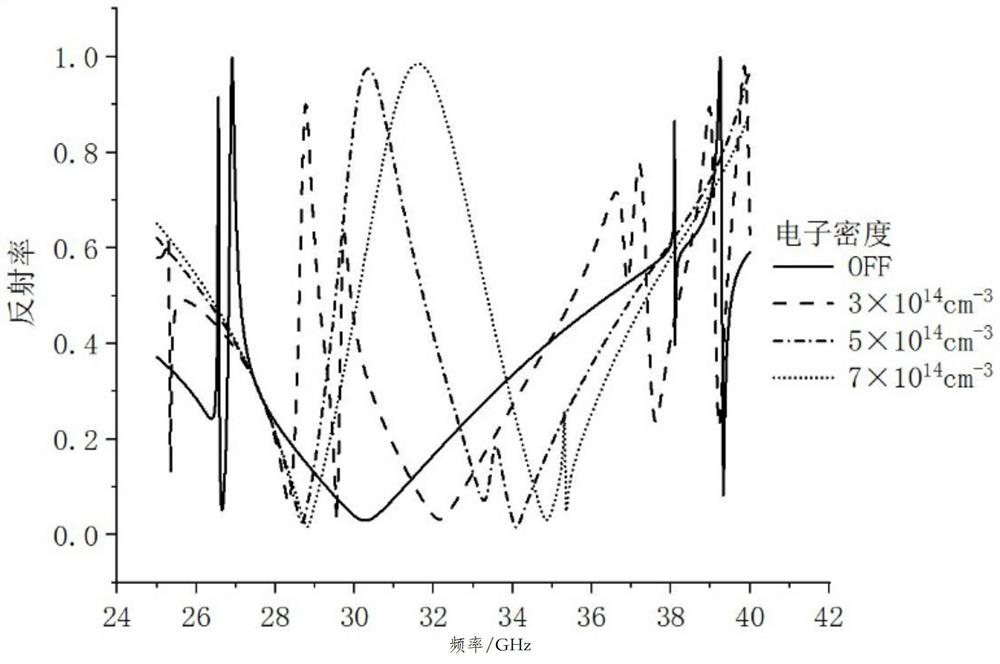

[0044] see Figure 5 and Image 6 , the two respectively show the structure provided by this embodiment, when the dielectric constant of the dielectric substrate 10 is 4.3, and the first conductive unit 21 and the second conductive unit 22 are made of metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com